Packaging process for motor stator

A technology of motor stator and packaging technology, which is applied in electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve problems such as uneven end faces, motor jamming, and affecting normal operation of the motor, so as to ensure normal operation, The effect of smooth glue filling surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

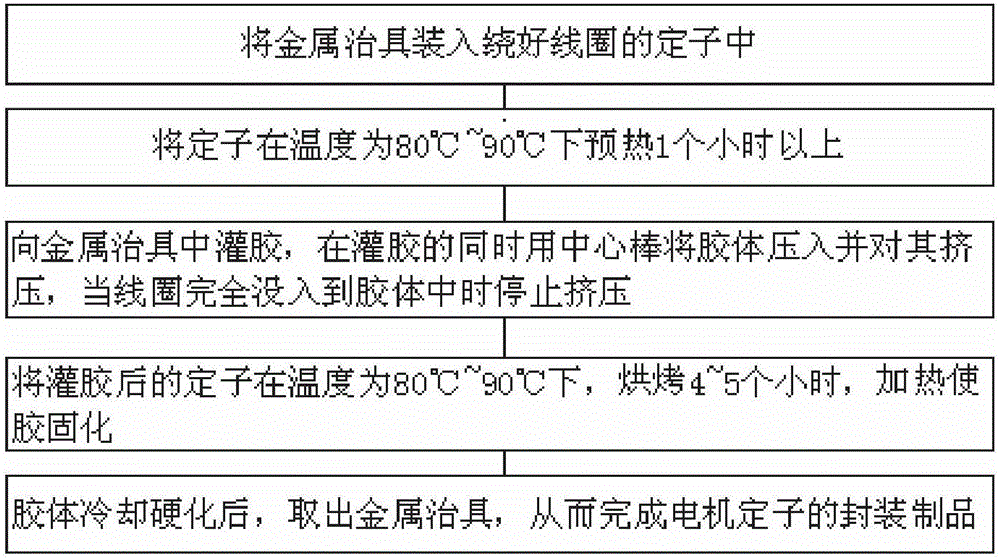

[0030] First, put the metal fixture into the stator with the copper wire coil; then preheat the stator at 80°C for 1 hour; pour liquid epoxy resin colloid into the metal fixture, and pour the glue at the same time Use the center rod to press the colloid in and squeeze it; stop the extrusion when the coil is completely submerged in the colloid; then bake the stator after filling the glue at a temperature of 80°C for 4 hours, and heat to cure the glue; After the colloid is cooled and hardened, use a hydraulic press to take out the metal jig to complete the packaged product of the motor stator.

[0031] In the present invention, liquid epoxy resin is poured into the stator of the motor, and a central rod is used to squeeze the glue while pouring the glue, and finally it is baked and solidified, cooled and molded to form a sealing layer in the stator of the motor. This glue filling process fully ensures that the inside of the stator can be completely filled with glue. It has the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com