Cold aggregate feeding and storing device of asphalt stirring station and operation method of cold aggregate feeding and storing device

A technology of asphalt mixing plant and cold aggregate, which is applied in mixer accessories, chemical instruments and methods, transportation and packaging, etc. It can solve the problems of poor sealing performance of the shed, low land use efficiency, and environmental pollution caused by dust, and achieve improvement The construction environment, the effect of preventing dust from escaping, and a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

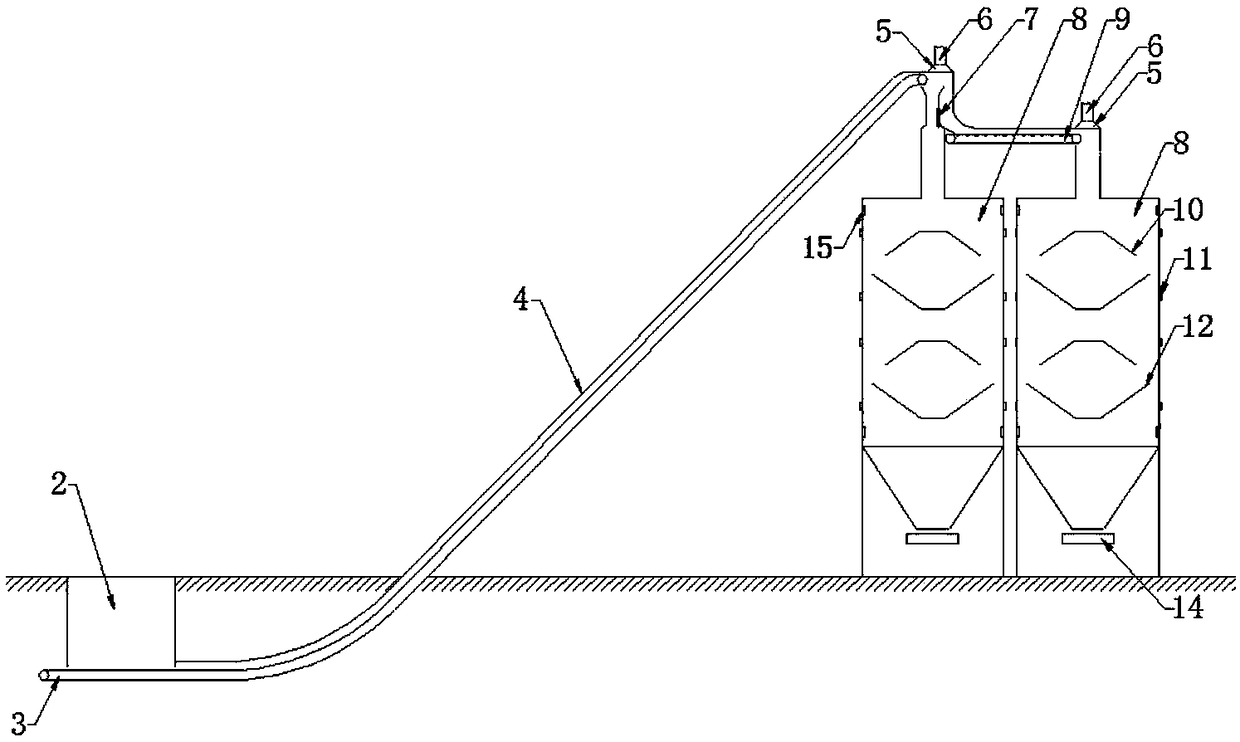

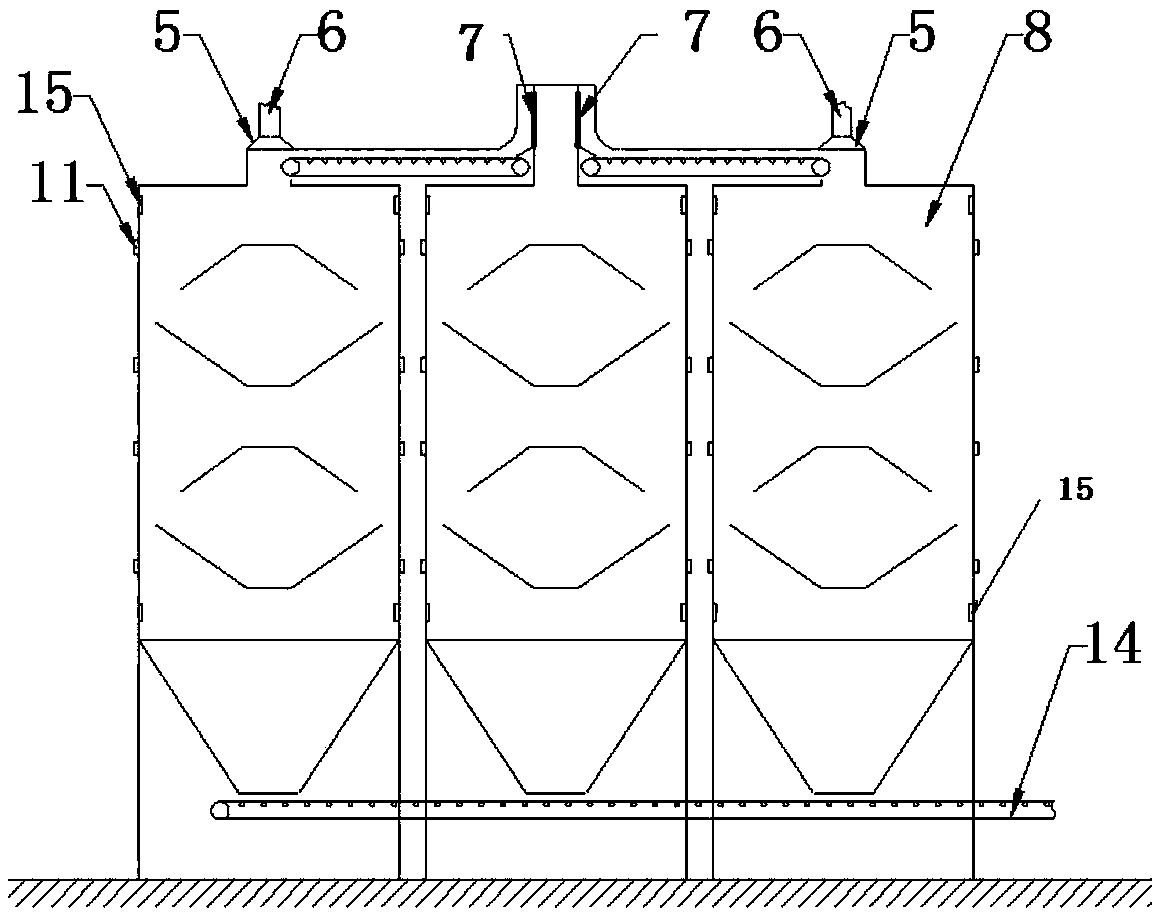

[0036] The present invention is further described below in conjunction with accompanying drawing:

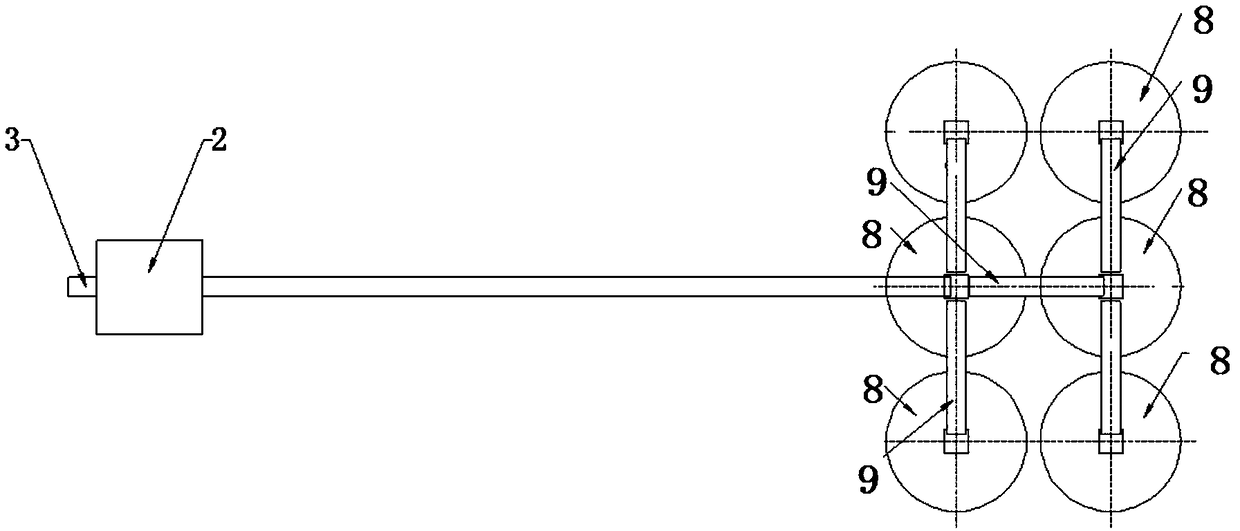

[0037] see Figure 1 to Figure 12 , a cold aggregate feeding and storage device for an asphalt mixing plant, including a feeding mechanism, an aggregate distribution device, a storage device and an aggregate buffer device; the aggregate distribution device is arranged at the top of the storage device, and one end of the feeding mechanism Connect the aggregate distribution device, the other end is set on the ground; the aggregate buffer device is set inside the storage device;

[0038] The material storage device includes several storage bins 8, and the aggregate distribution device includes a material guide conveyor 9, a sleeve, a connecting pipe and a flip door; the top of each storage bin 8 is vertically provided with a sleeve, and the sleeve and The interior of the storage bin 8 is connected; the sleeves are connected through connecting pipes, and each connecting pipe is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com