Capping device and method for iron mixing vehicle

A technology of mixed iron car and driving device, which is applied in the direction of metal processing equipment, manufacturing tools, casting molten material containers, etc., which can solve the problems of rapid drop in molten iron temperature, increase in steelmaking costs, and environmental pollution, etc., to reduce heat loss , increase the environmental protection index and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

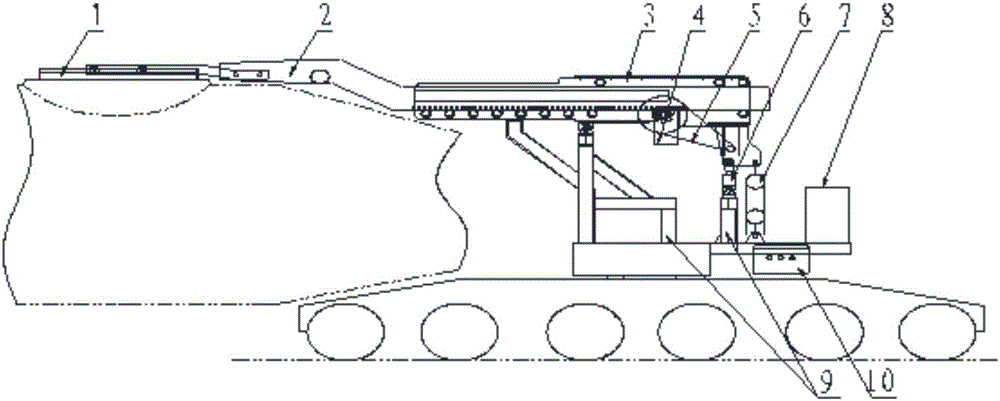

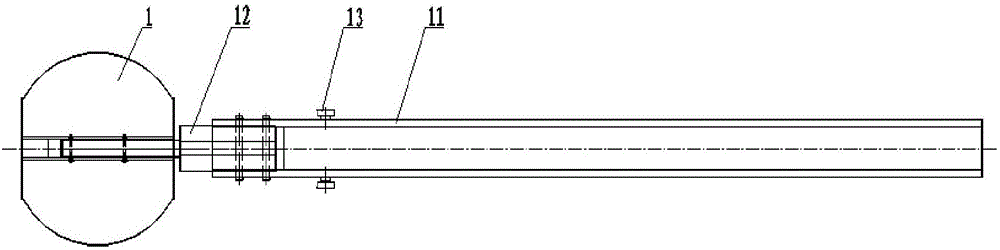

[0040] Such as Figure 1-Figure 4As shown, a capping device for a mixed iron car includes a tank cover 1, a traveling beam device 2, a rotating frame device 3, a driving device 4, a manual chain transmission device 5, a hydraulic cylinder 6, a chain hoist 7, and a hydraulic station 8 , steel structure 9 and electrical equipment 10.

[0041] The steel structure 9 is welded and fixed on the platform of the driven end, and the hydraulic station 8 and electrical equipment 10 are installed on the steel structure 9 .

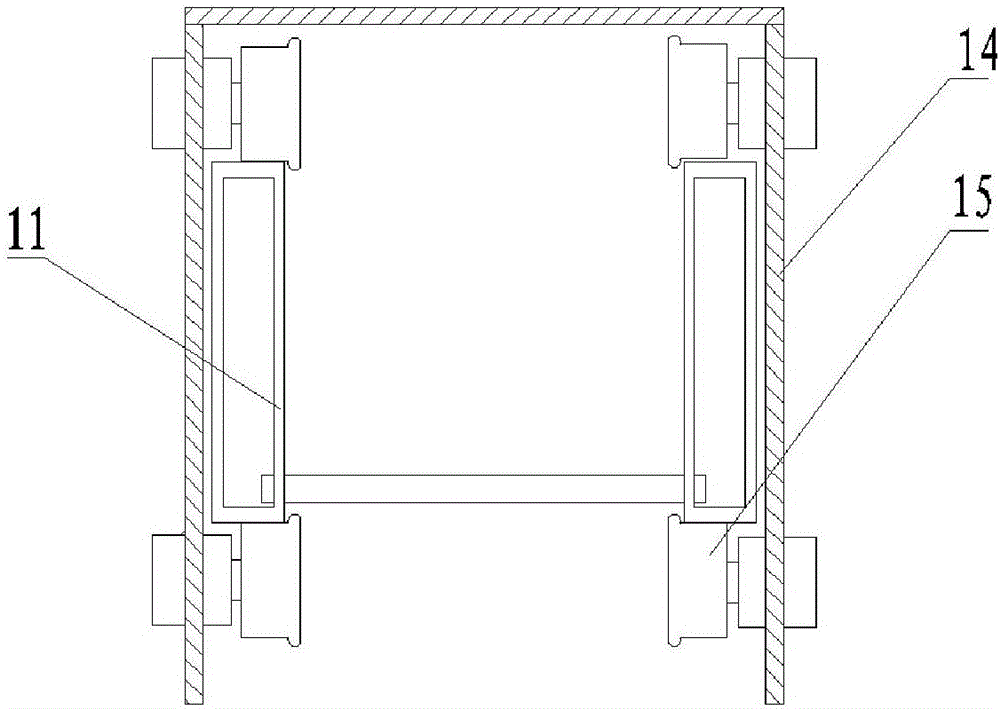

[0042] The rotating frame device 3 is installed on the steel structure 9 through the rotating shaft, so that the rotating frame device 3 can rotate relative to the steel structure 9 with the rotating shaft as the center after being stressed; image 3 As shown, the rotating frame device 3 includes a frame body 14 and rollers 15 regularly arranged on the top of the frame body 14; The frame body 14 advances and retreats on the rollers.

[0043] The traveling beam devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com