Food grain drying equipment capable of preventing cereals from being charred

A technology for drying equipment and grains, applied in the direction of storing seeds by drying, etc., can solve the problems of broken grains, not paying attention to grain quality, etc., and achieve the effects of improving quality, improving drying effect, and slowing down the falling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, the technical solution of the present invention will be described in detail through specific examples.

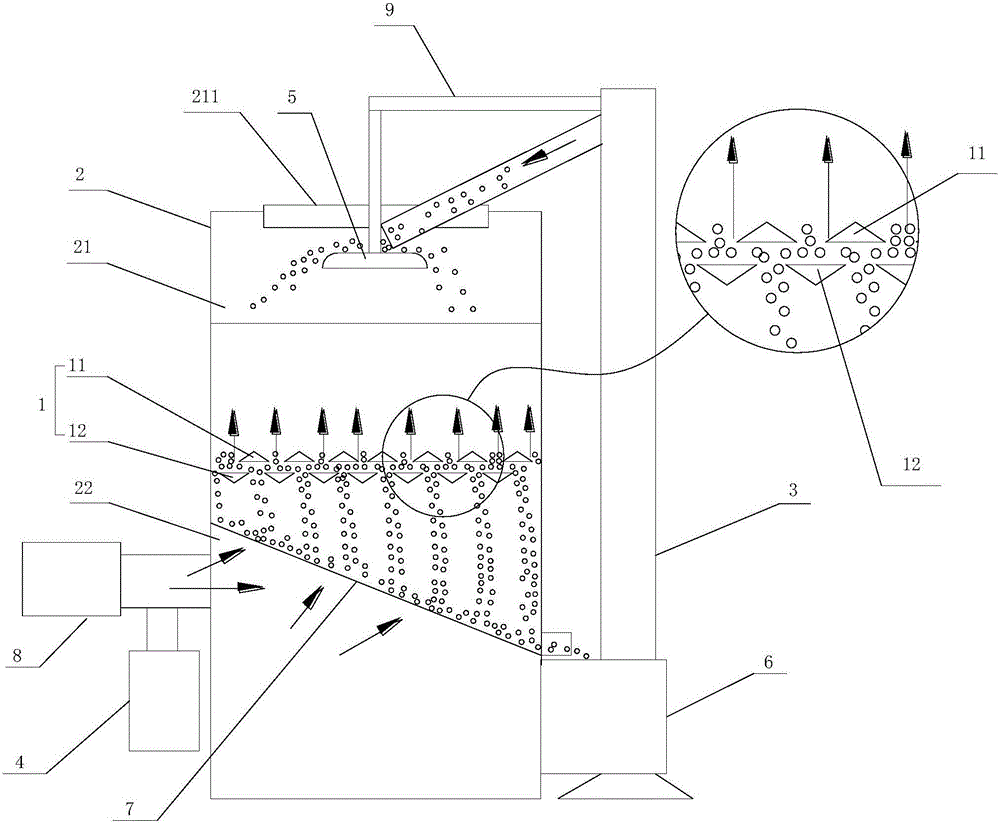

[0027] Such as figure 1 as shown, figure 1 It is a schematic structural diagram of a grain drying equipment for preventing grain scorching proposed by the present invention.

[0028] refer to figure 1 , a kind of anti-grain scorched grain drying equipment proposed in the embodiment of the present invention, comprising: a flow diversion assembly 1, a drying box 2, a lifting device 3 and a heating device 4, wherein:

[0029] The flow distribution assembly 1 is arranged in the drying box 2, and the flow distribution assembly 1 divides the inner cavity of the drying box 2 into a preheating chamber 21 and a drying chamber 22 arranged up and down. The flow distribution assembly 1 includes an upper distribution layer 11 and a Lower split layer 12;

[0030] The upper distribution layer 11 includes a plurality of upper distributing rollers arranged side by side in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com