Temperature-control component as well as battery module and battery box

A technology of temperature control components and battery modules, which is applied to battery components, secondary batteries, circuits, etc., can solve the problems that the battery box does not have a heating function and the energy supply efficiency is not high, so as to improve the energy supply efficiency and lifespan The effect of prolonging and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

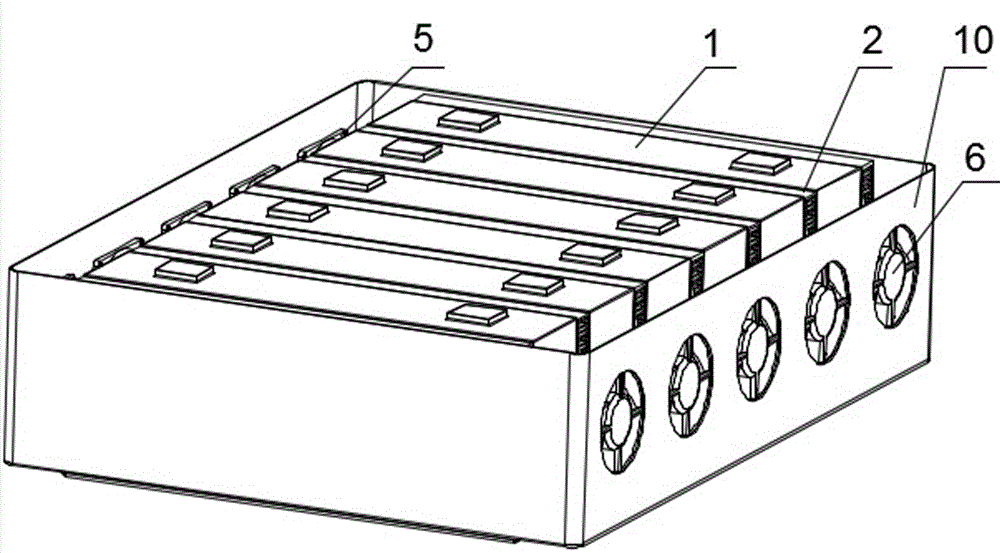

[0027] A specific embodiment of the battery box of the present invention, such as figure 1 As shown, it includes an upper cover (omitted), a box body 10 and a battery module set in the box body 10 . The box body 10 has four side walls, the front, the rear, the left, and the right. The air intake fans 5 are evenly distributed on the front side walls of the battery box, and the exhaust fans 6 are evenly distributed on the rear side walls of the battery box. The positions and quantities of the air intake fans 6 and the exhaust fans 5 are is corresponding. The corresponding fan can accelerate the circulation of cold air during heat dissipation, so that the cold air can act on the battery module more quickly and evenly.

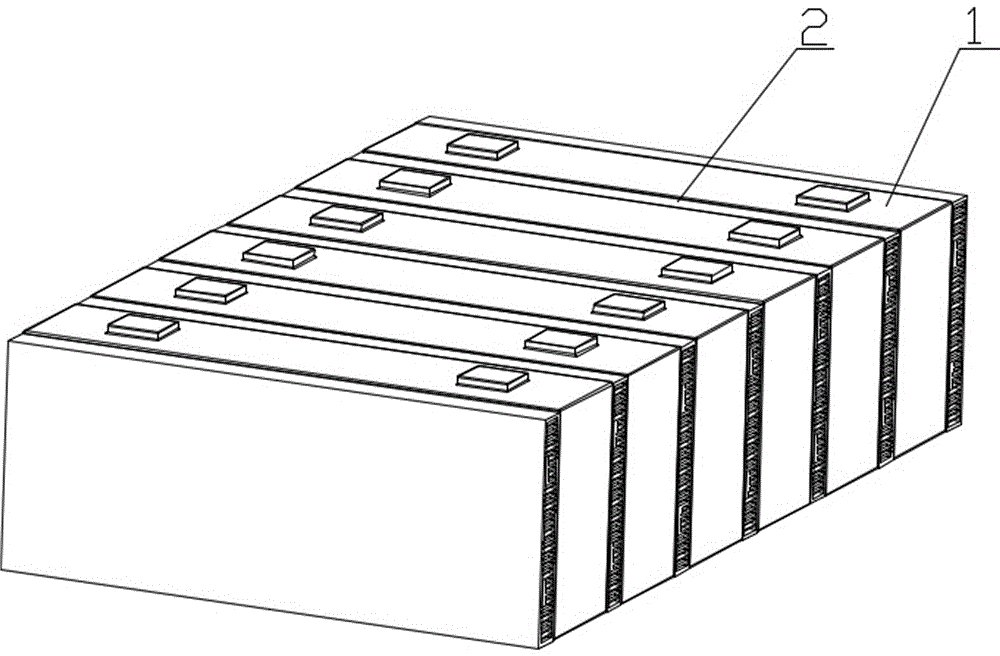

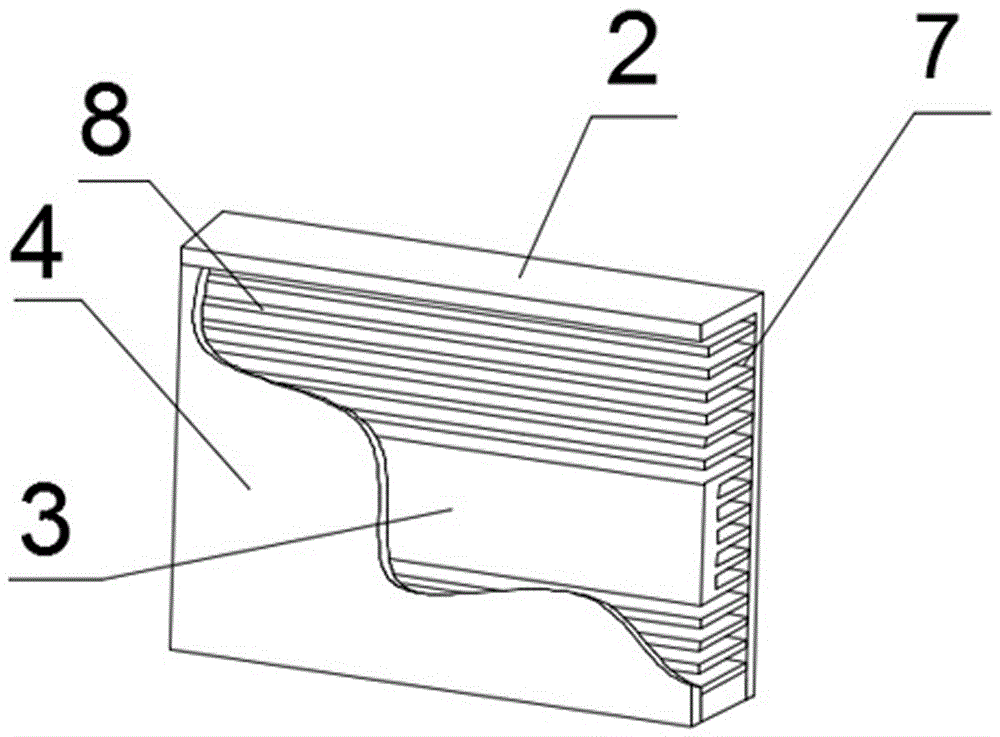

[0028] The structure of the battery module in the battery box is as follows: figure 2 and Figure 4 As shown, it includes a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com