A kind of preparation method of flexible positive electrode of lithium-sulfur battery

A lithium-sulfur battery, flexible technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of reduced relative content of active materials, unsatisfactory battery rate performance, and limited battery energy density, etc., to achieve high porosity, good mechanical Performance, the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

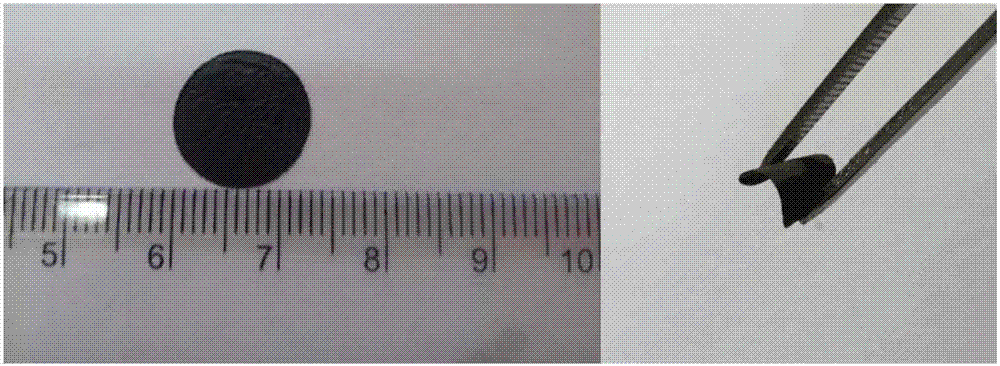

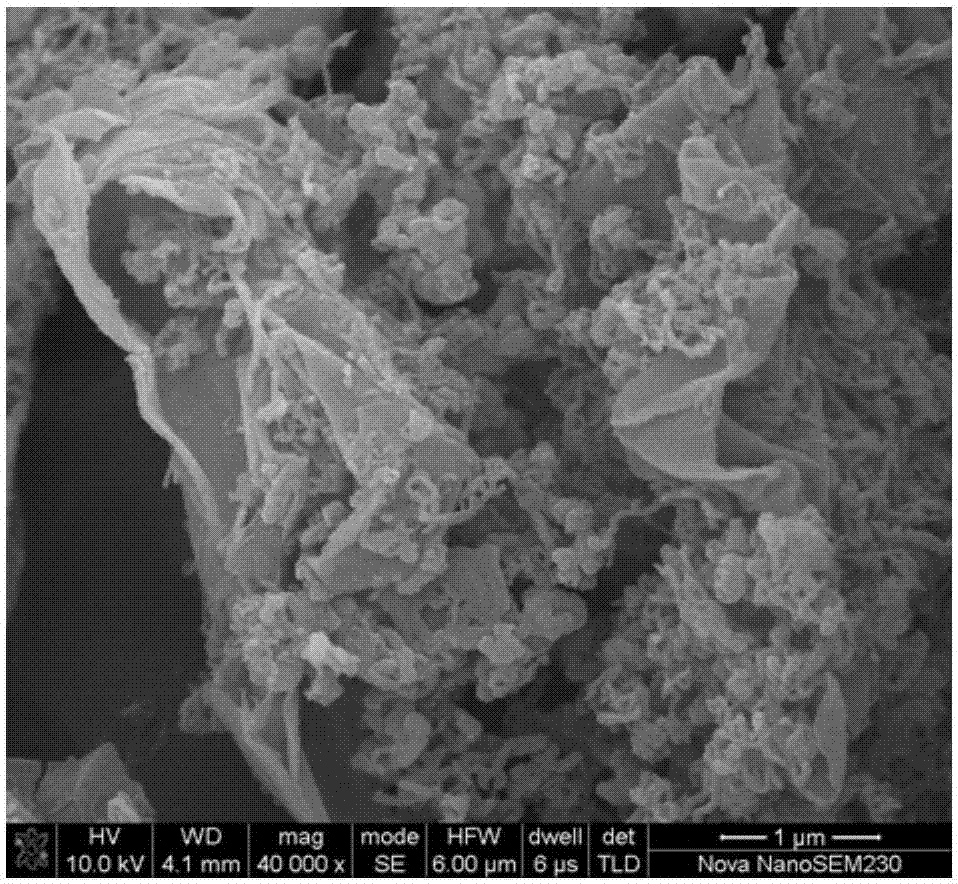

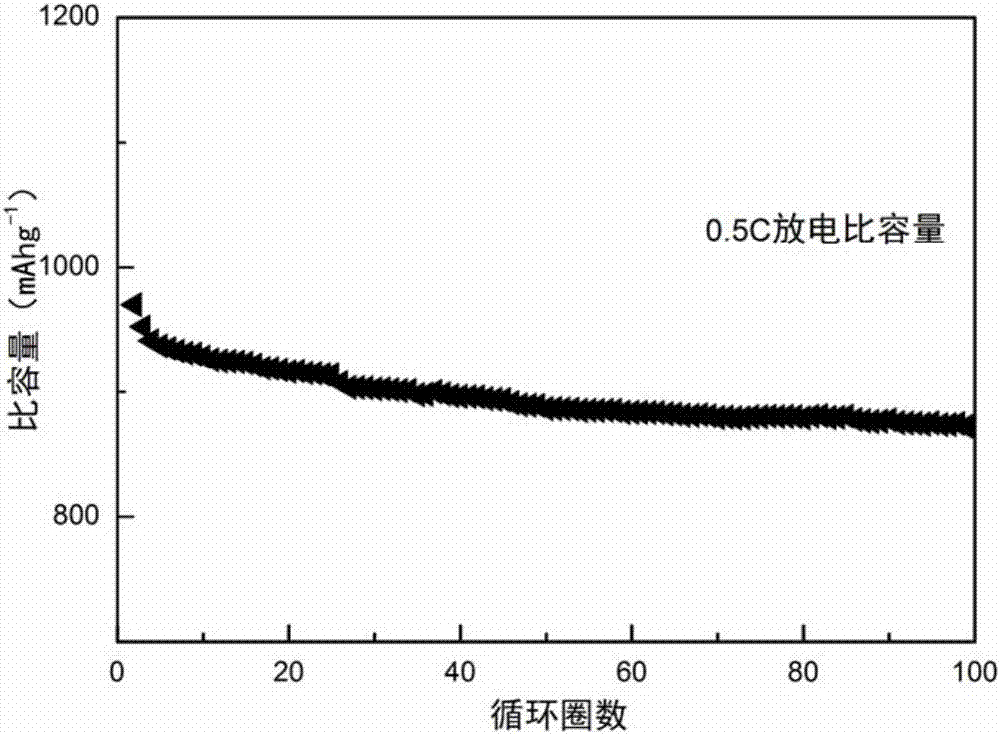

Embodiment 1

[0025]Get 7.3g of cetyltrimethylammonium bromide (CTAB) and 13.7g of ammonium persulfate (APS) and dissolve in the cooled 120mL hydrochloric acid solution (1mol / L), stir evenly under ice bath conditions for 40min, then slowly add 8.3 mL of pyrrole monomer was reacted at 0-5°C for 24 hours, the product was washed with deionized water and hydrochloric acid solution, and dried at 80°C to obtain polypyrrole fiber; take 2g of polypyrrole fiber and 6g of potassium hydroxide, and mix them uniformly in an inert atmosphere Under protection, the temperature was raised to 800°C at a heating rate of 5°C / min, and nitrogen-doped porous carbon fibers were obtained after holding for 3 hours; 0.5g of nitrogen-doped porous carbon fibers were uniformly mixed with 0.9g of elemental sulfur and 0.1g of elemental selenium by ball milling, and then Pour it into a closed stainless steel reaction kettle, raise the temperature to 260°C at a heating rate of 2°C / min, and heat it for 24 hours to obtain a ni...

Embodiment 2

