Manufacturing process for aluminum alloy bus wheel hub by gravity compression casting

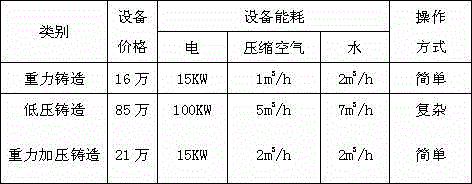

A pressurized casting and manufacturing process technology, applied in the field of gravity pressurized casting aluminum alloy bus hub manufacturing process, can solve the problems of complex production process, high cost, high melting cost, etc., to achieve compact internal structure and low production cost , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

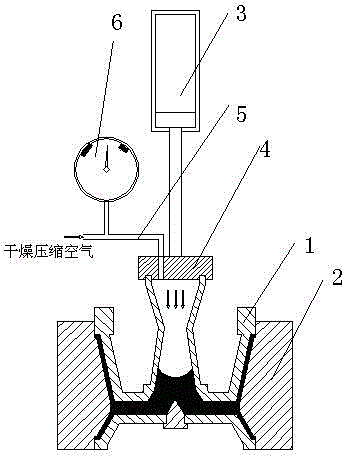

[0020] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

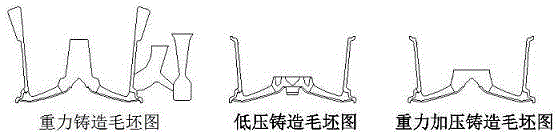

[0021] Such as figure 1 Shown in -2, the present invention is a kind of manufacturing process of gravity pressure casting aluminum alloy bus hub, and described manufacturing process comprises the following steps:

[0022] (1) Mold closing: combine the upper mold and the lower mold of the hub to form the mold cavity;

[0023] (2) Casting: Pour molten aluminum at a temperature of 720°C±5°C into the mold cavity for casting;

[0024] (3) Blocking and sealing: quickly seal the mold cavity after casting, and the time interval from the completion of casting to sealing the mold cavity is less than 10 seconds;

[0025] (4) Pressurization and filling stage 1: add dry compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com