A fixing mechanism of a flocculant dispenser and a washing machine

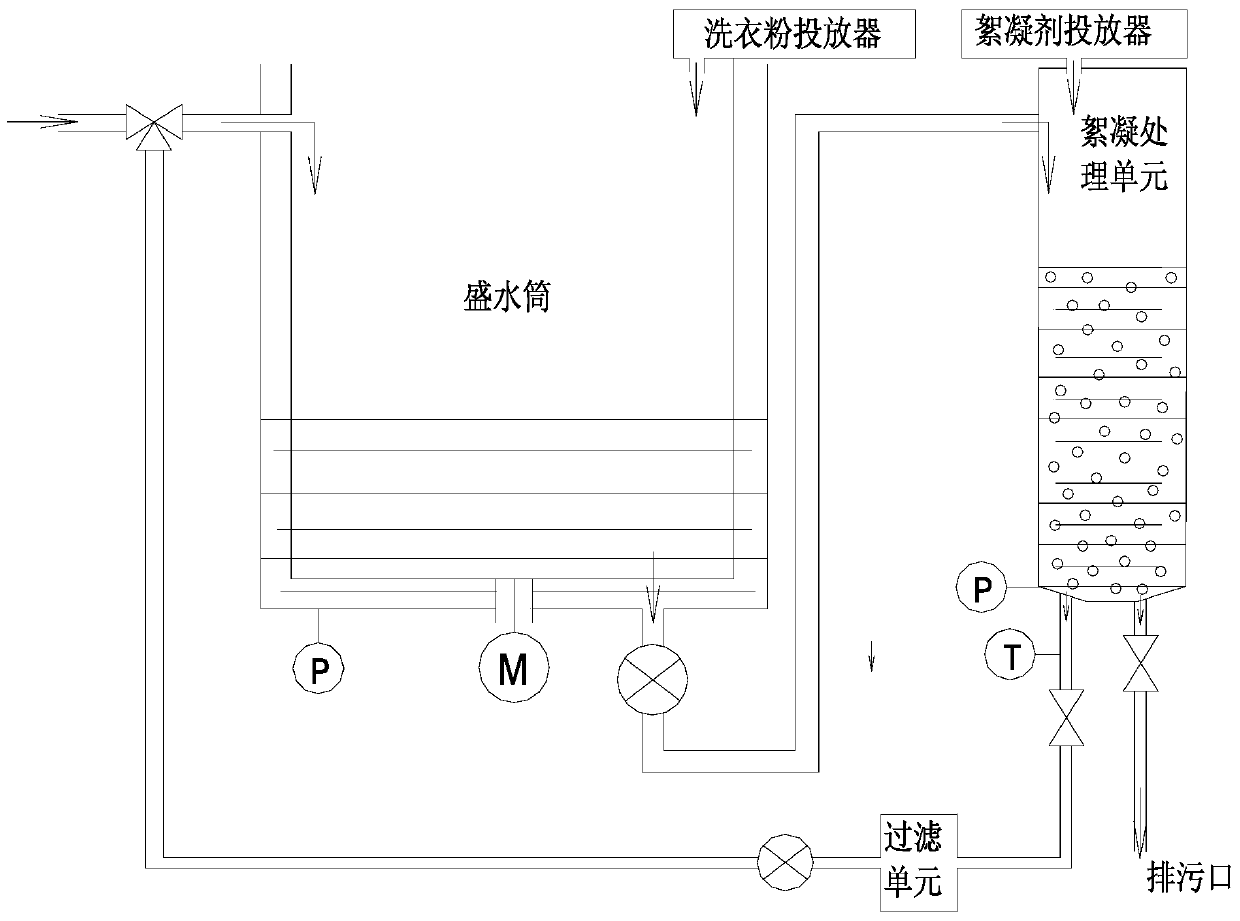

A technology of fixing mechanism and dispenser, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of inaccurate dosage of flocculant, reduce the accuracy of flocculant dispenser, etc. The effect of improving the degree of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

