A method for determining the kinetic curve of carbide isothermal precipitation

A kinetic and carbide technology, used in the preparation of test samples, the use of stable tension/pressure to test the strength of materials, and the measurement device, etc., which can solve the problem of large sample errors, limited observation range of TEM analysis methods, and long time consuming. It can solve the problems of difficult quantification and insignificant changes, avoid the defects of uniformity of precipitates, and achieve the effect of simple and effective operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

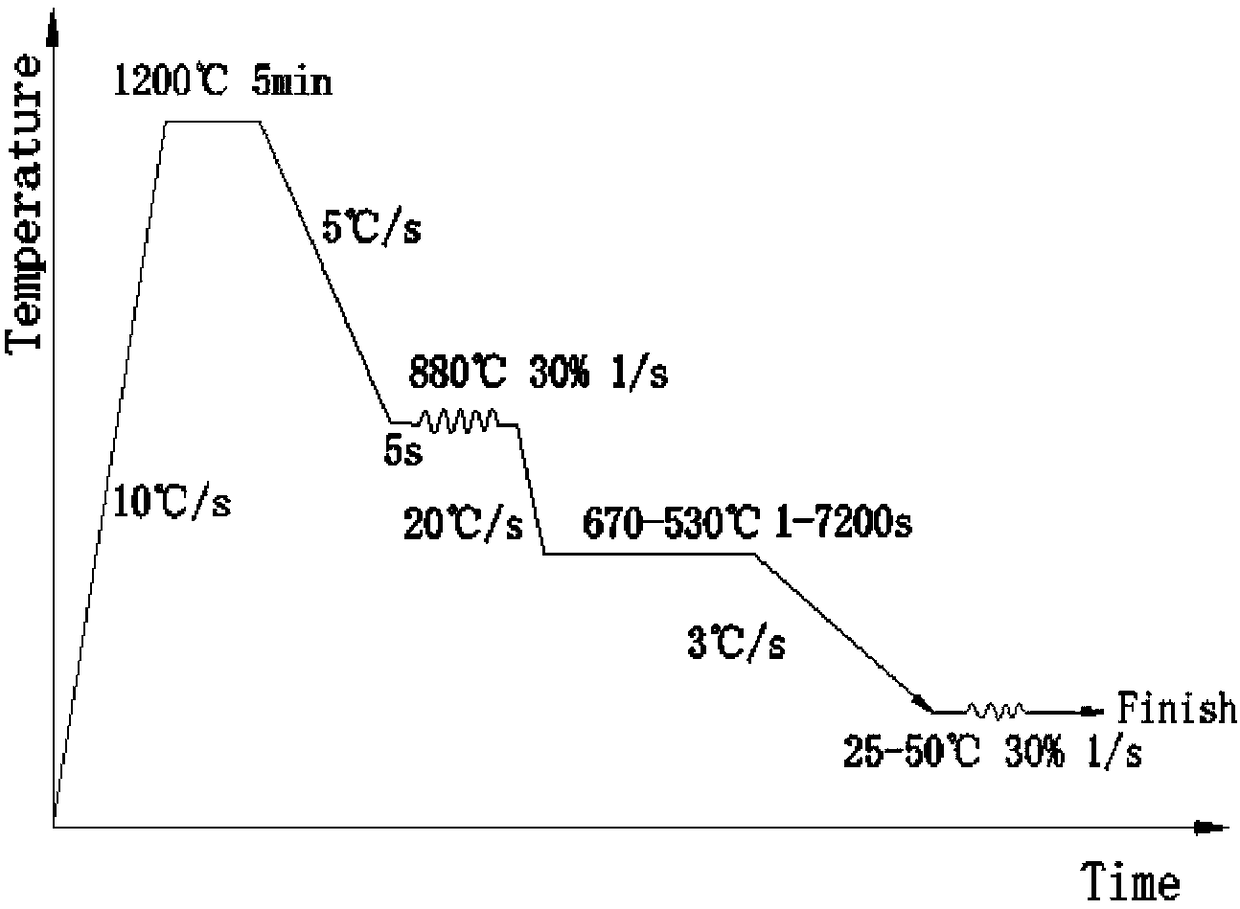

[0042] In order to better understand the present invention, the present invention will be further described below in conjunction with the examples and drawings, but it should be noted that the examples are not intended to limit the protection scope of the present invention.

