One-step wet process black silicon preparation and surface treatment method

A technology of surface treatment and black silicon, which is applied in the field of solar cells, can solve problems affecting direct industrial application, increased leakage, and decreased open-circuit voltage of solar cells, so as to solve the bottleneck of mass industrialization, low battery leakage rate, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Wet black silicon preparation and surface treatment method comprises the following steps:

[0058] (1) De-damage layer: Select a P-type polysilicon wafer (boron-doped, 1-3Qcm, 156X156mm square, thickness 180μm). Since the polysilicon wafer is cut with a diamond wire saw, it is necessary to perform alkali etching on the silicon wafer to remove damage layer;

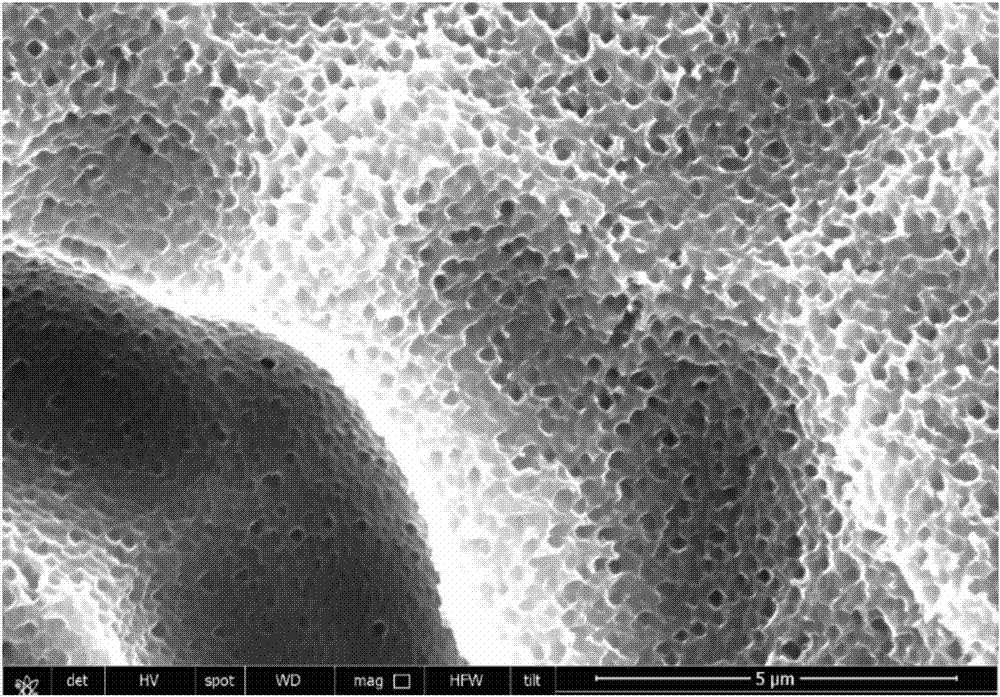

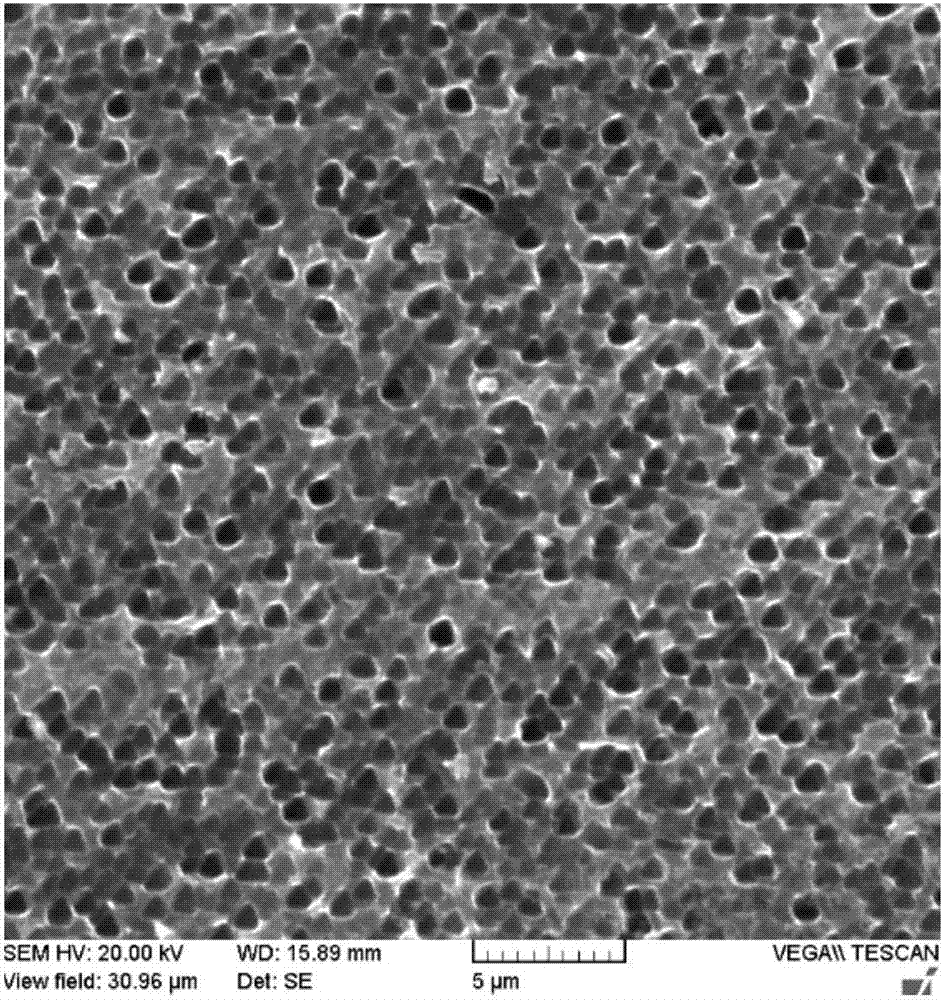

[0059] (2) Preparation of black silicon: Rinse the product wafer of step (1) with deionized water; after blowing dry, put it into the corrosion solution and react for 200 seconds at room temperature to prepare black silicon; wherein, the corrosion solution is metal ion-containing Mixed aqueous solution of concentrated hydrofluoric acid, oxidant and polymer; metal ions are