Modular special-shaped inserting machine and its inserting head using rod-shaped linear motor

A technology of linear motors and special-shaped parts, applied in the direction of electrical components, electrical components, etc., can solve the problems of low work efficiency and high labor costs, achieve high work efficiency, efficient plug-in operations, and broaden the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

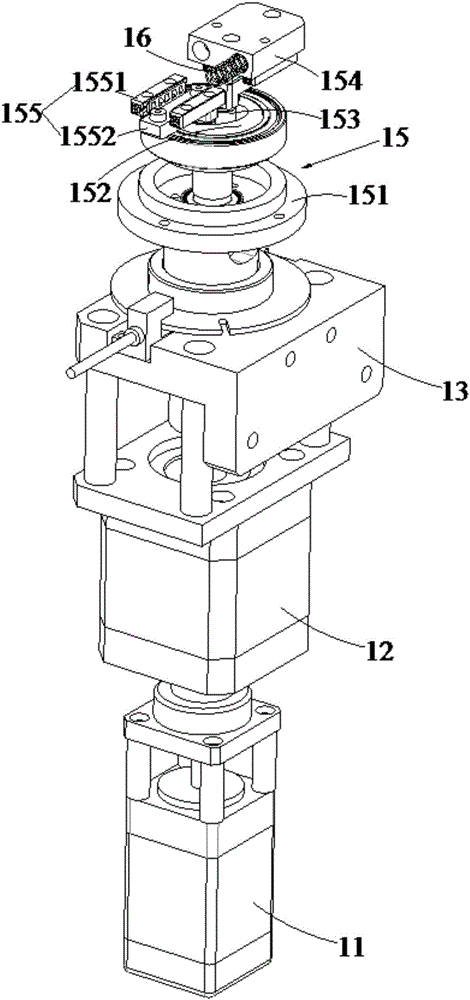

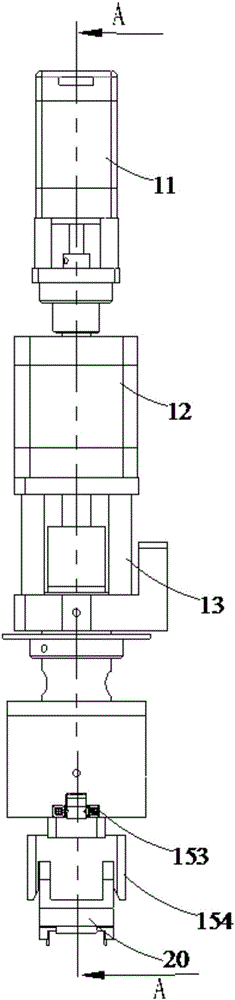

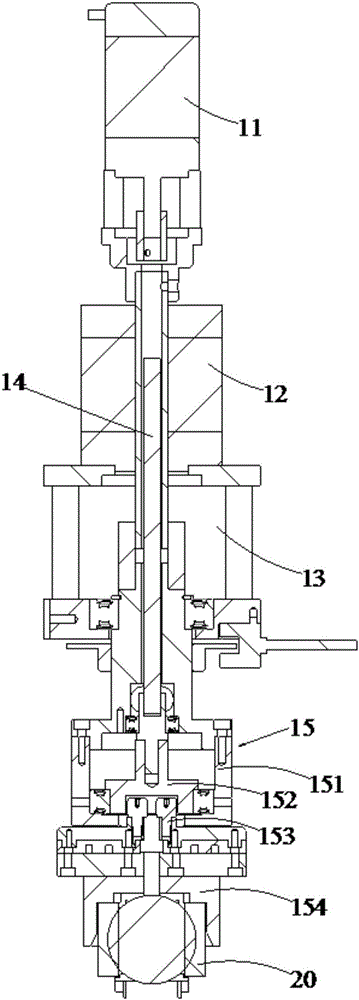

[0031] Such as Figure 1 to Figure 5 As shown, this embodiment 1 provides a plug-in head of a modular special-shaped plug-in machine, including a clamping motor 11, a rotating motor 12, an unpowered main shaft 13, a flexible steel wire shaft 14 and a clamping member 15, and the clamping member 15 Including connection seat 151, ellipse connector 152, precision roller bearing 153, mechanical finger 154 and cross roller guide rail 155, the output shaft of clamping motor 11 is connected with one end of flexible steel wire shaft 14, and the other end of flexible steel wire shaft 14 is connected with The connecting seat 151 is connected, the elliptical connecting piece 152 is connected with the connecting seat 151, one end of the precision roller bearing 153 is embedded in the elliptical connecting piece 152, the other end of the precision roller bearing 153 is connected with the cross roller guide rail 155, and the cross roller guide rail 155 Connected to the mechanical finger 154 ...

Embodiment 2

[0037] Such as Figure 6 to Figure 9 As shown, this embodiment provides a modular plug-in machine for special-shaped parts using a rod-shaped linear motor, including a frame 1, an X-axis rod-shaped linear motor 2, a Y-axis rod-shaped linear motor 3, a Z-axis rod-shaped linear motor 4, and a plug-in head 5. The assembly line 6 and the controller whose width can be adjusted automatically. The controller is set in the frame 1 for automatic operation. X-axis rod-shaped linear motor 2, Y-axis rod-shaped linear motor 3, Z-axis rod-shaped linear motor 4, plug-in Both the head 5 and the assembly line 6 are connected to the controller, the assembly line 6, the X-axis rod-shaped linear motor 2 and the Y-axis rod-shaped linear motor 3 are all arranged on the frame 1, and the X-axis rod-shaped linear motor 2 is arranged on the Y-axis rod-shaped linear motor 3 Above, the X-axis rod-shaped linear motor 2 can move on the Y-axis rod-shaped linear motor 3, the Y-axis rod-shaped linear motor 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com