Multi-coal special feeding device

A technology of feeding device and multi-type coal, applied in the direction of fuel supply, combustion method, block/powder supply/distribution, etc., can solve the problems of coal blocking, coal shedding, confluence, etc., so as to reduce equipment consumption and use. number, the effect of saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

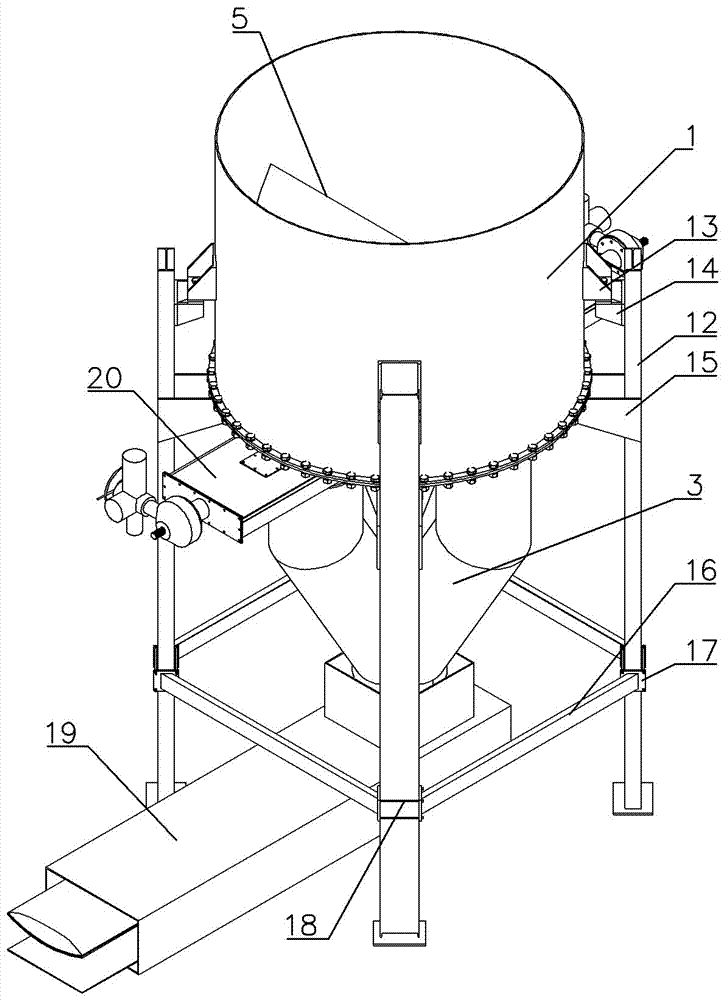

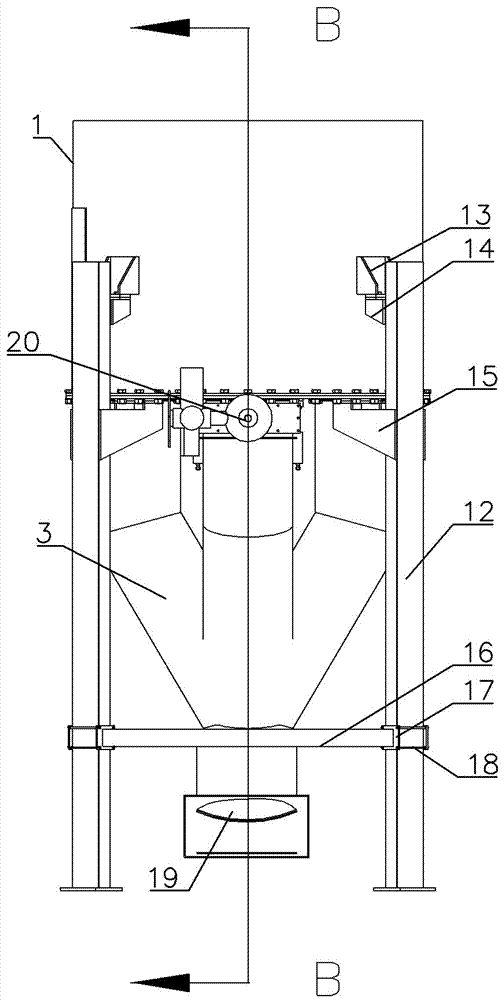

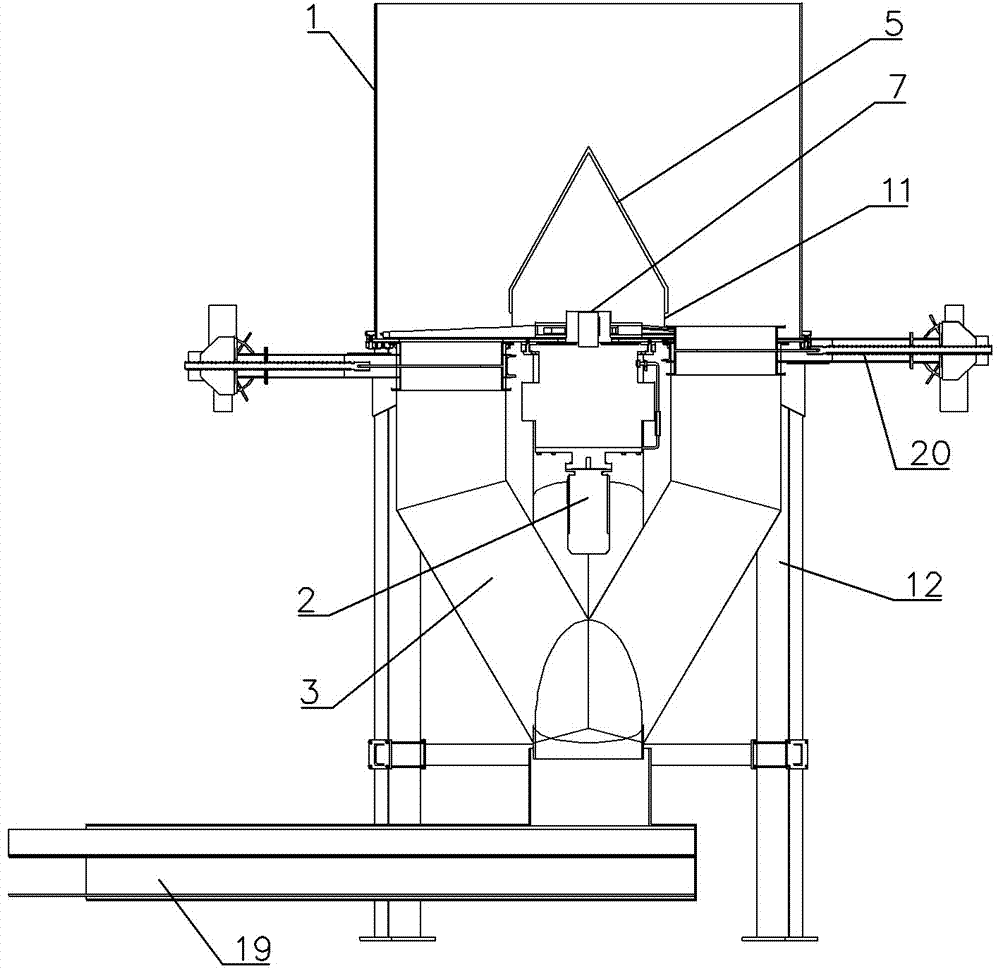

[0027] Multi-coal special feeding device, its structure is as follows Figure 1~5 As shown, it includes a coal bunker 1, a rotary cutting body, a power system 2 and a coal drop pipe 3.

[0028] The coal bunker 1 includes a side wall and a bottom plate made of NM400 wear-resistant material, and the side wall and the bottom plate of the coal bunker 1 are connected by a flange. The coal bunker 1 is provided with an inverted "V"-shaped splitter plate 5, and the two ends of the splitter plate 5 are fixed on the side wall of the coal bunker 1. The bottom plate of the coal bunker 1 is provided with four discharge ports 4, two discharge ports 4 Located below the diverter plate 5, the central connection line of the two discharge ports 4 is parallel to the ridge line of the diverter plate 5; the two discharge ports 4 are located on both sides of the diverter plate 5, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com