Multifunctional engineering vehicle

A kind of engineering vehicle and multi-functional technology, applied in the direction of cutting tools, manufacturing tools, program-controlled manipulators, etc., can solve problems such as danger, affecting construction efficiency, inconvenience, etc., and achieve the effect of large working range, simple structure and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

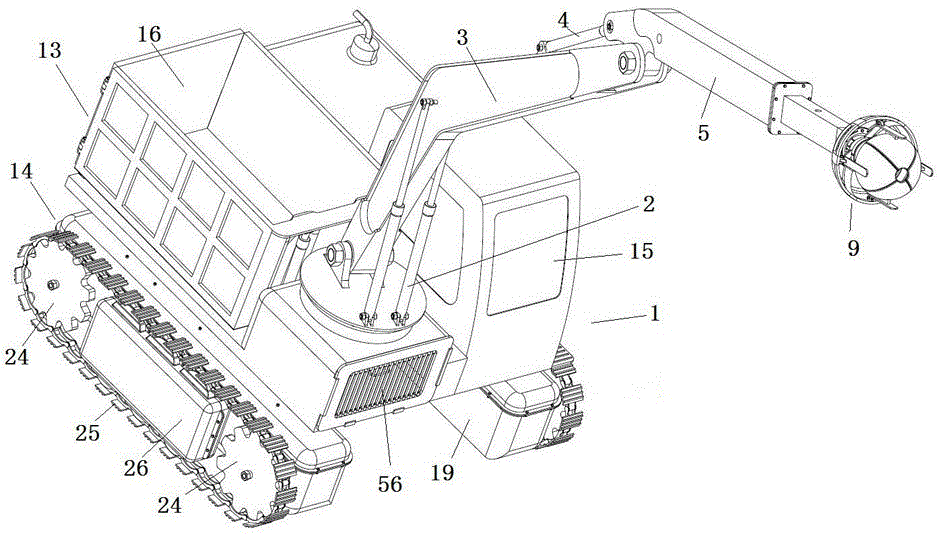

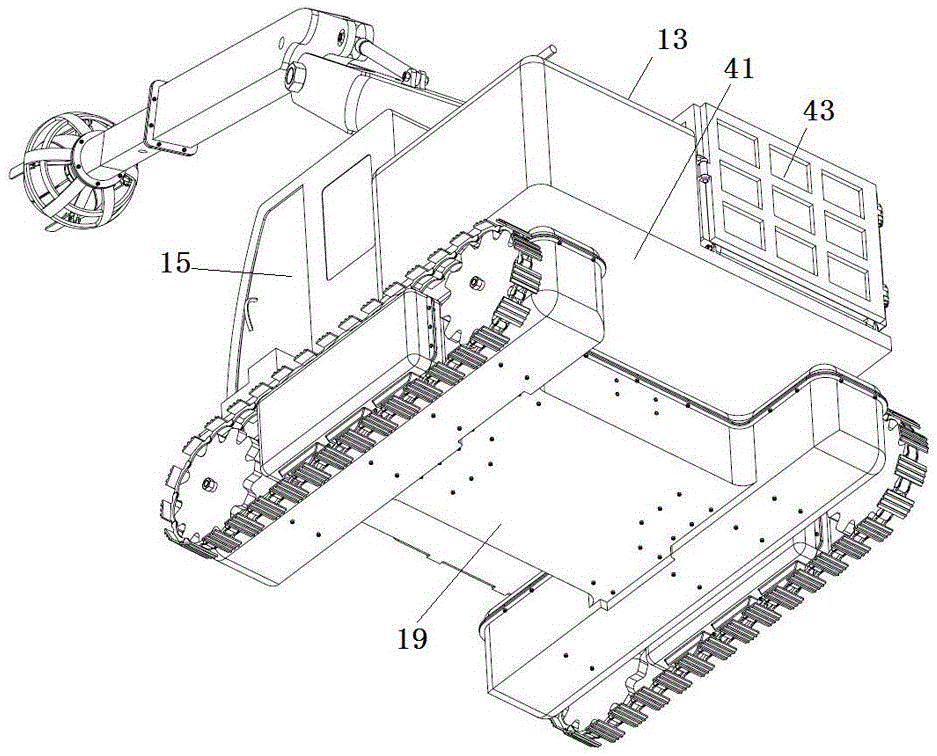

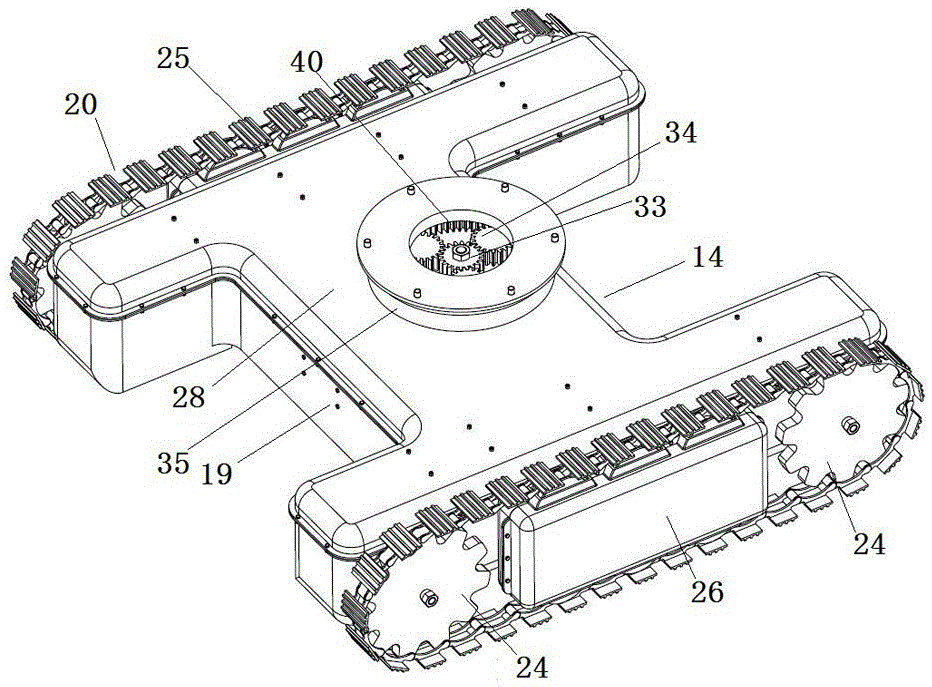

[0047] Such as Figure 1~29 As shown, a multifunctional engineering vehicle includes a car body 1, on which a boom 3 driven by a first cylinder 2 is hinged to rotate, and the end of the boom is hinged with a boom driven by a second cylinder 4. Rotating arm 5, the interior of the arm is provided with a sliding channel 6 extending along the length direction of the arm, and the end of the arm is provided with a telescopic rod 7, and one end of the telescopic rod is inserted into In the sliding channel and driven by the third cylinder 8 to slide, the end of the telescopic rod is screwed with a detachable actuator, and the actuator includes a pick-up mechanism 9, a scissors mechanism 10, a bucket mechanism 11, Breaking hammer mechanism 12.

[0048] In the embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com