[0036] Take 3.65g of cetyltrimethylammonium bromide (CTAB) and 6.85g of ammonium persulfate (APS) and dissolve them in a cooled 100mL hydrochloric acid solution (1mol / L), stir evenly under ice bath conditions for 40min, then slowly add 8.3 mL of pyrrole monomer was reacted at 0-5°C for 24 hours, the product was washed with deionized water and hydrochloric acid solution, and dried at 80°C to obtain polypyrrole fibers; take 1g of polypyrrole fibers and 3g of potassium hydroxide and mix them uniformly in an inert atmosphere Under protection, the temperature was raised to 1000°C at a heating rate of 5°C / min, and nitrogen-doped porous carbon fibers were obtained after holding for 3 hours; 0.5g of carbon fibers, 0.5g of elemental sulfur and 0.01g of elemental selenium were evenly mixed by ball milling, and then poured into a closed In a stainless steel reaction kettle, with a heating rate of 2°C / min, the temperature was raised to 260°C for heat treatment, and then kept for 24 hours t...

Embodiment 3

[0039] Get 7.3g of cetyltrimethylammonium bromide (CTAB) and 13.7g of ammonium persulfate (APS) and dissolve in the cooled 120mL hydrochloric acid solution (1mol / L), stir evenly under ice bath conditions for 40min, then slowly add 8.3 mL of pyrrole monomer was reacted at 0-5°C for 24 hours, the product was washed with deionized water and hydrochloric acid solution, and dried at 80°C to obtain polypyrrole fibers; take 1g of polypyrrole fibers and 3g of potassium hydroxide and mix them uniformly in an inert atmosphere Under protection, the temperature was raised to 1200°C at a heating rate of 5°C / min, and nitrogen-doped porous carbon fibers were obtained after holding for 2 hours; 0.5g of carbon fibers, 0.8g of elemental sulfur and 0.024g of elemental selenium were evenly ball-milled, and then poured into a closed In a stainless steel reaction kettle, with a heating rate of 2°C / min, the temperature was raised to 260°C for heat treatment, and then kept for 24 hours to obtain a nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com