LED epitaxial wafer with current blocking layer and manufacturing method thereof

A technology of LED epitaxial wafer and current blocking layer, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of LED failure and no current around the electrode, and achieve the effect of preventing excessive concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] see Figure 1-8 , the present invention at first provides a kind of manufacturing method of the LED epitaxial wafer with current blocking layer, specifically comprises the following steps:

[0027] see figure 1 , providing a substrate 1, the substrate 1 is a sapphire substrate;

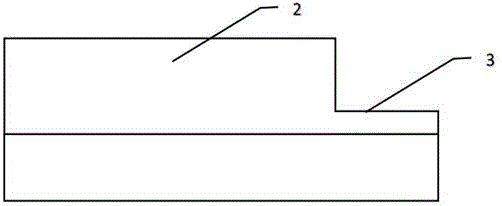

[0028] see figure 2 , growing a GaN epitaxial layer 2 on the substrate 1: sequentially growing a silicon-doped N-type GaN layer, a multi-quantum well light-emitting layer, and a magnesium-doped P-type GaN layer on the substrate 1; and then etching by dry etching Out of the first electrode placement area 3, the placement area is stepped;

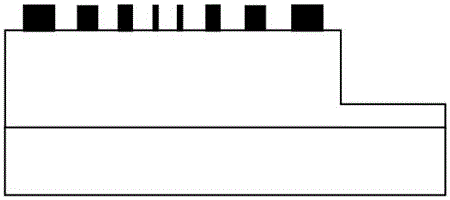

[0029] see image 3 , forming a photoresist layer 4 in the unetched region of the GaN epitaxial layer 2;

[0030] see Figure 4 , etch the photoresist layer 4 to form a series of concentric rings; fill the concentric rings with ITO to form a conductive ring 5, the center of the conductive ring 5 is connected to the unetched region of the GaN epitaxial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com