A class of layered perovskite nano-oxide electrode materials for supercapacitors

A technology of supercapacitors and nano-oxides, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of low specific capacitance and low specific energy density of supercapacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

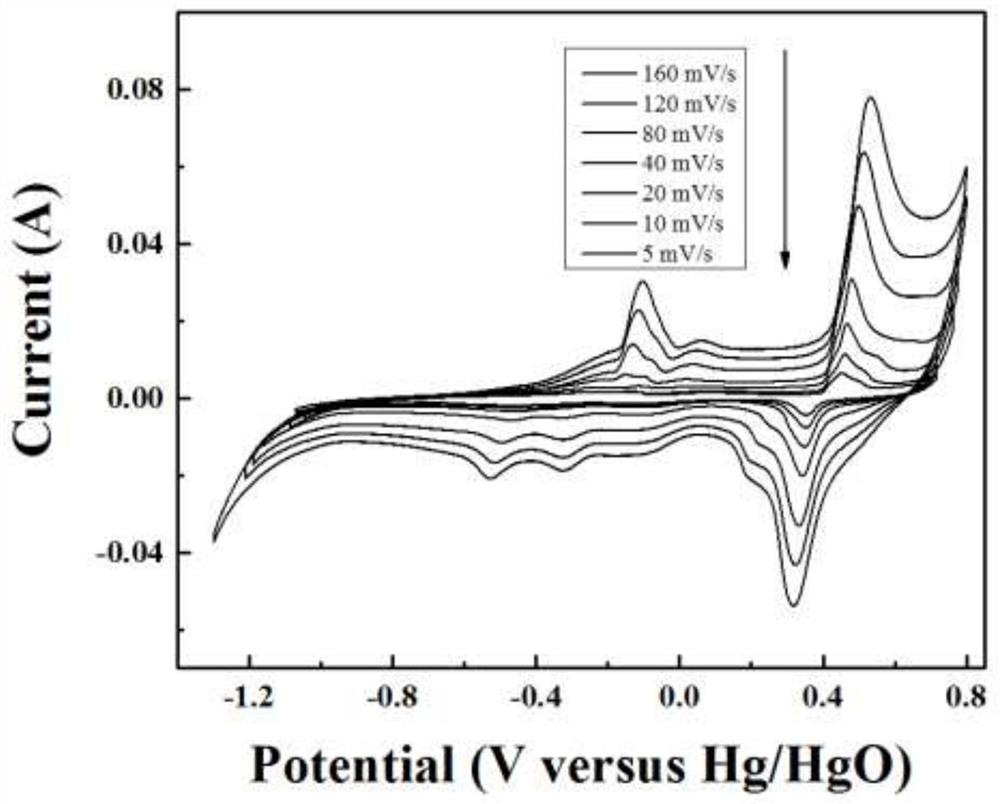

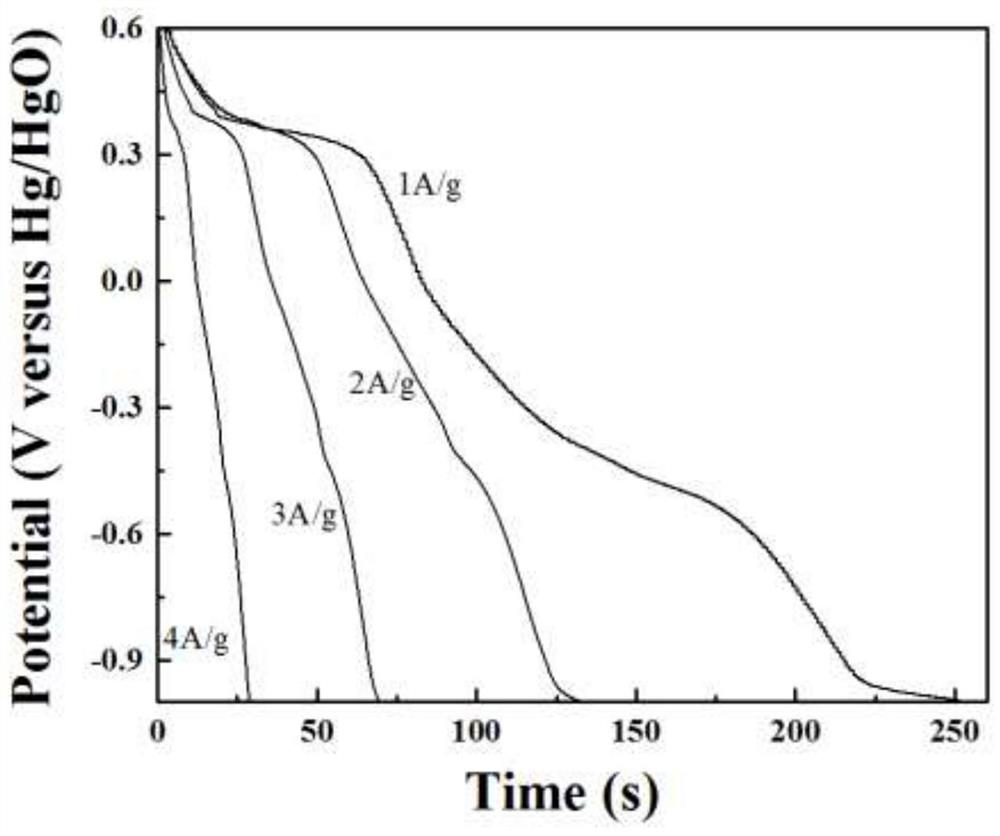

[0027] Embodiment 1 (La 0.85 Sr 1.15 )MnO 4 supercapacitor material

[0028] Prepared by sol-gel method (La 0.85 Sr 1.15 )MnO 4 . The process steps are as follows: use nitrates of various metal ions as raw materials to prepare La(NO 3 ) 3 , Sr(NO 3 ) 2 and Mn(NO 3 ) 2 aqueous solution, first pipette the La(NO 3 ) 3 Solution 17mL, Sr(NO 3 ) 2 Solution 23mL, Mn(NO 3 ) 2 Put 20mL of the solution into a 250mL beaker, and add 0.12mol of citric acid to the beaker. Then add methanol to the beaker to dilute the solution by 100mL, stir until completely dissolved and then add 6mL of ethylene glycol. Then, the solution was moved into a water bath at 88°C, heated with stirring, and a uniform and transparent sol was formed for 55 minutes, and the sol was transferred into an oven at 180°C for heat treatment for 20 hours to form a xerogel precursor. Grind the dry gel precursor and transfer it to a tube furnace. In an oxygen atmosphere, first keep it at 200°C for 30 minutes...

