Moisture absorption type high-barrier blister packaging rigid sheet

A blister packaging, high-barrier technology, applied in the field of pharmaceutical packaging materials, can solve problems such as infiltration, inability to reduce moisture, etc., and achieve the effect of improving the quality assurance function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

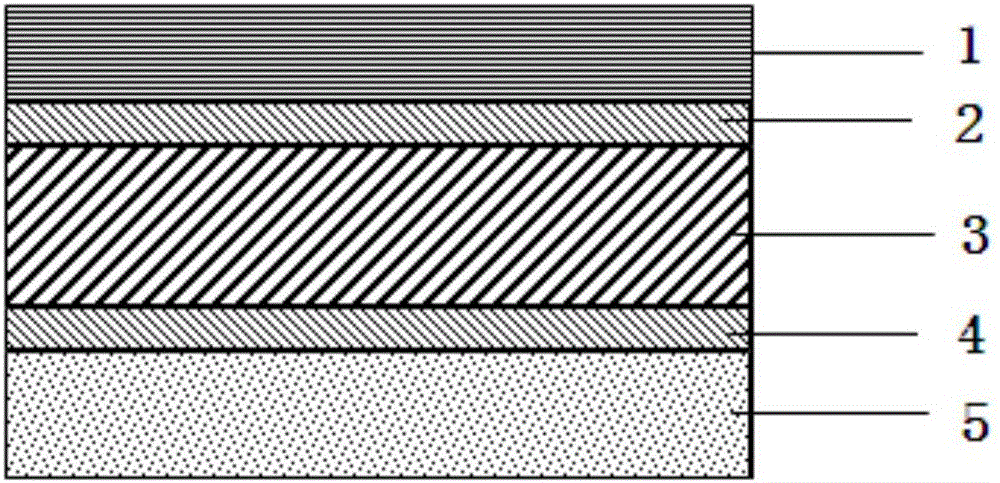

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0023] Such as figure 1 As shown, this case lists a hygroscopic high-barrier blister packaging hard sheet of an embodiment, which is provided with: polychlorotrifluoroethylene layer 1, first polyurethane adhesive layer 2, polyvinyl chloride layer in sequence from top to bottom 3. The second polyurethane adhesive layer 4 and the hygroscopic film layer 5 .

[0024] Among them, the thickness of the polytrifluorochloroethylene layer 1 is preferably 15-102 μm.

[0025] Among them, the thickness of the polyvinyl chloride layer 3 is preferably 60-200 μm.

[0026] Among them, the thickness of the hygroscopic film layer 5 is preferably 50-100 μm.

[0027] Wherein, the hygroscopic film layer 5 includes polyethylene and a modifying agent.

[0028] As another embodiment of the case, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com