A high specific energy density lithium-ion battery

A lithium-ion battery, energy density technology, applied in the direction of battery electrodes, secondary batteries, battery components, etc., can solve the problem of low energy density, achieve high conductivity, improve conductivity and adhesion, and power performance Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

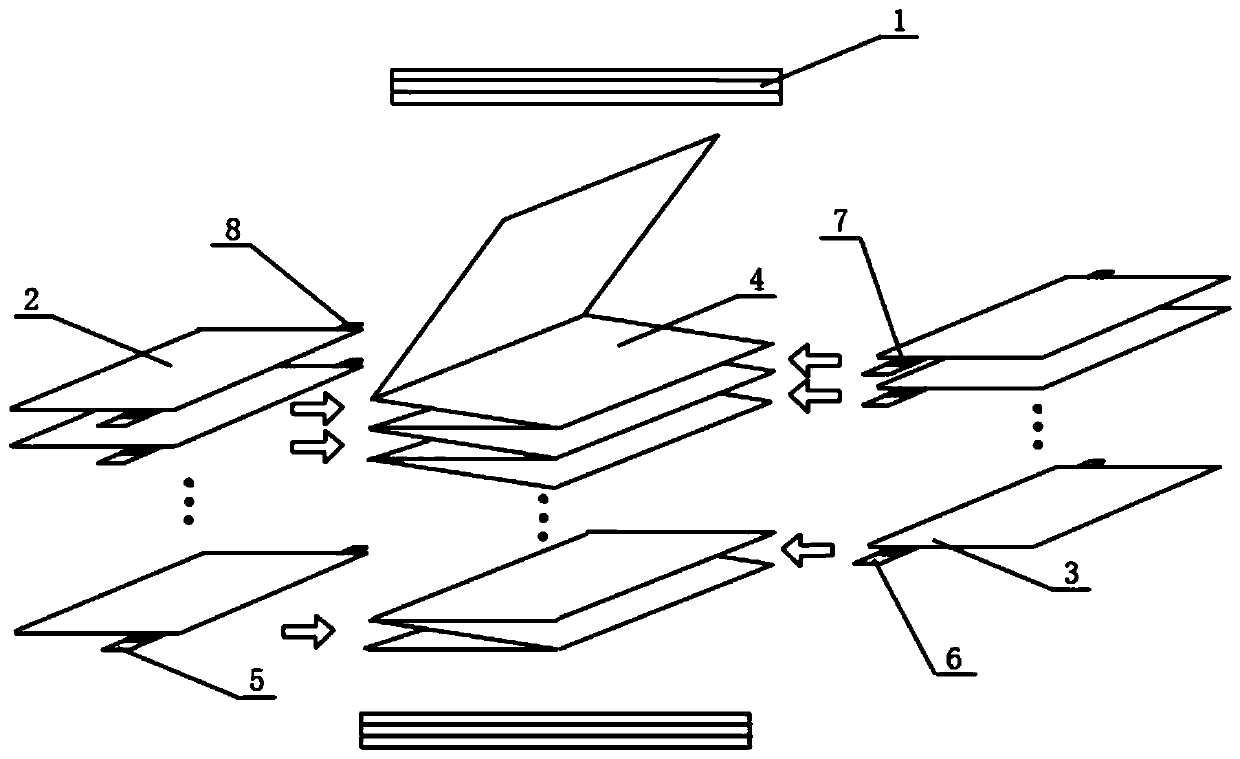

[0029] Such as figure 1 As shown, the positive electrode sheet 2 and the negative electrode sheet 3 of the lithium-ion battery interleavedly stacked with the composite aluminum-plastic packaging film 1, and the separator 4 sandwiched between the positive electrode sheet 2 and the negative electrode sheet 3 are packaged, and the commercial electrolyte is injected according to the conventional method. One end of each positive pole piece 2 fixes a positive pole tab 5 through an output tab foil 7, and the other end fixes a connection tab foil 8; one end of each negative pole piece 3 fixes a negative pole tab 6 through an output tab foil 7, The other end is fixed with a connecting tab foil 8; the tops of all positive tabs 5 and negative tabs 6 are aligned, all the connecting tab foils 8 fixed on the positive electrode sheet 2 are connected together, and all the connecting tab foils 8 fixed on the negative electrode sheet 3 are connected together. The current collector of the posit...

Embodiment 2

[0033] Such as figure 1 As shown, the positive electrode sheet 2 and the negative electrode sheet 3 of the lithium-ion battery interleavedly stacked with the composite aluminum-plastic packaging film 1, and the separator 4 sandwiched between the positive electrode sheet 2 and the negative electrode sheet 3 are packaged, and the commercial electrolyte is injected according to the conventional method. One end of each positive pole piece 2 fixes a positive pole tab 5 through an output tab foil 7, and the other end fixes a connection tab foil 8; one end of each negative pole piece 3 fixes a negative pole tab 6 through an output tab foil 7, The other end is fixed with a connecting tab foil 8; the tops of all positive tabs 5 and negative tabs 6 are aligned, all the connecting tab foils 8 fixed on the positive electrode sheet 2 are connected together, and all the connecting tab foils 8 fixed on the negative electrode sheet 3 are connected together. The current collector of the posit...

Embodiment 3

[0037] Such as figure 1As shown, the positive electrode sheet 2 and the negative electrode sheet 3 of the lithium-ion battery interleavedly stacked with the composite aluminum-plastic packaging film 1, and the separator 4 sandwiched between the positive electrode sheet 2 and the negative electrode sheet 3 are packaged, and the commercial electrolyte is injected according to the conventional method. One end of each positive pole piece 2 fixes a positive pole tab 5 through an output tab foil 7, and the other end fixes a connection tab foil 8; one end of each negative pole piece 3 fixes a negative pole tab 6 through an output tab foil 7, The other end is fixed with a connecting tab foil 8; the tops of all positive tabs 5 and negative tabs 6 are aligned, all the connecting tab foils 8 fixed on the positive electrode sheet 2 are connected together, and all the connecting tab foils 8 fixed on the negative electrode sheet 3 are connected together. The current collector of the positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com