Automatic processing and conveying line for pipe fittings

An automatic processing and assembly line technology, applied in the direction of tubular goods, recycling technology, other household appliances, etc., can solve the problems of high labor intensity, high labor cost and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

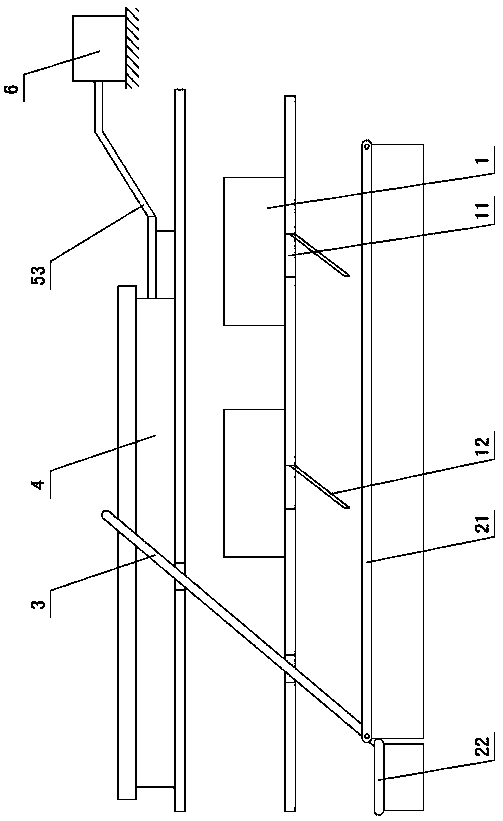

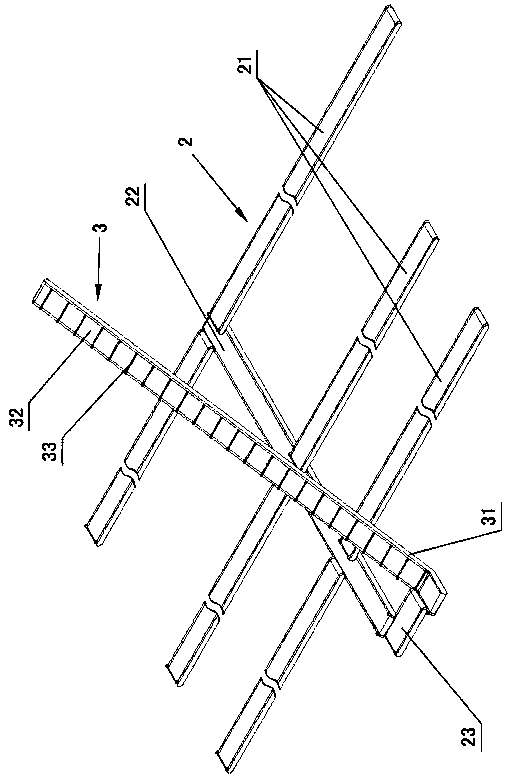

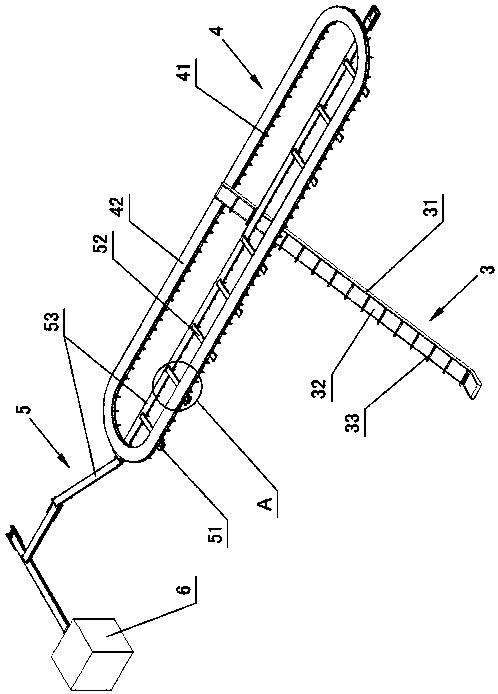

[0012] The invention relates to an automatic processing and conveying line for pipe fittings, such as figure 1 — Figure 5 As shown, it is characterized in that it includes an injection molding machine 1, a collection conveying mechanism 2 under the pipe fittings, a large-span ramp conveying mechanism 3, an upper conveying integrated turntable 4 for the pipe fittings, and a plastic port conveying mechanism 5. There is a blanking hole 11 on the ground, and an inclined feeding hopper 12 is arranged under the blanking hole. The feeding hopper corresponds to the collective conveying mechanism 2 under the pipe fittings. and the guide conveyor belt 23, the branch conveyor belt is higher than the aggregate conveyor belt, the aggregate conveyor belt is higher than the guide conveyor belt, the feeding hopper 12 corresponds to the branch conveyor belt 21, and the tail outlet of each branch conveyor belt corresponds to the aggregate conveyor belt 22 , the tail outlet of the aggregated c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com