[0043] This implementation is carried out on the general module of the Gleeble thermal simulation testing machine. The material of the selected test piece is Ti microalloy steel. 1.0-1.8wt%, Cr 0.10-0.30wt%, Ti 0.08-0.14wt%, P<0.015wt%, S<0.010wt%, and the rest are Fe and unavoidable impurities.

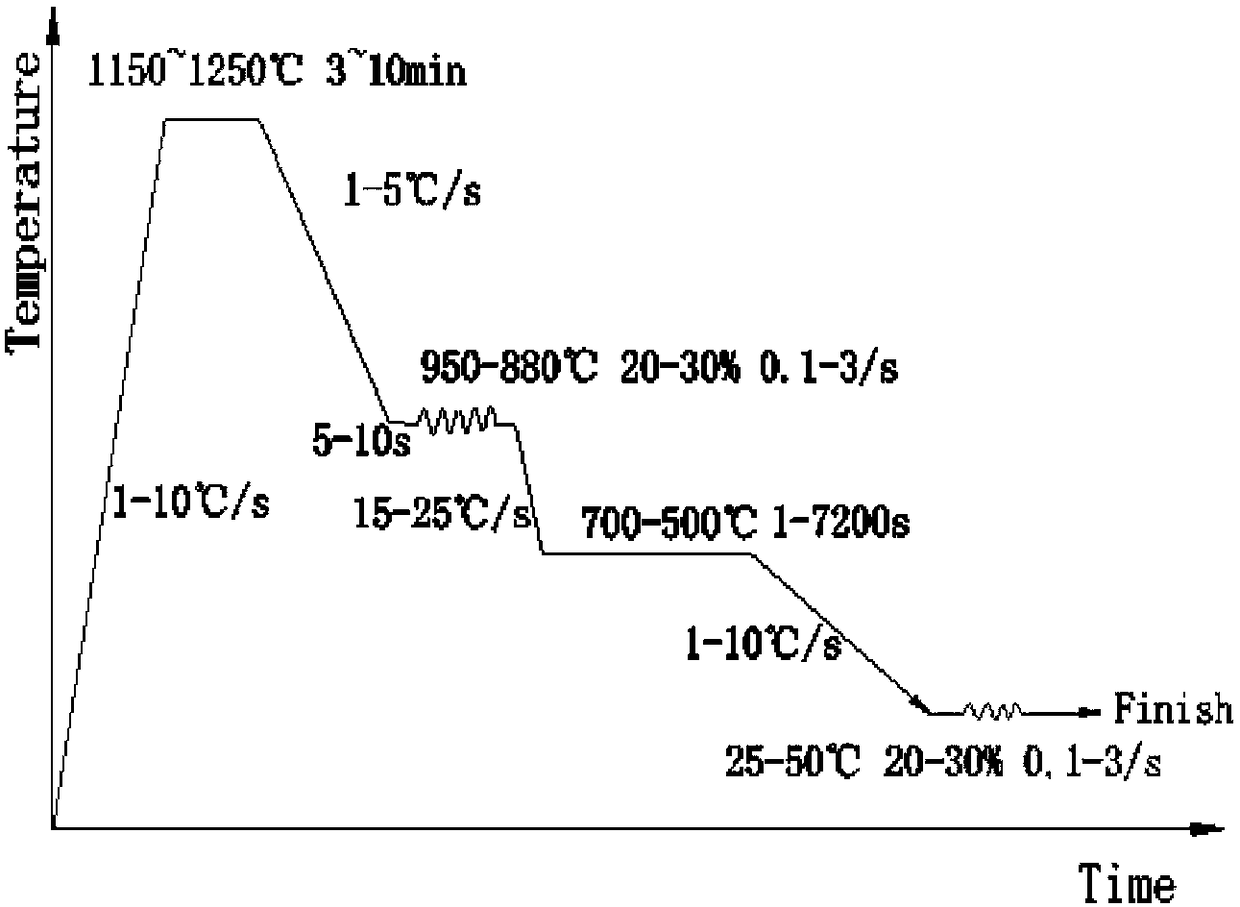

[0044] A method for determining a carbide isothermal precipitation kinetics curve, comprising the following steps:

