High-pressure spray dedusting system applied to soil restoration process

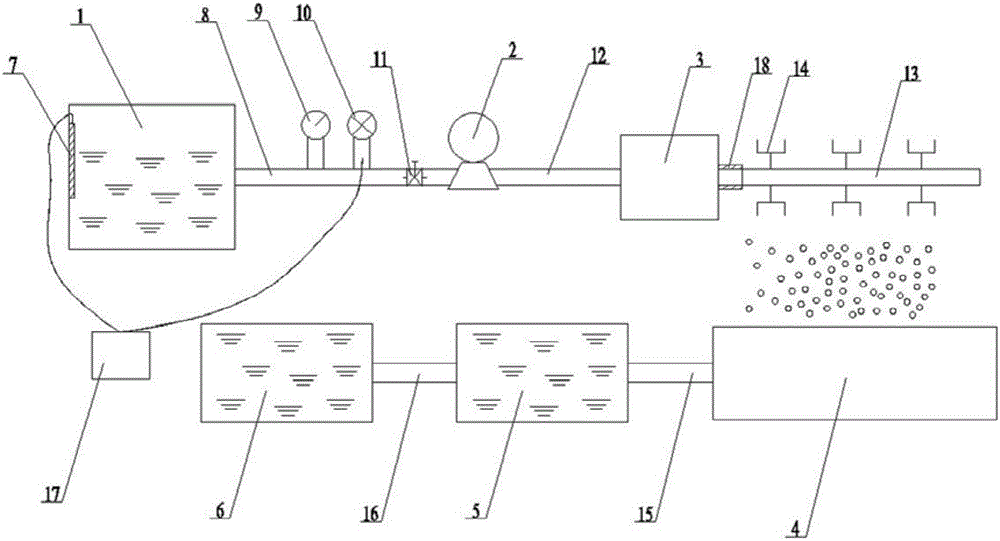

A technology of high-pressure spraying and dust removal system, which is applied in the direction of using liquid separation agent, separation of dispersed particles, chemical instruments and methods, etc. It can solve problems such as the treatment of soil dust, the physical and mental health hazards of construction workers, and the environmental impact of construction sites, etc. , to achieve the effect of improving the environmental problems of the construction work surface, a high degree of automation, and improving the efficiency of dust suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The dust particle concentration in a factory workshop is 100mg / m 3 , it is expected that the concentration of dust particles after dust fall will be 20mg / m 3 , The dust reduction rate can reach 80%.

[0019] 1) The aperture of atomizing nozzle 14 is 1.2mm, which requires a spray water pressure of 6MPa;

[0020] 2) The aperture of atomizing nozzle 14 is 1.5mm, which requires a spray water pressure of 4MPa;

[0021] 3) The water consumption of the atomizing nozzle 14 with an aperture of 1.2 mm is 5.0 L / min, and the water consumption of the atomizing nozzle 14 with an aperture of 1.5 mm is 6.5 L / min.

[0022] Although the atomizing nozzle 14 with an aperture of 1.5mm requires low pressure, the water consumption per unit time is 1.5L / min more for each atomizing nozzle 14 with an aperture of 1.5mm, consuming 25% more water resources.

[0023] (2) If the high-pressure water pump 2 can provide the amount of water to the spray system, each atomizing nozzle 14 has only 3L / min...

Embodiment 2

[0030] If the dust concentration is set to 5g / min and the roadway wind speed is 0.5m / s, the dust data concentration of the atomizing nozzle at the front and rear sections of the roadway spraying section at different pressures can be measured, and the dust drop rate at different pressures can be obtained according to the dust concentration efficiency data.

[0031] (1) For the same type of atomizing nozzle 14 and dust with a certain particle size distribution, the spray dust suppression efficiency under the wind speed of 0.5m / s increases with the increase of spray pressure, from 2MPa to 8MPa, and the dust dust suppression efficiency improves 21.32%, but when the atomization pressure increased from 8MPa to 10MPa, the dust reduction efficiency only increased by 1.79%.

[0032] When the spray pressure reaches a certain value, continue to increase the spray pressure, the improvement of the dust reduction efficiency is not obvious. Spray dust reduction is mainly carried out through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap