co 3 o 4 /co 2 P coaxial heterostructure material and its preparation method and application

A heterostructure, coaxial technology, applied in nanotechnology, nanotechnology, hybrid capacitor electrodes, etc. for materials and surface science, can solve the problem of low energy density of MSCs, insufficient to meet the needs of microelectronic devices, and limit the development of MSCs To achieve good electron conductivity, achieve energy density and rate performance, high capacity and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

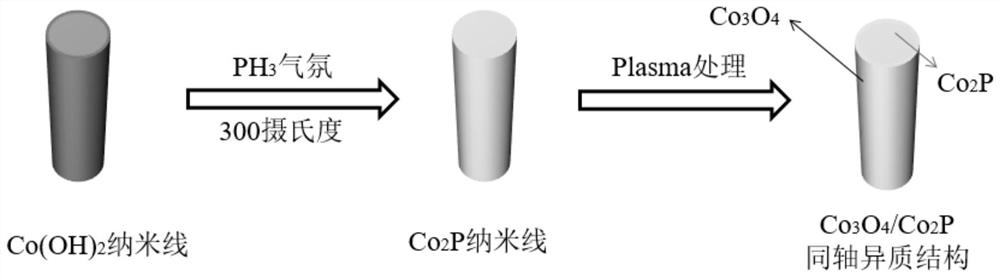

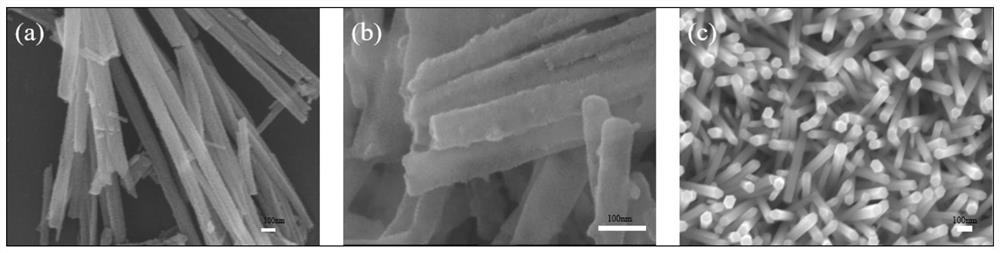

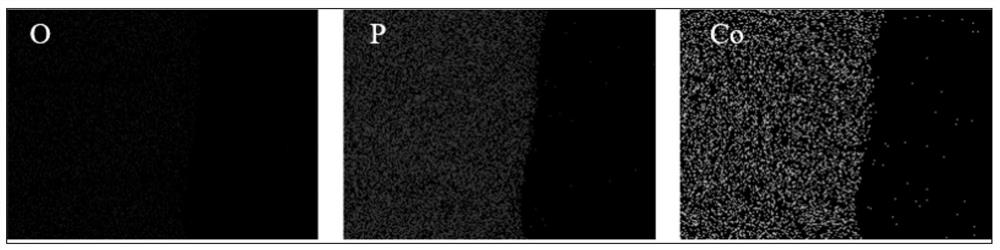

[0024] A kind of Co 3 o 4 / Co 2 The preparation process of P coaxial heterostructure micro-supercapacitor electrode materials, such as figure 1 , including the following steps:

[0025] 1) Using a hydrothermal method to prepare cobalt hydroxide nanowires:

[0026] 1a) Foam nickel cleaning: first cut the foam nickel, pass through hydrochloric acid, deionized water, acetone, and ethanol in sequence for 15 minutes, and dry it in a 60°C oven for 12 hours, take out and weigh the dry nickel foam;

[0027] 1b) Add 2mmol of cobalt chloride hexahydrate, 1mmol of ammonium fluoride, and 4mmol of urea into 70mL of deionized water, and stir for 15 minutes to dissolve them evenly;

[0028] 1c) Add the solution into a polytetrafluoroethylene reactor, put in the foamed nickel that has been weighed after cleaning, and heat it in water at 120°C for 8-12 hours. After cooling, wash it centrifugally with deionized water and ethanol, and put it into Oven drying obtains the nickel foam that is ...

Embodiment 2

[0037] A kind of Co 3 o 4 / Co 2 The preparation process of P coaxial heterostructure micro-supercapacitor electrode material comprises the following steps:

[0038] 1) Using a hydrothermal method to prepare cobalt hydroxide nanowires:

[0039] 1a) Foam nickel cleaning: first cut the foam nickel, pass through hydrochloric acid, deionized water, acetone, and ethanol in sequence for 15 minutes, and dry it in a 60°C oven for 12 hours, take out and weigh the dry nickel foam;

[0040] 1b) Add 5 mmol of cobalt chloride hexahydrate, 2.5 mmol of ammonium fluoride, and 10 mmol of urea into 70 mL of deionized water, and stir for 20 minutes to dissolve them evenly;

[0041] 1c) Add the solution into a polytetrafluoroethylene reactor, put in the foamed nickel that has been weighed after cleaning, and heat it in water at 120°C for 8-12 hours. After cooling, wash it centrifugally with deionized water and ethanol, and put it into Oven drying obtains the nickel foam that is loaded with cob...

Embodiment 3

[0049] A kind of Co 3 o 4 / Co 2 The preparation process of P coaxial heterostructure micro-supercapacitor electrode material comprises the following steps:

[0050] 1) Using a hydrothermal method to prepare cobalt hydroxide nanowires:

[0051] 1a) Cleaning of foamed nickel: First, cut out the foamed nickel, pass through hydrochloric acid, deionized water, acetone, and ethanol in sequence for 15 minutes, and dry it in an oven at 60°C for 12 hours, then take out and weigh the mass of the dried nickel foam.

[0052] 1b) Add 10 mmol of cobalt chloride hexahydrate, 5 mmol of ammonium fluoride, and 20 mmol of urea into 70 mL of deionized water, and stir for 30 minutes to dissolve them evenly.

[0053] 1c) Add the solution into a polytetrafluoroethylene reactor, put in the foamed nickel that has been weighed after cleaning, and heat it in water at 120°C for 8-12 hours. After cooling, wash it centrifugally with deionized water and ethanol, and put it into Oven drying to obtain nic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com