derived from HAuCl 4 and AgNO 3 The combination of HAuCl4 and AgNO3 are electronic grade products, the weight ratio of HAuCl4 and AgNO3 is 1:6, the total content of HAuCl4 and AgNO3 in the solution is 0.01mol / L; the oxidant is hydrogen peroxide; ...

Embodiment 2

[0065] Wet black silicon preparation and surface treatment method comprises the following steps:

[0066] (1) De-damage layer: Select a P-type polysilicon wafer (boron-doped, 1-3Qcm, 156X156mm square, thickness 180μm). Since the polysilicon wafer is cut with a diamond wire saw, it is necessary to perform alkali etching on the silicon wafer to remove damage layer;

[0067] (2) Preparation of black silicon: Rinse the product wafer of step (1) with deionized water; after blowing dry, put it into the corrosion solution and react for 200 seconds at room temperature to prepare black silicon; wherein, the corrosion solution is metal ion-containing Mixed aqueous solution of concentrated hydrofluoric acid, oxidant and polymer; metal ions are derived from HAuCl 4 and AgNO 3 The combination of HAuCl4 and AgNO3 are electronic grade products, the weight ratio of HAuCl4 and AgNO3 is 1:5, the total content of HAuCl4 and AgNO3 in the solution is 0.007mol / L; the oxidant is hydrogen peroxide;...