Embodiment 2

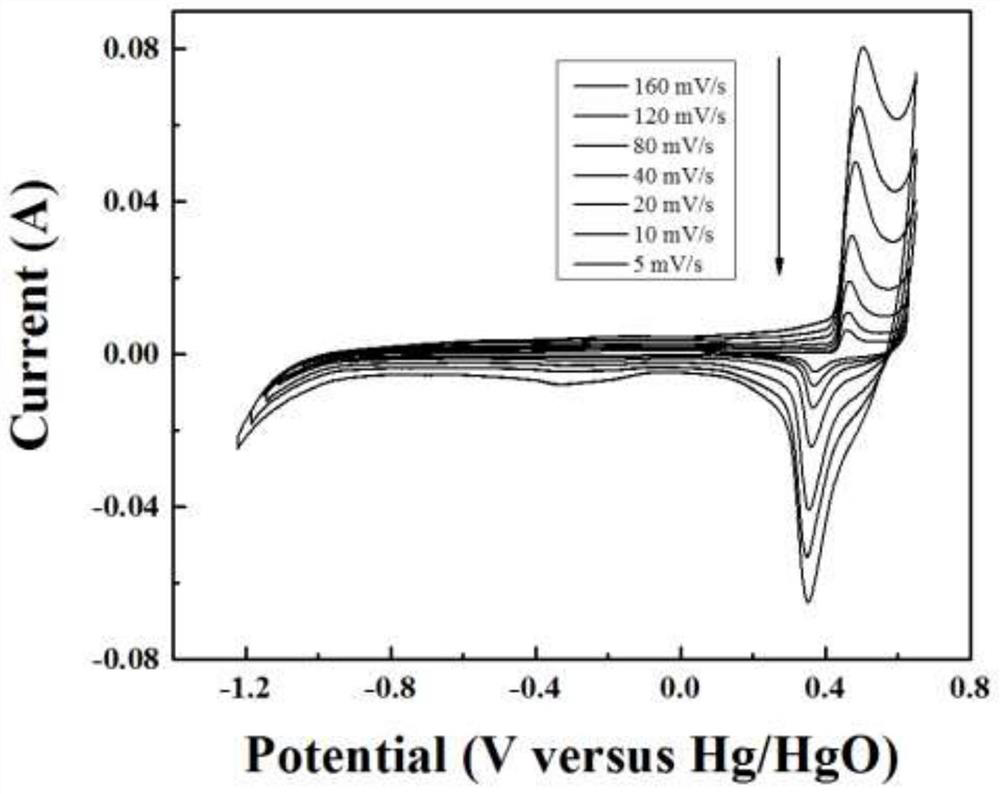

[0031] Embodiment 2 (La 1.67 Sr 0.33 )NiO 4 supercapacitor material

[0032] Prepared by sol-gel method (La 1.67 Sr 0.33 )NiO 4 . The process steps are as follows: use nitrates of various metal ions as raw materials to prepare La(NO 3 ) 3 , Sr(NO 3 ) 2 and Ni(NO 3 ) 2 aqueous solution, first pipette the La(NO 3 ) 3 Solution 33.4mL, Sr(NO 3 ) 2 Solution 6.6mL, Ni(NO 3 ) 2Put 20mL of the solution into a 250mL beaker, and add 0.12mol of citric acid to the beaker. Then add methanol to the beaker to dilute the solution by 100mL, stir until completely dissolved and then add 6mL of ethylene glycol. Then, the solution was moved into a water bath at 88°C, heated with stirring, and a uniform and transparent sol was formed for 55 minutes, and the sol was transferred into an oven at 180°C for heat treatment for 20 hours to form a xerogel precursor. Grind the dry gel precursor and transfer it to a tube furnace. In an oxygen atmosphere, first keep it at 200°C for 30 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com