Variable constant-current constant-voltage charging method

A technology of constant voltage charging and constant current charging, which is applied in the direction of secondary battery charging/discharging, charging/discharging current/voltage regulation, collectors, etc., and can solve problems such as prolonging charging time, battery scrapping, and adverse effects on battery life. achieve the effect of making up for the deficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

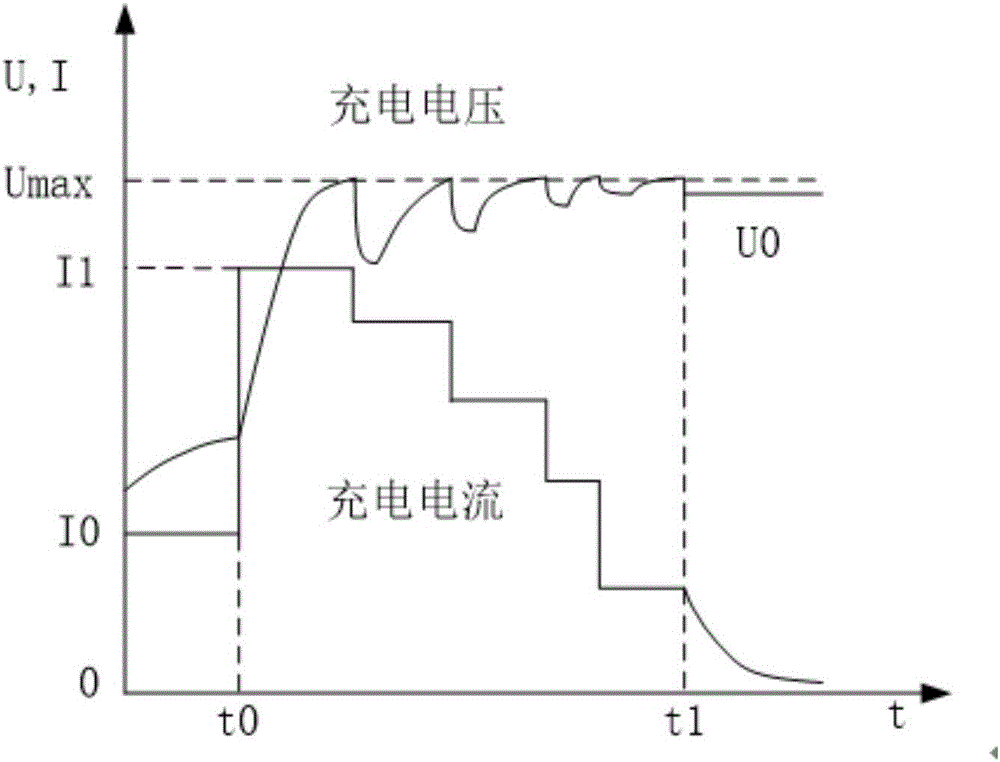

[0035] A variable constant current-constant voltage charging method includes: when the battery voltage is low, trickle charging is performed according to the sampled feedback information; when the battery voltage rises to the high current charging threshold, high current constant current charging is performed Mode, the charging current can only be gradually reduced during this process, and cannot reversely change; when the variable constant current charging phase is over, it enters the constant voltage charging phase, when the variable constant current charging current value decreases to 0.6 times the minimum constant current charging current , The program defaults to the end of variable constant current charging.

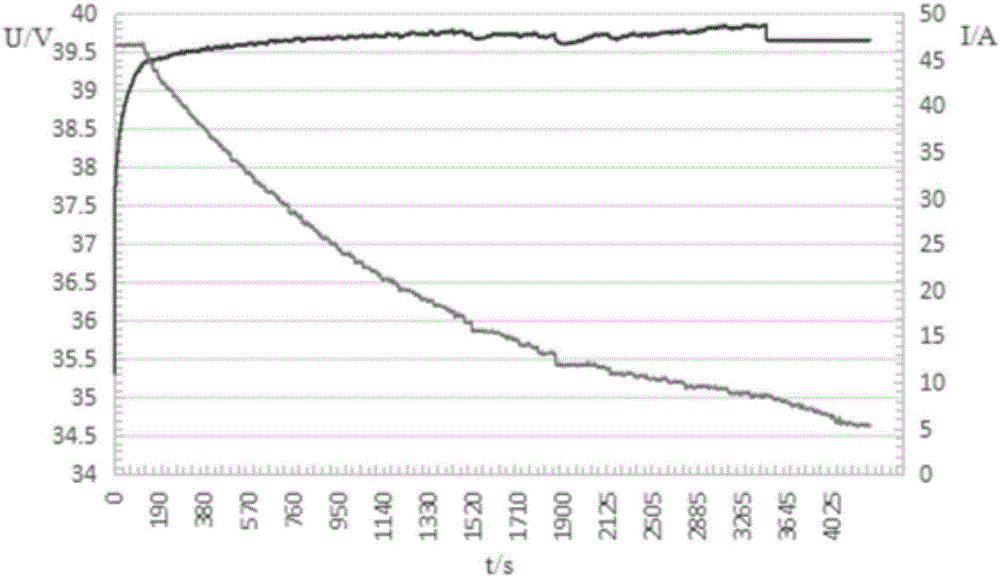

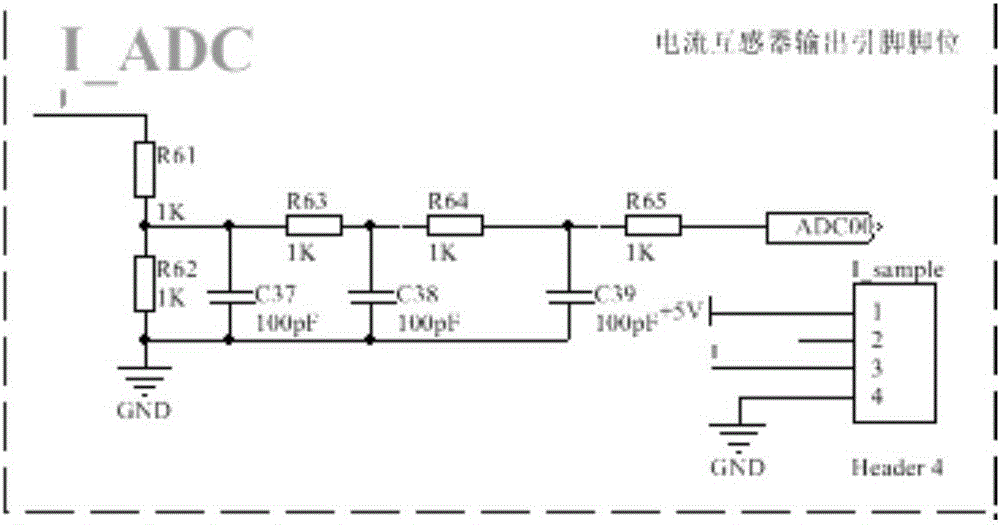

[0036] The control chip obtains the voltage, cell voltage, charging current and battery temperature information of the power battery through AD sampling.

[0037] When the battery voltage is higher than the upper limit voltage set by constant current charging, the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com