A washing machine and a control method therefor

A control method and technology of a washing machine, applied to the control device of the washing machine, other washing machines, washing devices, etc., can solve the problems of inability to heat sterilization and disinfection, and the time required for heating and washing, etc., and achieve simple structure, high heating efficiency, and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

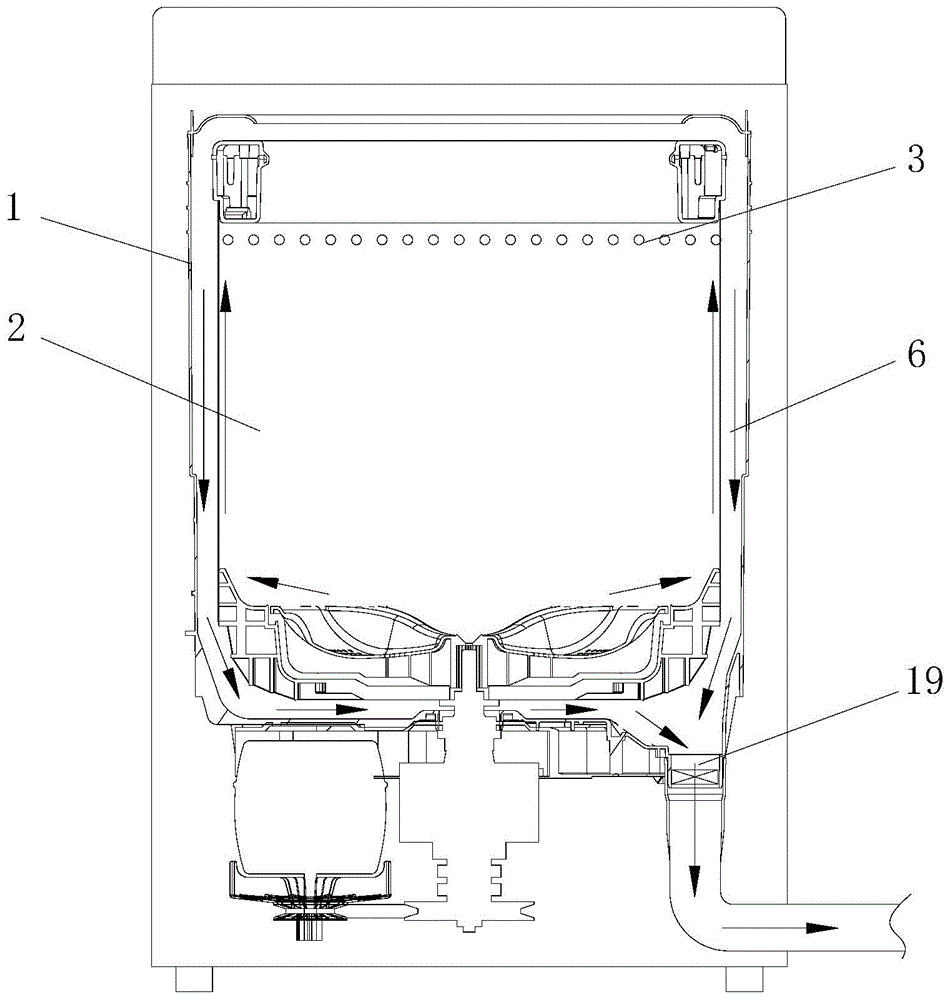

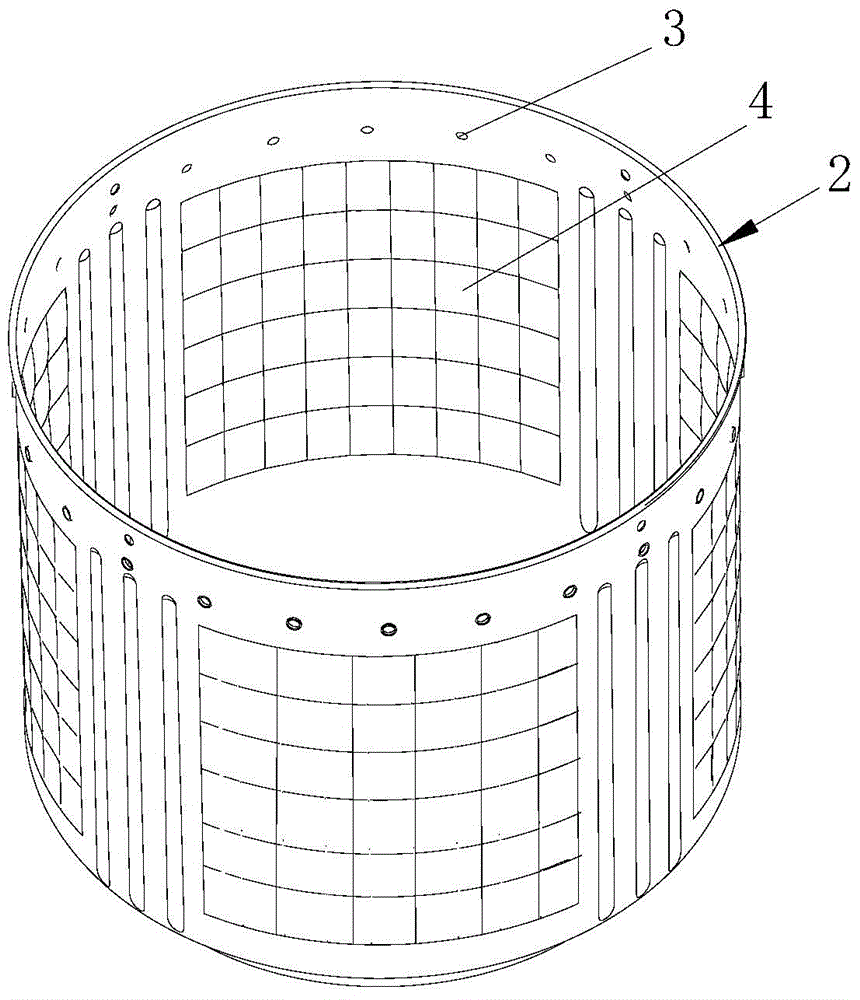

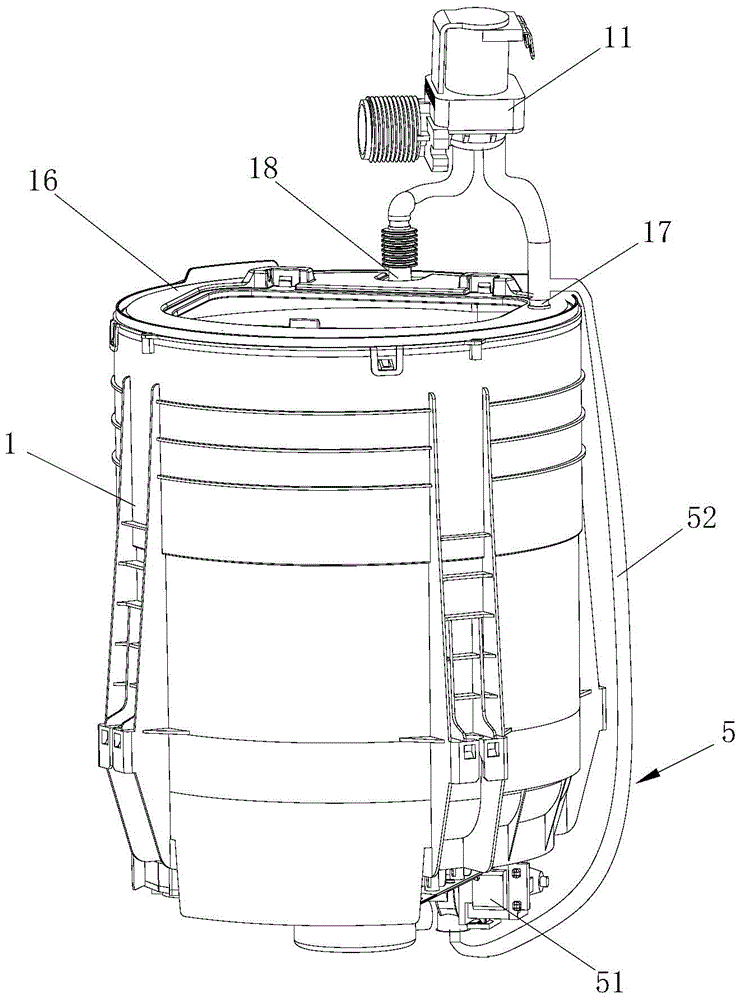

[0050] like image 3 As mentioned above, the top of the outer tub 1 of the washing machine in this embodiment is provided with an outer tub cover 16, and the outer tub cover 16 is provided with a first water spout 17 for feeding water into the inner tub 2 and a second water inlet 17 for feeding water into the chamber 6 between the inner and outer tubs. The water spout 18 and the first water spout 17 are respectively communicated with the water conduit 52 of the circulating water system and the water inlet flow valve 11 of the washing machine, and the second water spout 18 is also communicated with the water inlet flow valve 11. It is a reversing valve with one input and two outputs, which can detect the water intake in the inner tub 2 and the water intake in the chamber 6 between the inner and outer tubs (not shown in the figure).

Embodiment 2

[0052] like Figure 4 As mentioned above, the top of the outer tub 1 of the washing machine in this embodiment is provided with an outer tub cover 16, and the outer tub cover 16 is provided with a first water spout 17 for feeding water into the inner tub 2 and a second water inlet 17 for feeding water into the chamber 6 between the inner and outer tubs. The water spout 18 and the first water spout 17 are communicated with the water inlet flow valve 11 of the washing machine. The water inlet flow valve 11 detects the amount of water in the inner tub 2, and the water conduit 52 of the circulating water system feeds water to the inner tub through another circulating water inlet. 2; or the first water spray port 17 is connected with the water conduit 52 of the circulating water system and the washing machine water inlet flow valve 11 respectively, the second water spray port 18 is communicated with another washing machine water inlet valve, and the outer barrel is installed with a ...

Embodiment 3

[0054] The difference between this embodiment and the above-mentioned embodiment is that the outer tub cover 16 is further provided with another third water spray port for feeding water into the inner tub. The first water spray port is only connected with the water inlet flow valve of the washing machine, and the third water spray port is connected to The water conduit of the circulating water system is communicated (not shown in the figure).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com