Sterilization unit for packaging material

A technology for sterilization devices and packaging materials, which is applied in the directions of packaging sterilization, electrical equipment construction parts, disinfection, etc., can solve the problems of inapplicable insulation technology and unsuitable insulation technology, and achieve improved electrical insulation performance and low weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

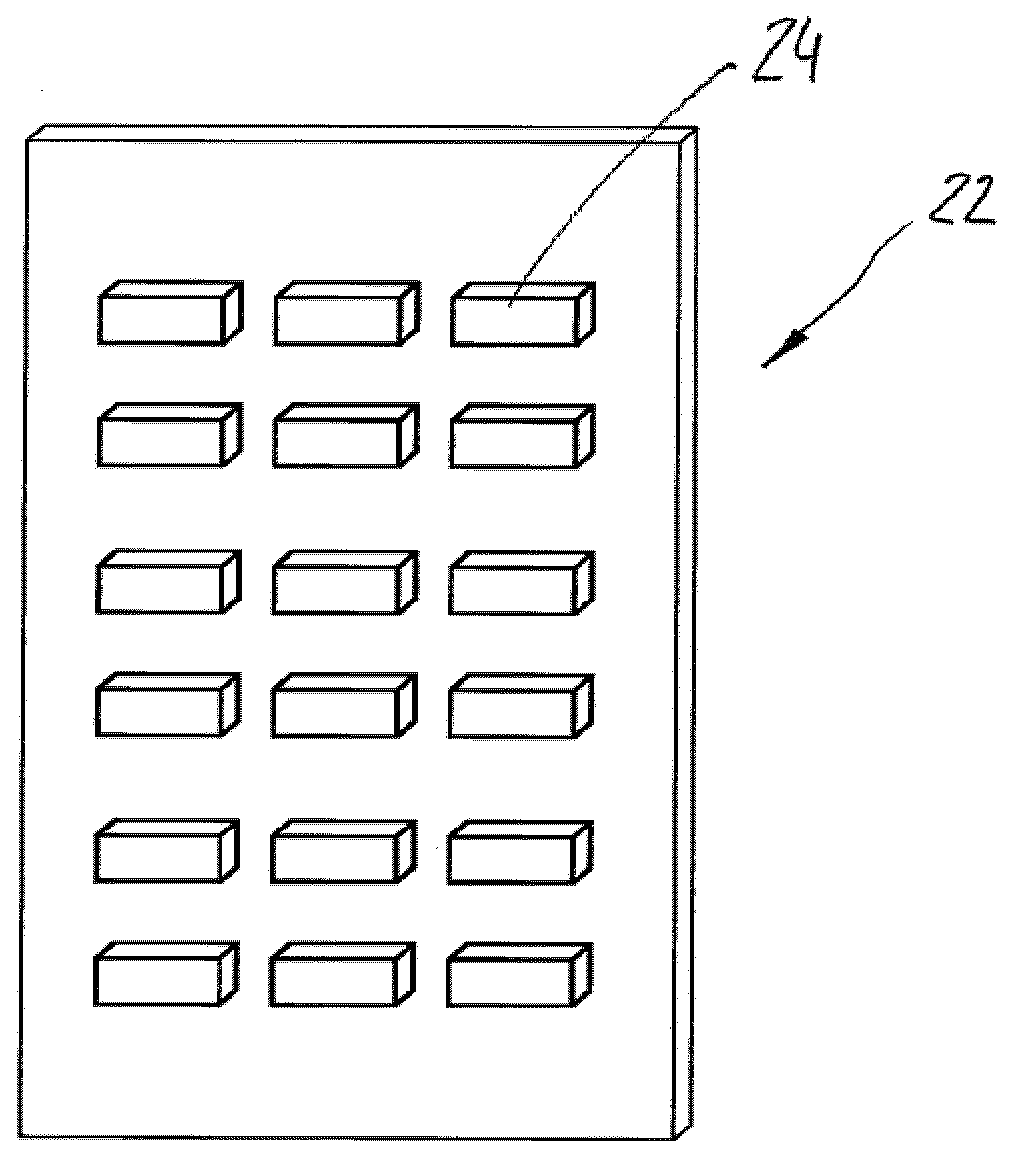

[0049] now refer to Figure 1a , showing the electronic assembly 22 . Electronic assembly 22 includes a plurality of electronic components 24 .

