Washing machine damping device

A shock absorption device and a washing machine technology, applied in the field of washing machines, can solve the problems of large damping force, small damping force, supply, etc., and achieve the effects of avoiding up and down movement, improving vibration and noise level, and improving shock absorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

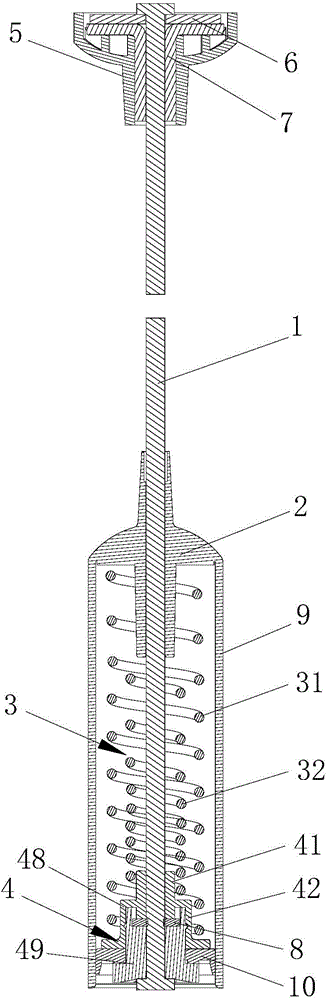

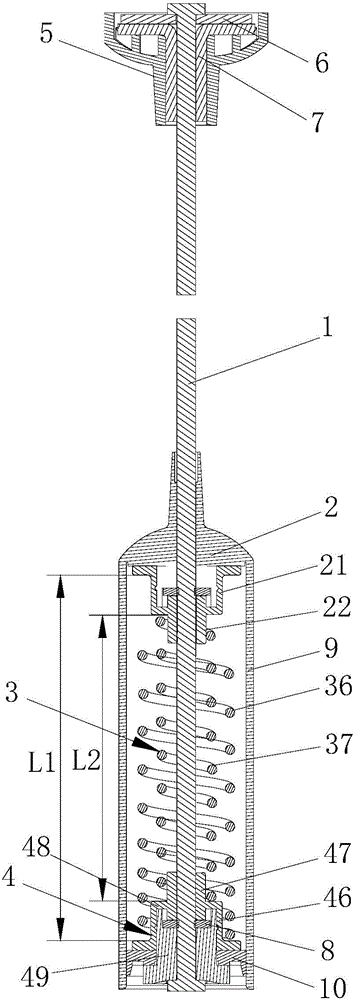

[0042] Such as figure 1As shown, two springs 31, 32 are arranged between the bracket 2 and the spring seat 4 described in this embodiment. The lengths of the two springs 31, 32 are different, and the lower ends are fixed with the spring seat 4. When the amplitude is small, the spring The distance between the seat 4 and the bracket 2 changes little, and only the longer spring 31 acts to produce less damping; when the amplitude is large, the distance between the spring seat 4 and the bracket 2 changes greatly , the shorter spring 32 is also compressed, and at this time, the two springs 31 and 32 both work to produce greater damping and suppress vibration.

Embodiment 2

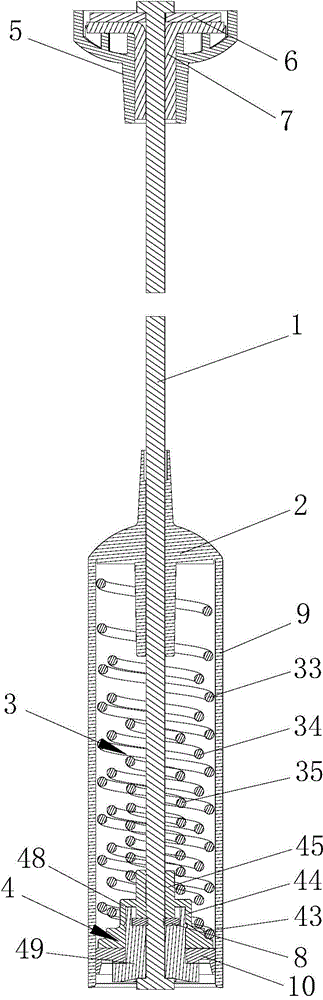

[0044] This embodiment makes a further improvement on the basis of Embodiment 1. The spring 32 with short length in the spring group 3 gradually increases in stiffness coefficient from top to bottom, and / or, the pitch of the spring 32 gradually decreases from top to bottom ( refer to figure 1 ), from top to bottom is the extending direction from one end of the bracket 2 to one end of the spring seat 4.

[0045] The change characteristic of the stiffness coefficient / pitch of the spring can slow down the change of the damping force, especially prevent the sudden increase of the damping force when the spring works.

Embodiment 3

[0047] In this embodiment, a further improvement is made on the basis of the above-mentioned embodiments. There are two springs 31 and 32 with different lengths, and the longer spring 31 is arranged on the outer ring of the shorter spring 32 .

[0048] The upper end surface of the spring seat 4 connecting the springs 31, 32 gradually lowers from the center to the outer periphery to form a stepped boss structure. Such as figure 1 As shown, the lower end of the shorter spring 32 is sleeved on the outer periphery of the centermost boss 41 of the spring seat 4 , and the longer spring 31 is sleeved on the outer periphery of the lower boss 42 of the outer ring. The fixing structure can prevent the two springs from shaking and being entangled when the suspender is working, which affects the damping performance.

[0049] Alternatively, for two springs with different lengths, the shorter spring is arranged on the outer ring of the longer spring. The upper end surface of the spring se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com