Air-conditioner fault self-examining method, tool and device

A fault self-inspection and tooling technology, applied in space heating and ventilation, space heating and ventilation control input, heating mode, etc., can solve problems such as difficult to quickly and accurately determine air-conditioning faults, to improve the speed and quality of solutions, The effect of easy connection tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

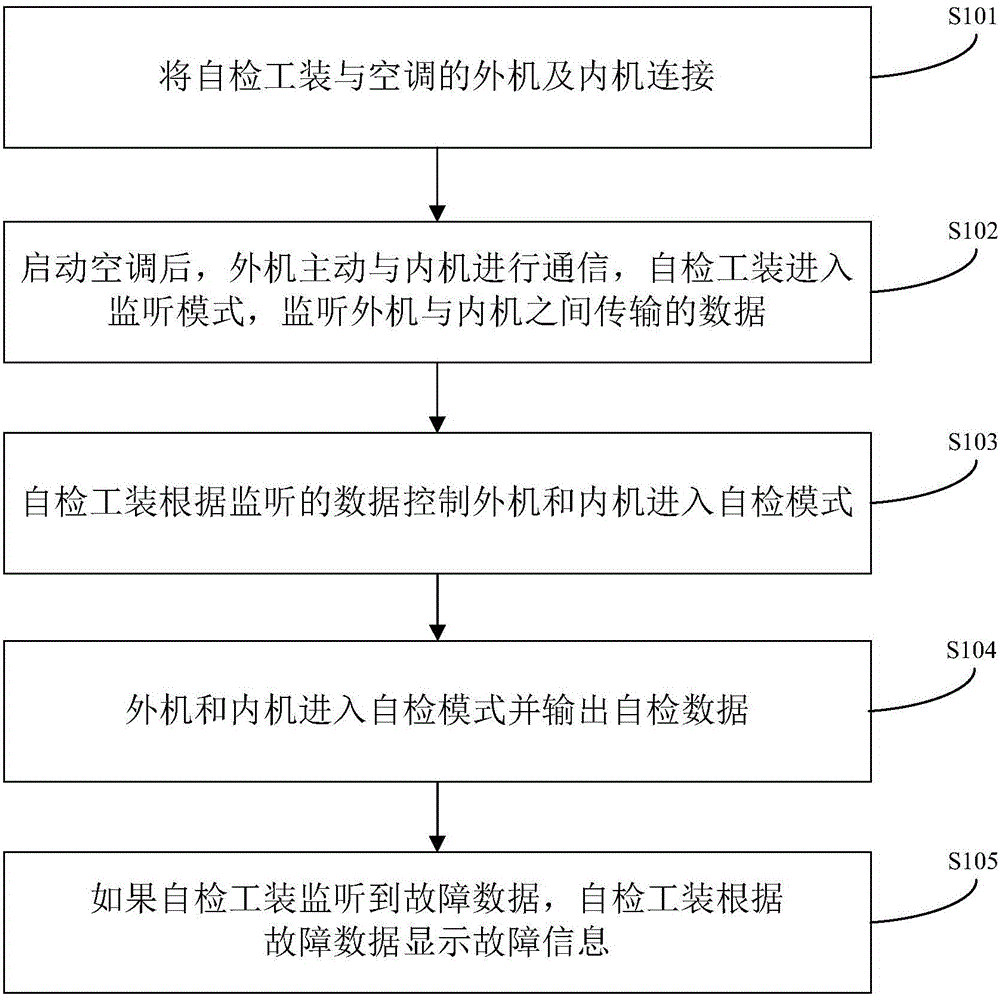

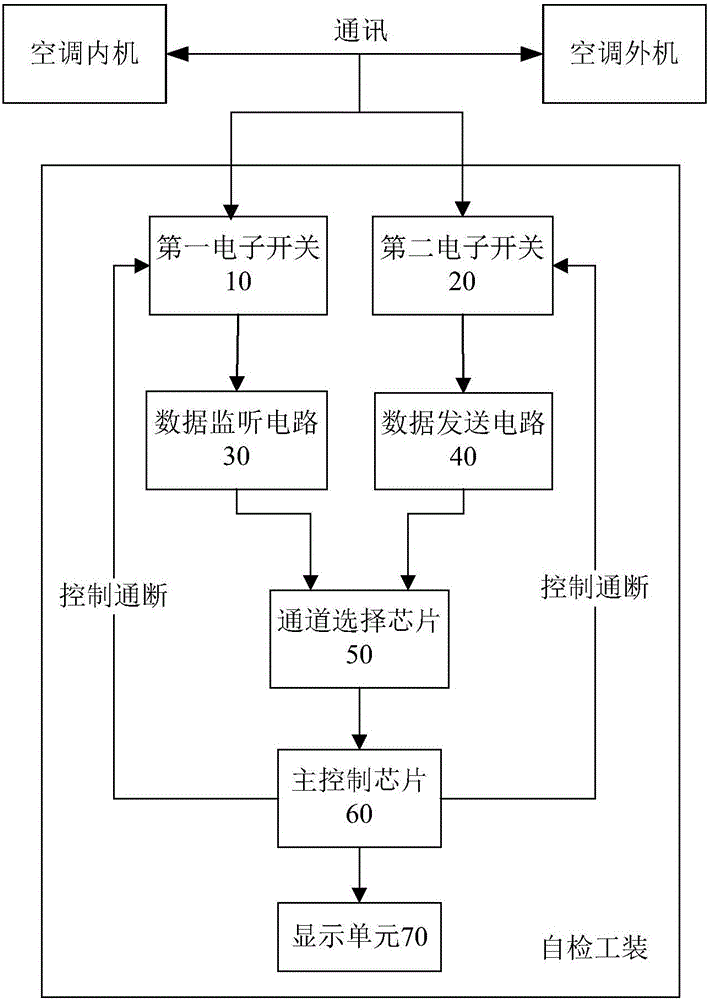

[0024] An embodiment of the present invention provides an air conditioner fault self-diagnosis method, figure 1 It is a flow chart of the air-conditioning fault self-checking method of the embodiment of the present invention, as figure 1 As shown, the method includes:

