Aqueous lithium ion battery li y ti 2-x m x (po 4 ) 3 /c negative electrode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as short cycle life, achieve improved cycle performance, increase specific energy density, and achieve the effect of working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

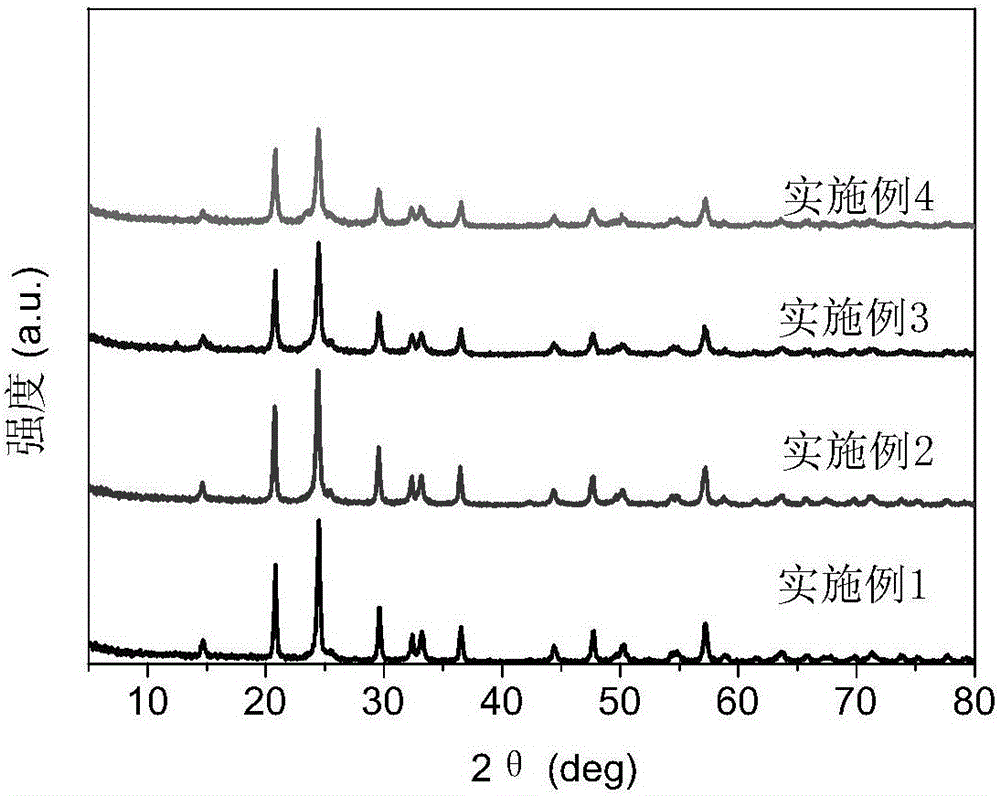

[0034] Dissolve 0.1g of phenolic resin, 3.3494g of n-butyl titanate and 0.5168g of lithium acetate in 30ml of ethanol (referred to as solution a), and dissolve 1.7581g of phosphoric acid in another 30ml of ethanol (referred to as solution b). Slowly drop solution b into solution a under stirring, stir and reflux at 55° for 3 hours, evaporate the solvent to dryness, and obtain a precursor. The precursors were placed in a tube furnace under Ar / H 2 Under a protective atmosphere, the temperature was raised to 700°C at a heating rate of 5°C / min, and sintered for 5 hours to obtain LiTi 2 (PO 4 ) 3 / C target material. Its XRD such as figure 1 shown. It can be seen from the figure that the target material is pure phase LiTi 2 (PO 4 ) 3 , NASICON structure, space group R3c, rhombohedral.

[0035] The prepared LiTi 2 (PO 4 ) 3 / C Active material, conductive agent Super P and binder polytetrafluoroethylene (PTFE) are mixed uniformly in a certain mass ratio (80:10:10), rolled ...