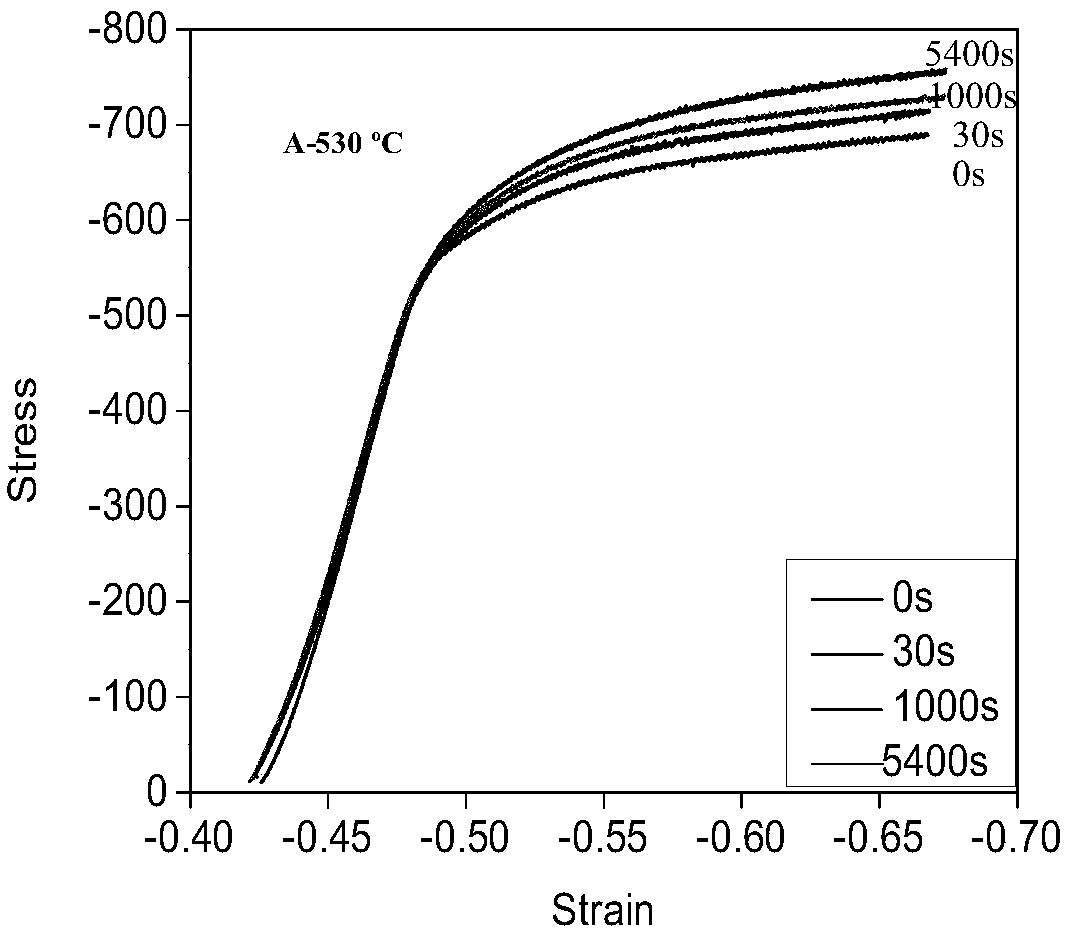

[0045] 1) Obtain the compressive yield stress value of the test piece at the set isothermal temperature and isothermal time through the thermal simulation testing machine;

[0046] 2) According to the strength increment Δσ of each compressive yield stress value relative to the lowest compressive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com