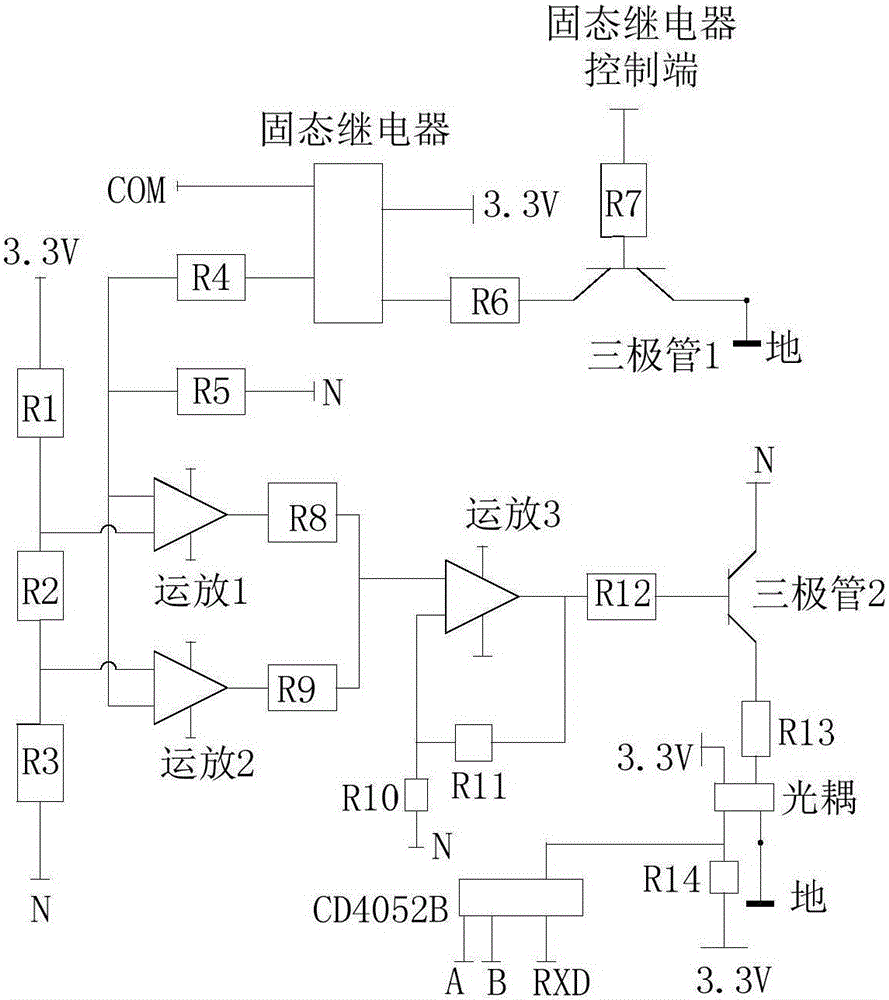

[0025] Step S101, connecting the self-inspection tool with the external unit and the internal unit of the air conditioner. Specifically, the self-inspection tooling can be connected to the internal and external units of the air conditioner through the L line (live line), the N line (neutral line), and the COM line (serial line) connected in parallel to the internal and external units.

[0026] Step S102, after starting the air conditioner, the outdoor unit actively communicates with the indoor unit, and the self-in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com