Surface acoustic wave filter and manufacturing method thereof

A surface acoustic wave and manufacturing method technology, applied in the direction of impedance network, electrical components, etc., can solve the problems of increasing the manufacturing cost of surface acoustic wave devices, damaging metal electrodes or leads, and increasing wafer manufacturing costs, so as to weaken pyroelectric effect, lower temperature expansion coefficient, and improved power resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0047] Next, the structure of the surface acoustic wave filter according to Embodiment 1 of the present invention will be described in detail.

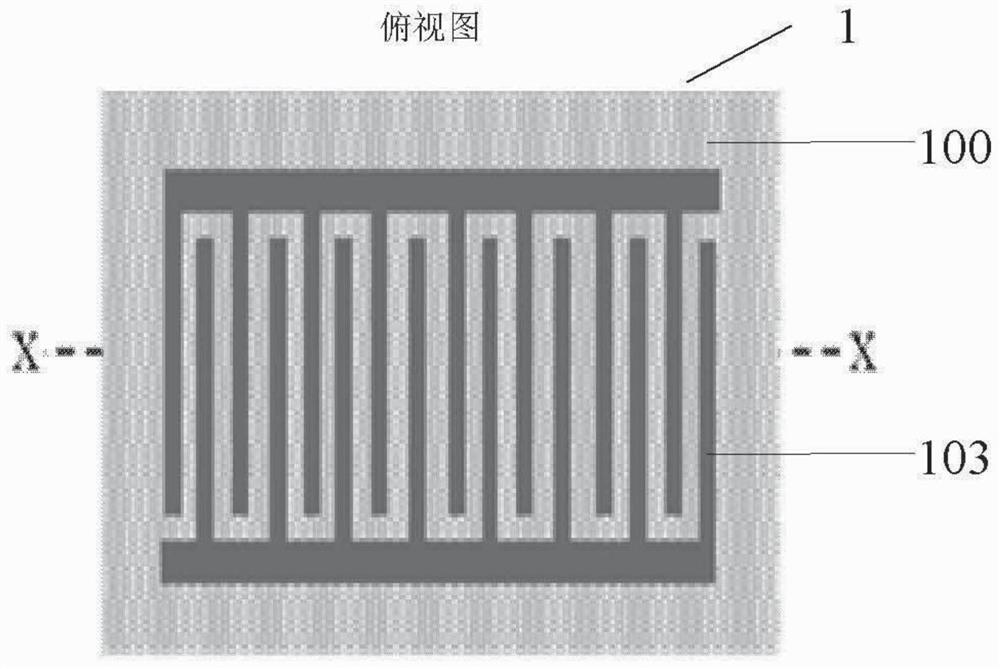

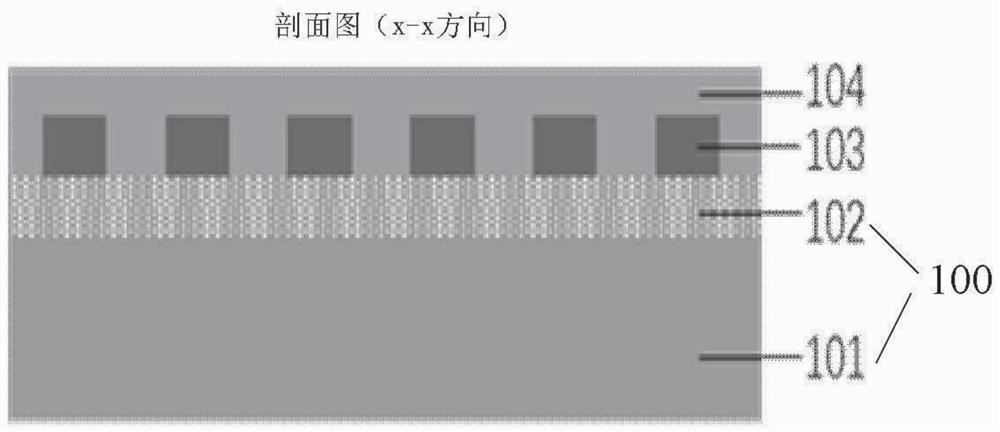

[0048] figure 1 is a plan view obtained when the surface acoustic wave filter according to Embodiment 1 of the present invention is observed from a plan perspective, wherein, figure 1 The top view in Schematic only schematically shows a part of the SAW filter and / or resonator structure, which can be other Normal-SAW, TC-SAW, IHP-SAW filter and / or resonator structures (Note: Resonance The resonator is part of the filter, and multiple resonators can be connected by circuit to form a filter). figure 2 This is a cross-sectional view showing the surface acoustic wave filter according to Embodiment 1 of the present invention when viewed from the X-X direction.

[0049] like figure 1 As shown, the surface acoustic wave filter 1 includes a piezoelectric layer 100 and interdigital electrodes 103 formed on the piezoelectric layer 100 .

[...

Embodiment approach 2

[0066] As described above, in Embodiment 1 of the present invention, as figure 2 As shown, the above-mentioned doping structure 102 is entirely formed in the surface direction of the above-mentioned piezoelectric layer 100 .

[0067] In contrast to this, in Embodiment 2 of the present invention, such as Figure 5 As shown, the above-mentioned doping structure 102 is locally formed in the surface direction of the above-mentioned piezoelectric layer 100 .

[0068] Similarly, the piezoelectric layer 100 is doped with lithium ions or lithium oxides by ion implantation, but from the viewpoint of doping effect, the same doping effect can be obtained regardless of whether lithium ions or lithium oxides are selected.

[0069] Also, similar to the first embodiment, according to the above-described configuration of the second embodiment, it is also possible to obtain the same Figure 8 Similar performance indicators of the SAW filter 1 in the middle and low frequency bands can also b...

Embodiment approach 3

[0074] Next, in Embodiment 3, the manufacturing method of the surface acoustic wave filter according to Embodiment 1 of the present invention will be described in detail.

[0075] Image 6 It is a process sequence diagram showing the process of forming the dopant structure 102 entirely in the surface direction of the surface acoustic wave filter 1 according to Embodiment 1 of the present invention.

[0076] First, as Image 6 As shown in (a), the piezoelectric layer 100 is formed using a piezoelectric crystal composed of lithium tantalate, and then the piezoelectric crystal is prepared to be doped with lithium ions or lithium oxide by using an ion implantation technique.

[0077] Second, if Image 6 As shown in (b), lithium ions or lithium oxide are implanted by doping in the depth direction of the piezoelectric layer 100, whereby the doping structure 102 is locally formed in the depth direction of the piezoelectric layer 100, and at the same time, the piezoelectric layer 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com