Gelatin wastewater treatment process beneficial to environmental protection

A technology for wastewater treatment and gelatin, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, and application. The effect of improving the firing efficiency, shortening the firing time, and improving the environmental protection index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

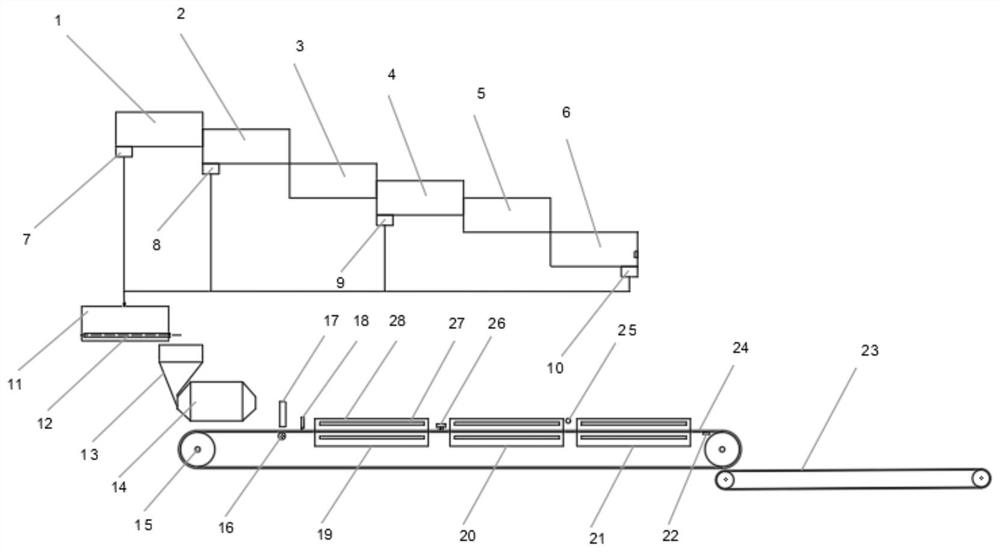

[0035] A kind of gelatin waste water treatment process that is conducive to environmental protection, comprises the following steps:

[0036] S1, the waste water is introduced into the pre-sedimentation tank 1, after natural quieting, the supernatant in the pre-sedimentation tank 1 is discharged into the regulating tank 2, and the sludge in the pre-sedimentation tank 1 is filtered by the first filter press 7, The filtered tail water returns to the pre-sedimentation tank 1, and the mud cake is discharged into the batching tank 11;

[0037] S2, the pH value of the wastewater in the regulating tank 2 is adjusted to 8.5 by adding concentrated sulfuric acid, the re-precipitated wastewater supernatant enters the flocculation reaction tank 3, and the re-precipitated sludge in the regulating tank 2 is processed by the second filter press 8 Pressure filtration, the tail water of the pressure filtration returns to the adjustment tank 2, and the mud cake is discharged into the batching t...

Embodiment 2

[0056] Parts not mentioned in this embodiment are as described in the foregoing embodiments.

[0057] In this example:

[0058] In step S2, the pH value of the wastewater in the regulating tank 2 is adjusted to 9.5, the re-precipitated wastewater supernatant enters the flocculation reaction tank 3, and the re-sedimented sludge in the regulating tank 2 is filtered through the second filter press 8 , the press-filtered tail water returns to the adjustment tank 2, and the mud cake is discharged into the batching tank 11;

[0059] In step S5, the batching weight ratio in the batching tank 11 is mud cake: coal gangue=25:1, and the moisture content of the mud cake is 70%;

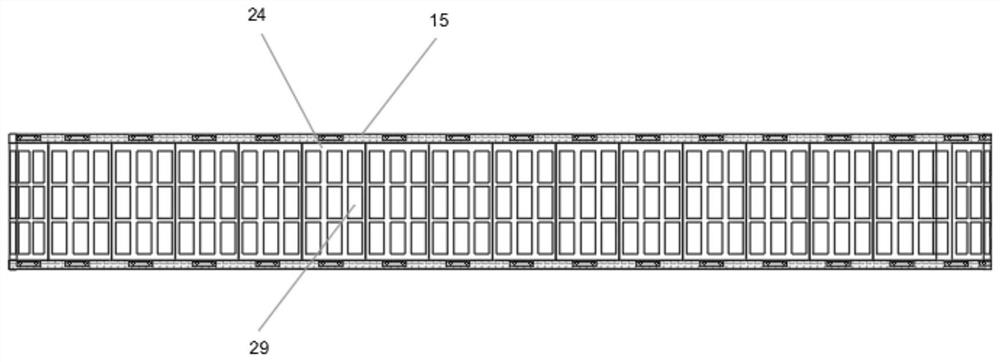

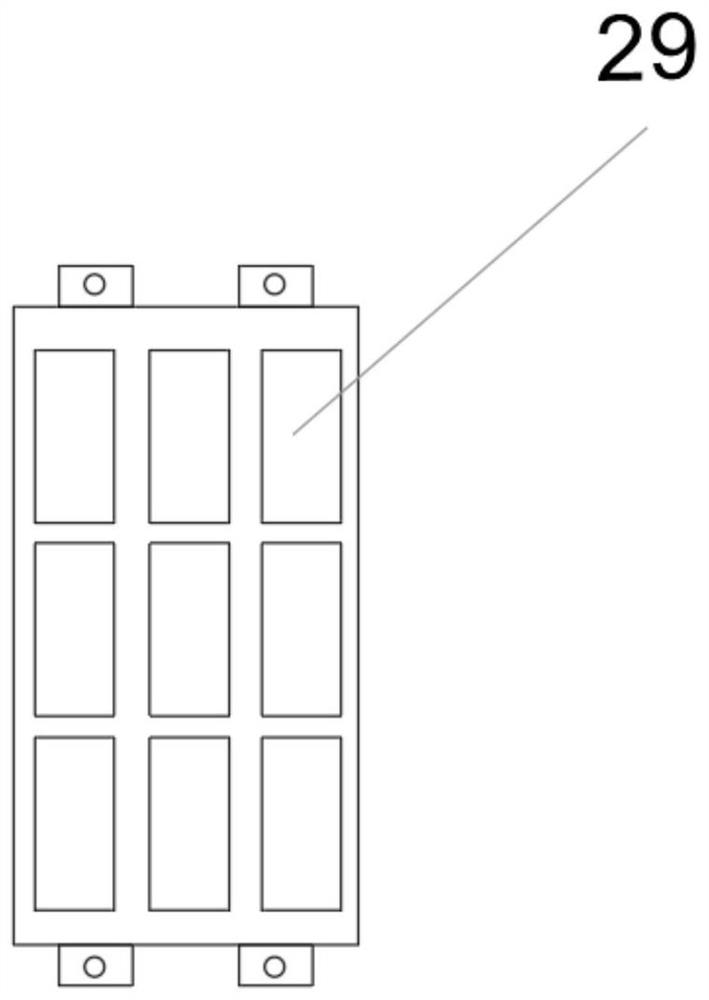

[0060] In step S7, the fixed mold car 24 enters the first drying section 19, the baking temperature is 40°C, and the baking time is 15 minutes;

[0061] In step S9, enter the second drying section 20 for baking, the baking temperature is 60°C, and the baking time is 10 minutes;

[0062] In step S11, enter the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com