Embodiment 2

[0037] Dissolve 0.3g of phenolic resin, 3.3494g of n-butyl titanate and 0.5168g of lithium acetate in 30ml of ethanol (referred to as solution a), and dissolve 1.7581g of phosphoric acid in another 30ml of ethanol (referred to as solution b). Slowly drop solution b into solution a under stirring, reflux and stir at 55° for 3 hours, then evaporate the solvent to dryness to obtain a precursor. The precursors were placed in a tube furnace under Ar / H 2 Under a protective atmosphere, the temperature was raised to 700°C at a heating rate of 5°C / min, and sintered for 5 hours to obtain LiTi 2 (PO 4 ) 3 / C target material. Its XRD such as figure 1 . It can be seen from the figure that the target material is pure phase LiTi 2 (PO 4 ) 3 , NASICON structure, space group R3c, rhombohedral.

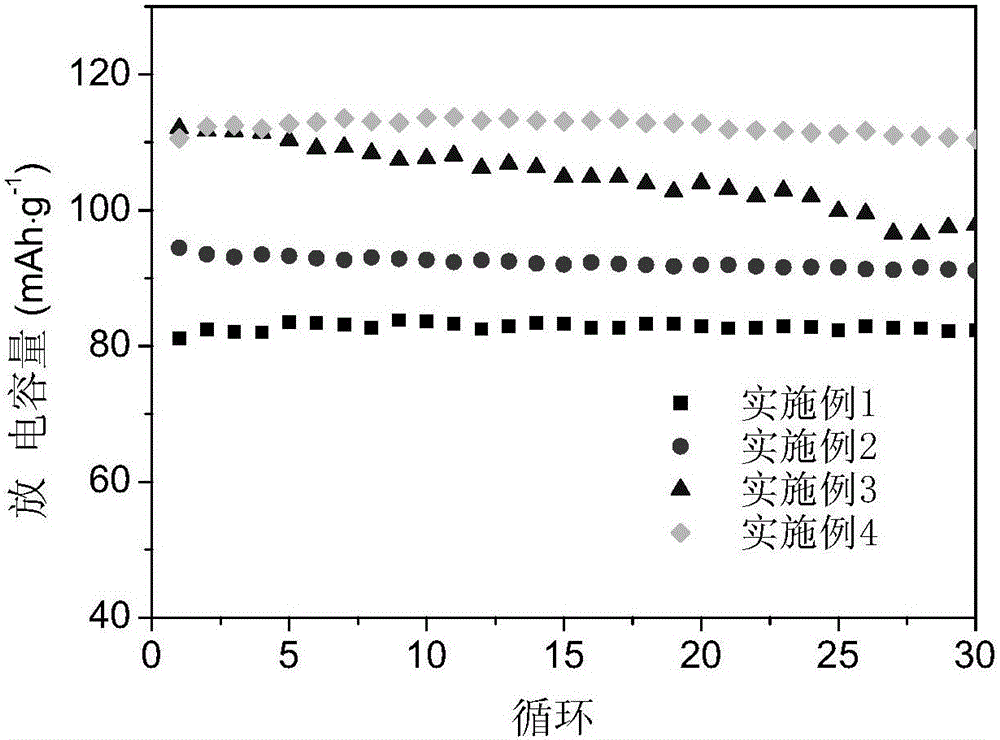

[0038] After preparing the pole piece and assembling the battery according to Example 1, the test was carried out. image 3 Recorded the capacity retention diagram of the battery for the firs...

Embodiment 3

[0040] Dissolve 0.5g of phenolic resin, 3.3494g of n-butyl titanate and 0.5168g of lithium acetate successively in 30ml of ethanol (referred to as solution a), and dissolve 1.7581g of phosphoric acid (purity>85%) in another 30ml of ethanol ( denoted as solution b). Slowly drop solution b into solution a under stirring, stir and reflux at 55° for 3 hours, evaporate the solvent to dryness, and obtain a precursor. The precursors were placed in a tube furnace under Ar / H 2 Under a protective atmosphere, the temperature was raised to 700°C at a heating rate of 5°C / min, and sintered for 4 hours to obtain LiTi 2 (PO 4 ) 3 / C target material. figure 1 Its XRD pattern. It can be seen from the figure that the target material is pure phase LiTi 2 (PO 4 ) 3 , NASICON structure, space group R3c, rhombohedral.

[0041] After preparing the pole piece and assembling the battery according to Example 1, the test was carried out. image 3 Recorded the capacity retention diagram of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com