Metal contamination immediate monitoring method of semiconductor wafer

A semiconductor and wafer technology, applied in the monitoring field of semiconductor manufacturing process, can solve problems such as measurement error, misjudgment, reduced lifespan or diffusion length measurement value, etc., to achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The method for real-time monitoring of metal contamination of semiconductor wafers of the present invention can be divided into low-temperature processing and high-temperature processing according to the processing temperature. Wherein, the metal pollution real-time monitoring method of the semiconductor wafer can be used to monitor the metal pollution of the following machines: 1. Low-temperature process machine: yellow light machine, etching machine, wet etching machine, ion implantation machine etc.; 2. High-temperature process machines: furnace tube machines, rapid annealing machines, physical vapor deposition machines, chemical vapor deposition machines, etc.

[0032] Hereinafter, a method for real-time monitoring of metal contamination of a semiconductor wafer according to an embodiment of the present invention is described, which is used in a low-temperature process.

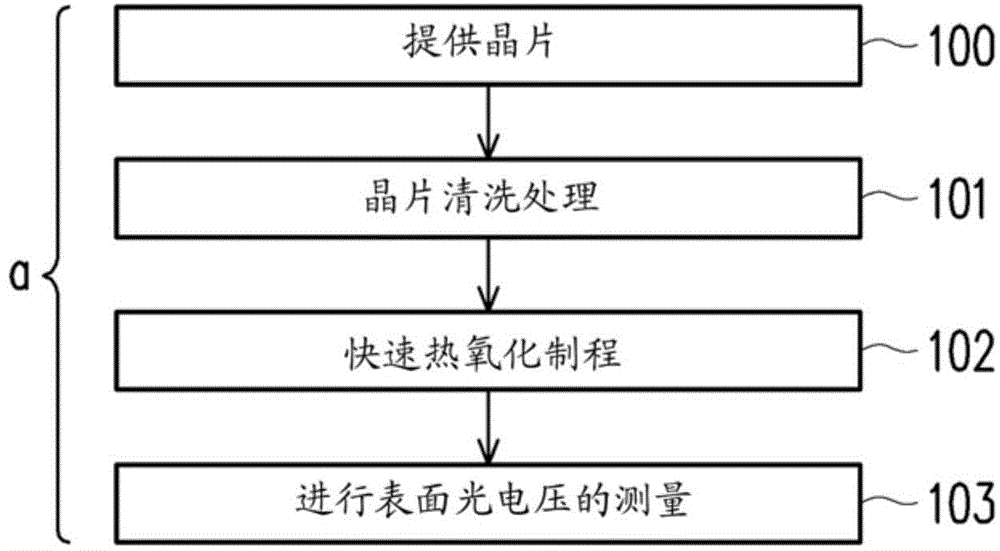

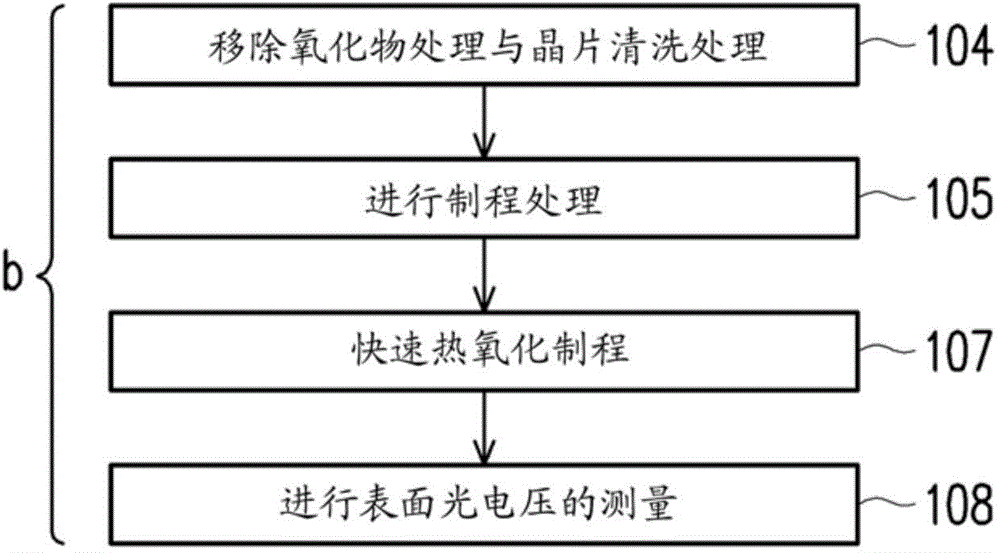

[0033] Figure 1A and Figure 1B It is a flow chart of a method for real-time monitoring of me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com