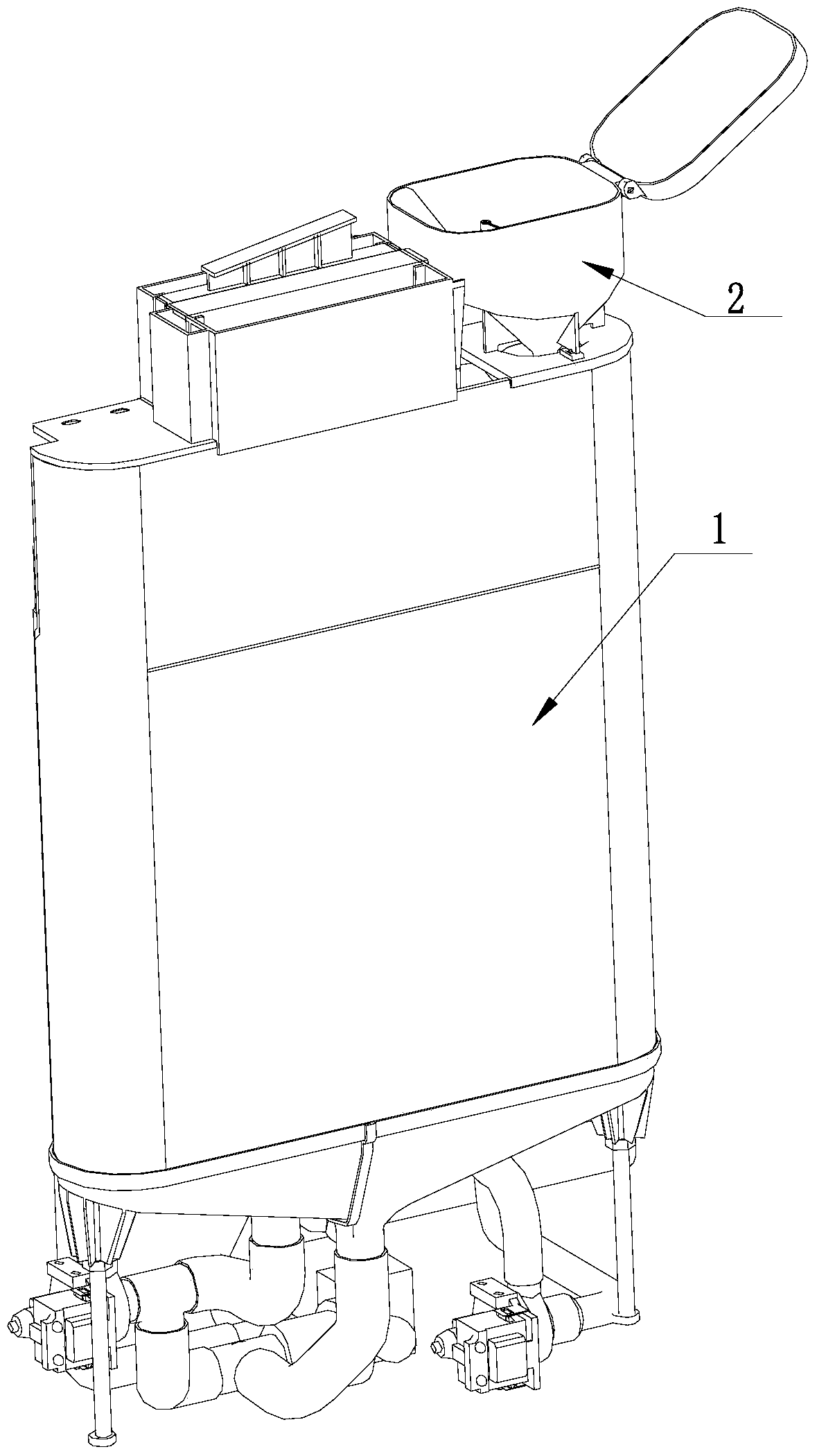

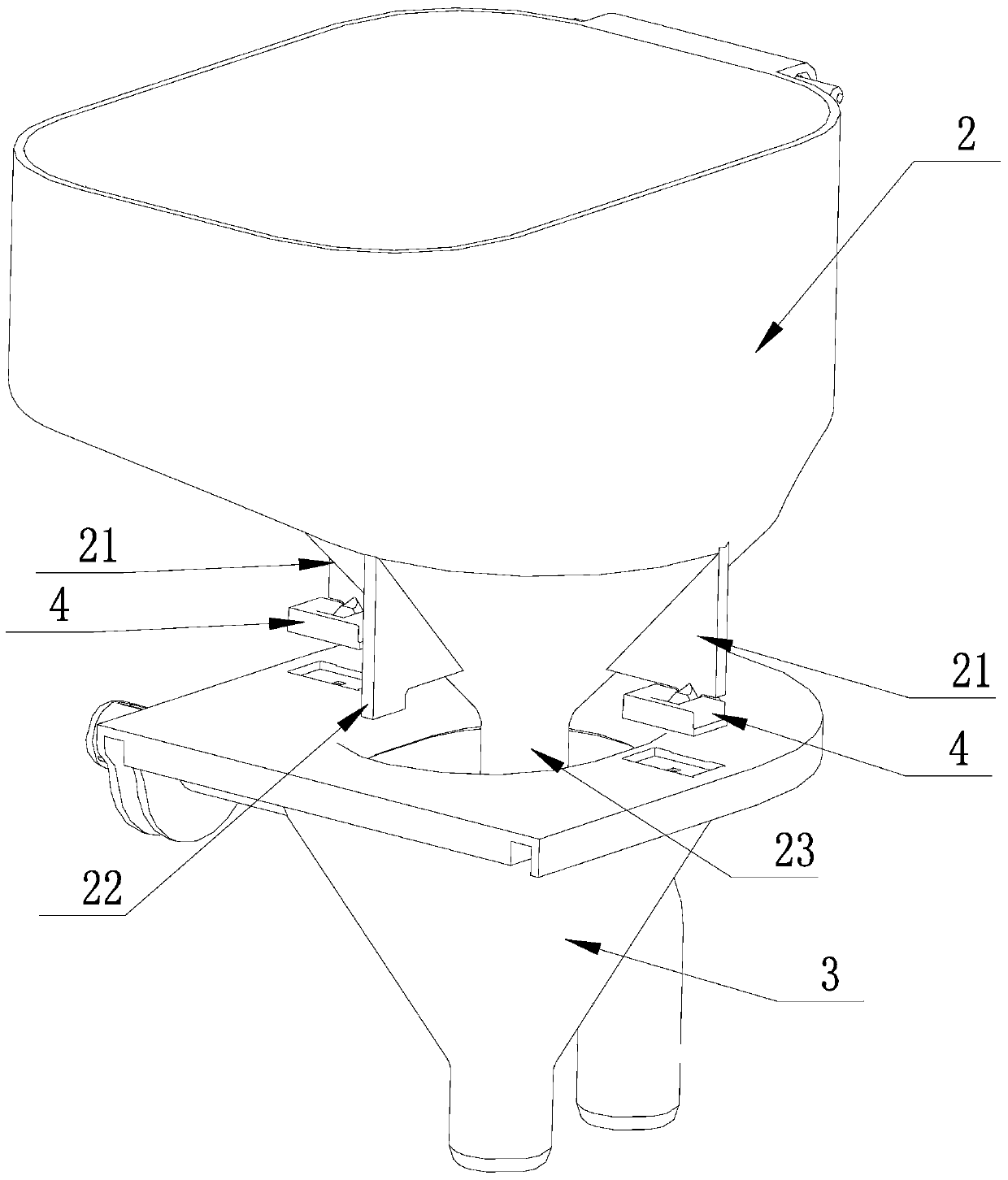

[0040] Such as Figure 1 to Figure 7 As shown, in this embodiment, the lower end of the installation rib 21 is provided with a horizontally extending and protruding insertion protrusion 24; 24 plug fixed slots 41. The flocculant dispenser and the shock absorber can be assembled and disassembled by fast insertion through the insertion cooperation between the insertion protrusion and the slot, so as to achieve the purpose of improving the convenience of assembly under the premise of simplifying the fixing mechanism as much as possible.

[0041] In this embodiment, the shock-absorbing pad 4 is made of rubber material that can provide high damping and buffering force, so as to improve the effect of shock-absorbing and buffering.

[0042] Such as Figure 5 to Figure 7As shown, in this embodiment, the shock absorbing pad 4 is provided with a slot 41 for inserting and fixing the mounting rib 21 . The cross-section of the slot 41 of the shock-absorbing pad 4 is a trapezoid that gra...

Embodiment 2

[0045] Such as Figure 4 As shown, in this embodiment, the water inlet structure of the flocculation bucket 1 includes a water inlet chamber 3, the water inlet chamber 3 is funnel-shaped, and the top plate 31 of the water inlet chamber 3 is provided with a flocculant dispenser 2. The mouth 2 extends into the interior of the chamber and is an opening 32 for feeding; the top plate 31 on the outer periphery of the opening 32 is provided with a mounting groove 33 for fixing the shock pad 4 . The outer peripheral shape of the shock-absorbing pad 4 is set in an interference fit with the positioning groove 34 . Therefore, the shock absorbing pad can be quickly and firmly installed in the installation groove, and the purpose of quick assembly of the shock absorbing pad and the flocculation bucket is achieved.

[0046] In this embodiment, the bottom of the mounting groove 33 is provided with a downwardly recessed positioning groove 34; 42. By setting the positioning groove and the m...

Embodiment 3

[0049] Such as Figure 2 to Figure 4 As shown, in this embodiment, each installation rib 21 is arranged axially symmetrically with respect to the delivery port 23 of the flocculant dispenser 2, and each installation rib 21 extends radially along the delivery port 23, and the insertion protrusion 21 is provided with The insertion protrusion 24 extends along the tangential direction of the insertion port 23 .

[0050] Therefore, by extending the installation rib along the radial direction of the delivery port, the connection between the flocculant dispenser and the flocculation barrel is located close to the outer periphery of the flocculant dispenser, so as to reduce the stress at the connection and improve the reliability of the connection ; At the same time, the insertion protrusion is extended along the radial direction of the insertion port, so that the coverage area of the insertion protrusion is larger, and the reliability of the connection is further improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com