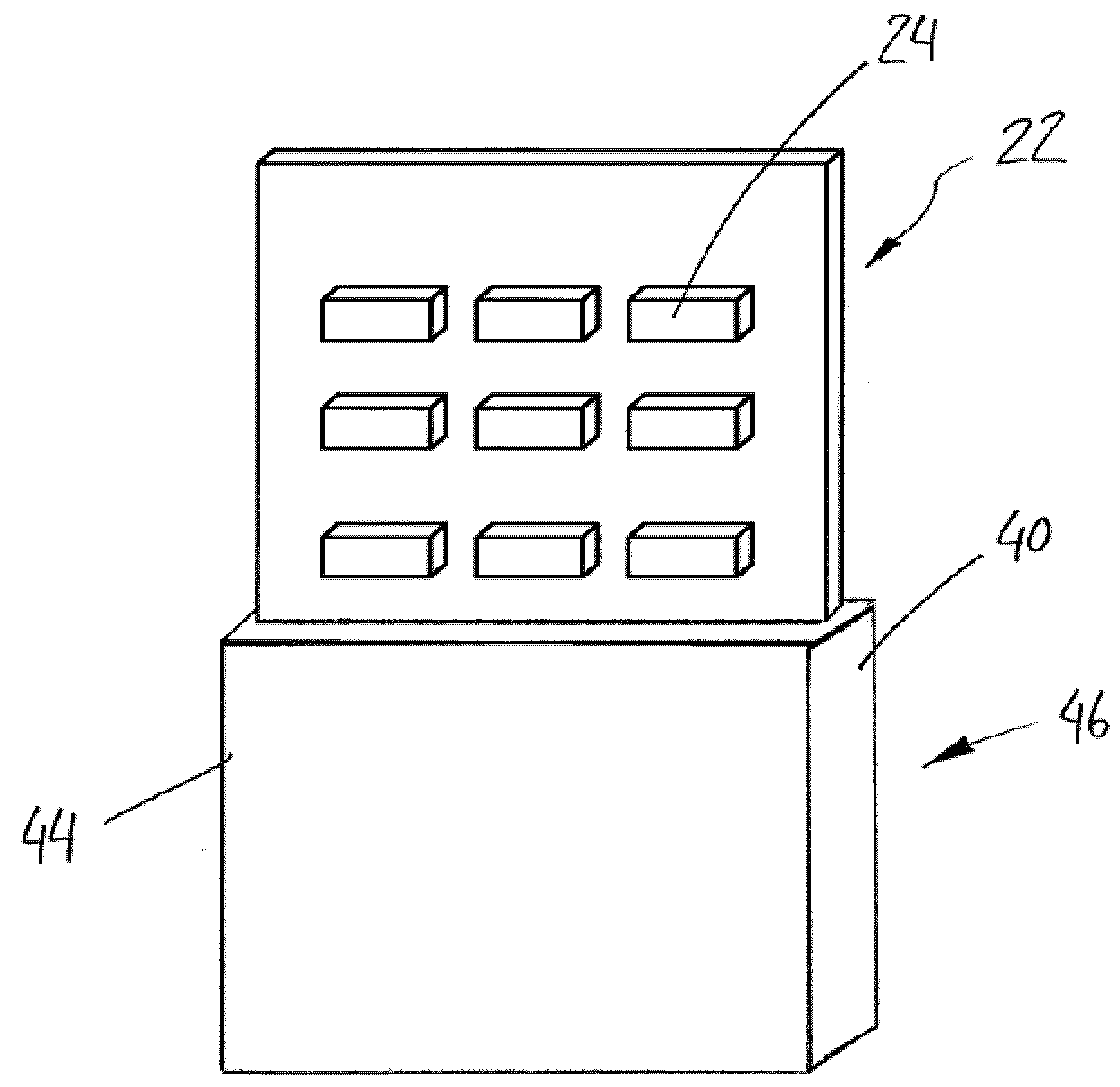

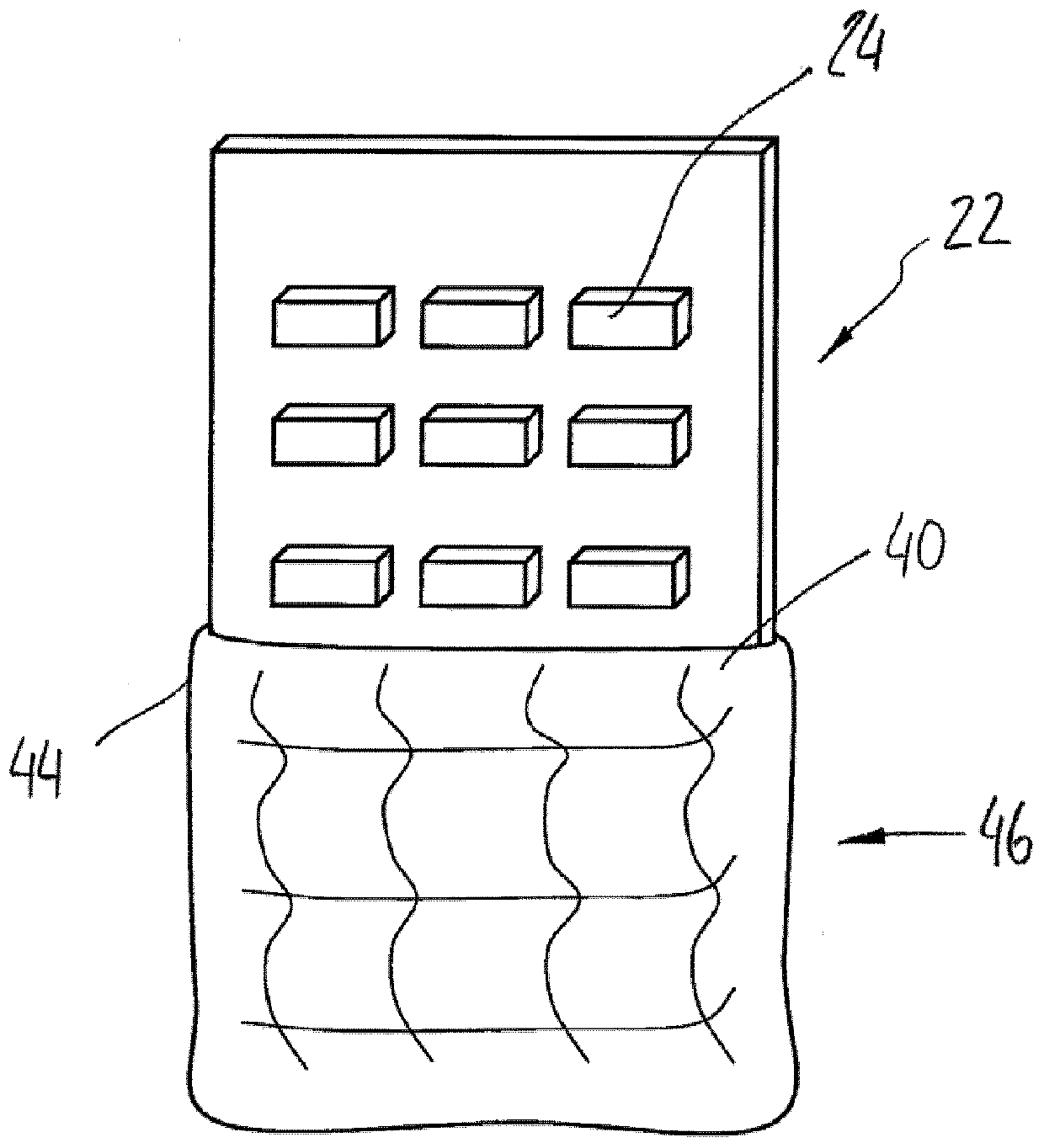

[0050] Figure 1b An insulating layer 46 is shown disposed partially over the electronic component 22 . Electronic components 24 that operate, create or process potentials or voltages exceeding at least a first voltage threshold are covered by a solid insulating layer 40. The solid insulating layer 40 is provided by potting. The solid insulating layer 40 includes a substantially planar outer surface 44 and an inner surface. An inner surface of the solid insulating layer 40 is at least partially in contact with the electronic component 22 . The upper region of the electronic components 22 is not covered by the insulating layer 46 because the components disposed in this region do not operate, create, use or process voltages that exceed the first voltage threshold. In this case, an additional solid insulating layer is unnecessary. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com