Embodiment 3

[0073] Wet black silicon preparation and surface treatment method comprises the following steps:

[0074] (1) De-damage layer: Select a P-type polysilicon wafer (boron-doped, 1-3Qcm, 156X156mm square, thickness 180μm). Since the polysilicon wafer is cut with a diamond wire saw, it is necessary to perform alkali etching on the silicon wafer to remove damage layer;

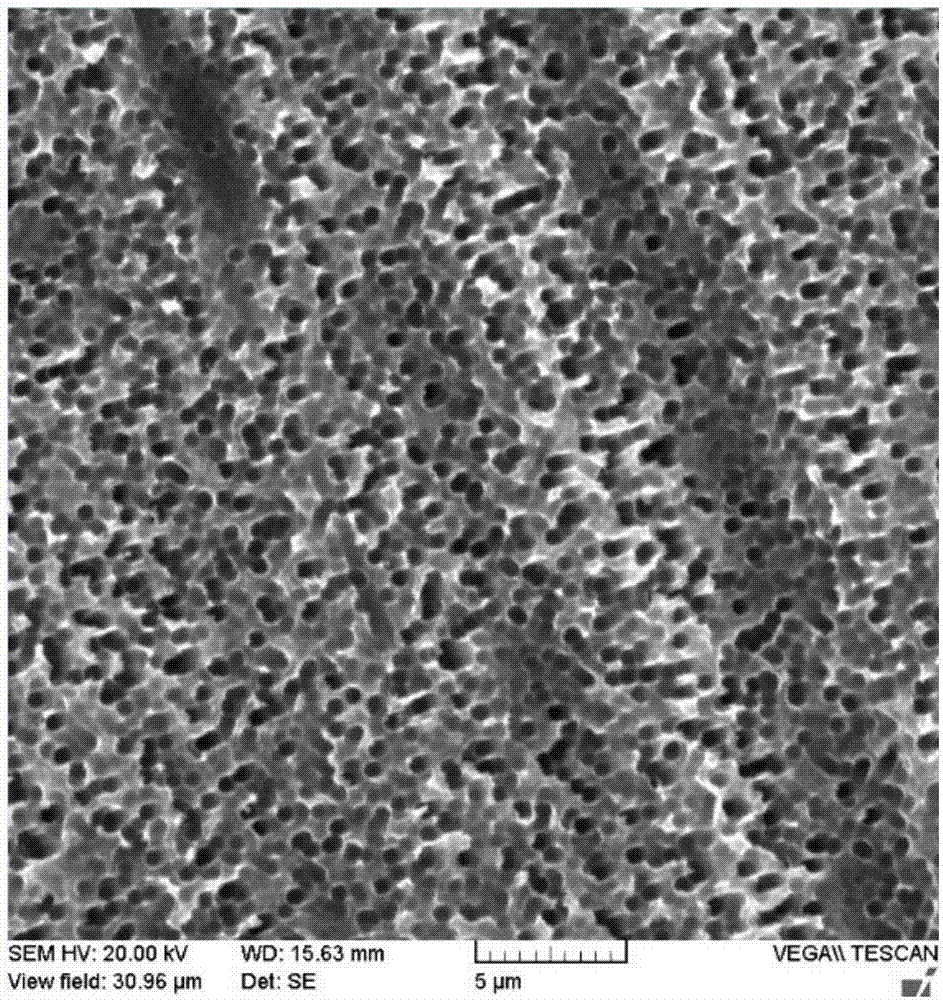

[0075] (2) Preparation of black silicon: Rinse the product wafer of step (1) with deionized water; after drying, put it into the corrosion solution and react for 300 seconds at 10°C to prepare black silicon; wherein, the corrosion solution contains metal ions The mixed aqueous solution of concentrated hydrofluoric acid, oxidant and high molecular polymer; the metal ion is derived from the combination of potassium chloroplatinate and palladium acetate, both of which are electronic grade products, potassium chloroplatinate and palladium acetate The weight ratio is 1:5, and the total content of potassium chloroplatina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com