Efficient heat exchanging type cold storage bed system for magnetic refrigerator

A magnetic refrigerator and heat exchange technology, applied in the field of cold storage bed system, can solve the problems of affecting refrigeration effect and refrigeration efficiency, waste of low-temperature heat exchange medium, affecting refrigeration effect, etc., so as to improve refrigeration effect, prevent mutual heat exchange, Responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

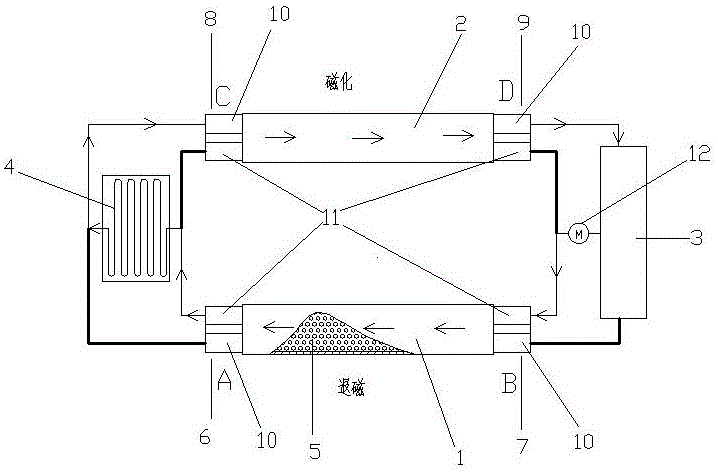

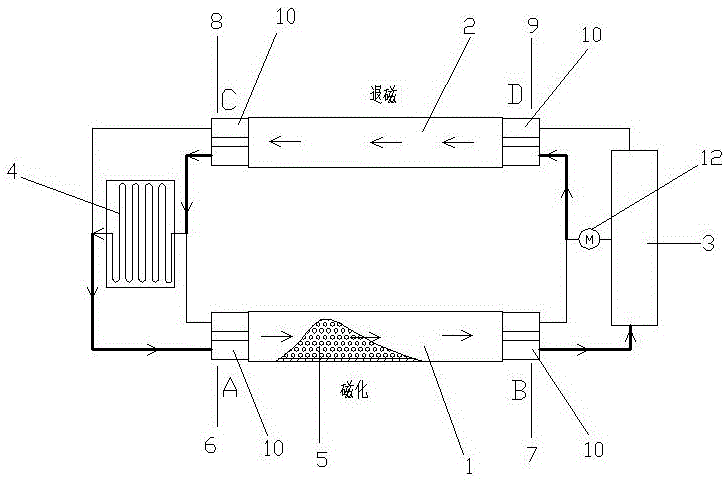

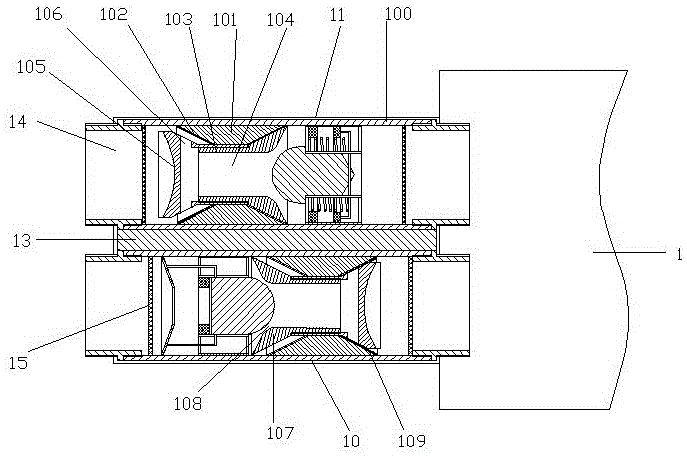

[0029] Such as figure 1 and figure 2 A high-efficiency heat-exchanging cold-storage bed system for a magnetic refrigerator is shown, including a cold-storage bed I1, a cold-storage bed II2, a heat-exchanging water tank 3, and a heat exchanger 4. Both the cold-storage bed I and the cold-storage bed II are filled with porous magnetic Working medium 5, the outer sides of cold storage bed I and cold storage bed II are provided with a magnetic field for magnetization and demagnetization of the magnetic working medium, and the two ends of cold storage bed I are respectively provided with valve group A6 and valve group B7, and the two ends of cold storage bed II are respectively provided with There are valve group C8 and valve group D9, such as figure 2 As shown, valve group A, valve group B, valve group C, and valve group D all include a one-way magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com