Outer sheath shielding layer stripping knife of high-voltage cable

A high-voltage cable and outer sheath technology, which is applied in the field of cable outer sheath test operation tools, can solve the problems of reduced efficiency, semi-conductive material residue, fragile glass, etc., and achieve safe and fast operation, improved efficiency, and easy portability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

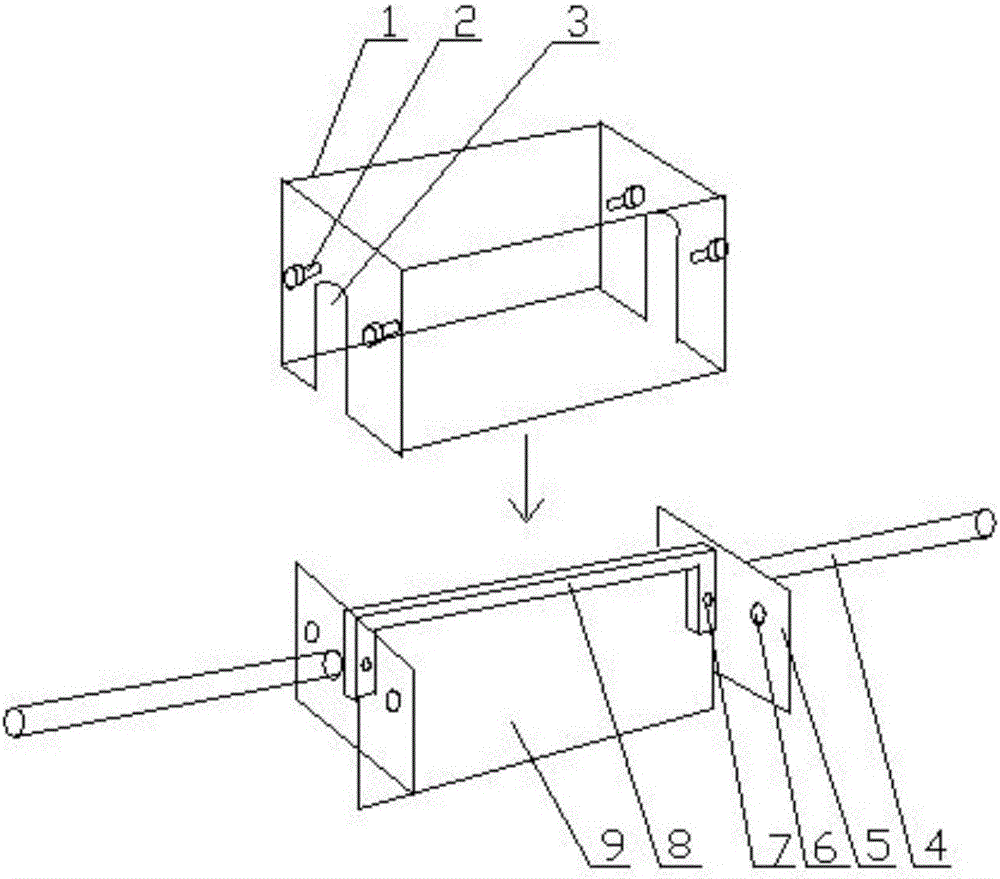

[0013] A high-voltage cable outer sheath shielding layer stripping knife, such as figure 1 As shown, it consists of two parts, the shell 1 and the knife rest group. The said knife rest group includes cylindrical handles 4 placed coaxially on both sides, and a knife rest plate 5 perpendicular to the handle is fixed at the opposite ends of the two handles. An I-shaped knife rest 8 with a groove inside is fixed between the knife rest plates parallel to each other. The rectangular sheet blade 9 is installed in the groove of the I-shaped knife rest, and passes The blade fixing bolt 7 fixes the blade, and a fixed shell bolt hole 6 is formed on both sides of the handle of the knife rest plate. Handle hole groove 3, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com