Methods and system for shifting a hybrid vehicle

The technology of a transmission system and operation method is applied to hybrid vehicles, the layout of multiple different prime movers of general power plants, motor vehicles, etc., which can solve the problems of transmission system efficiency reduction, motor range reduction, etc., and achieve improved vehicle performance. The effect of energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

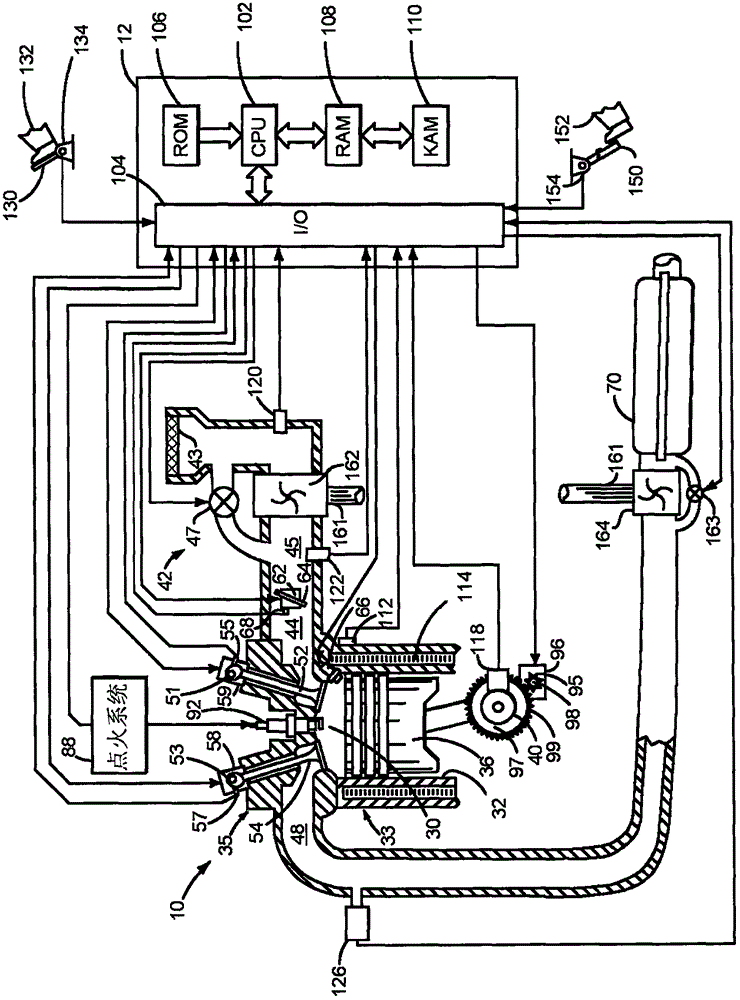

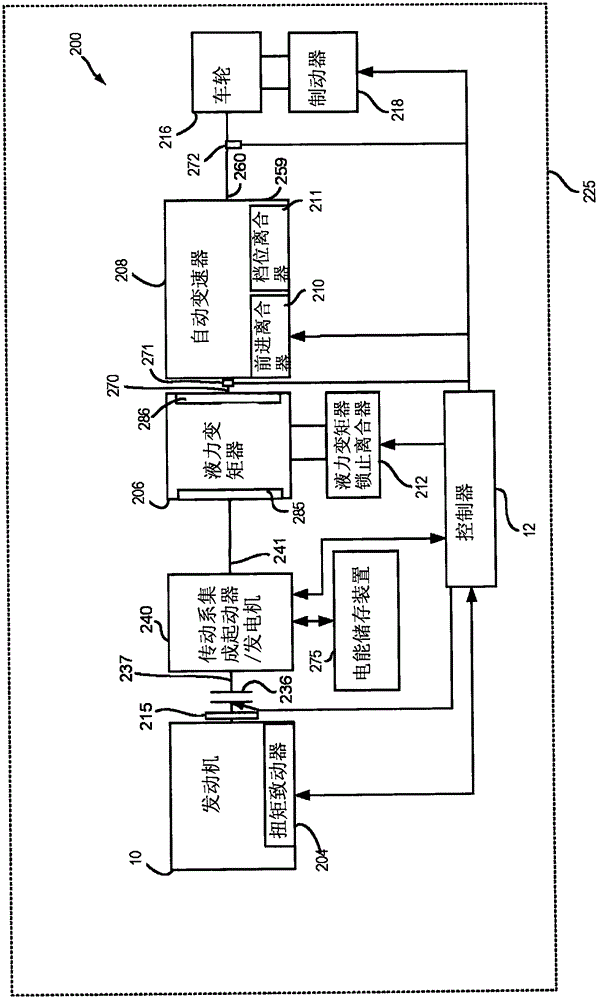

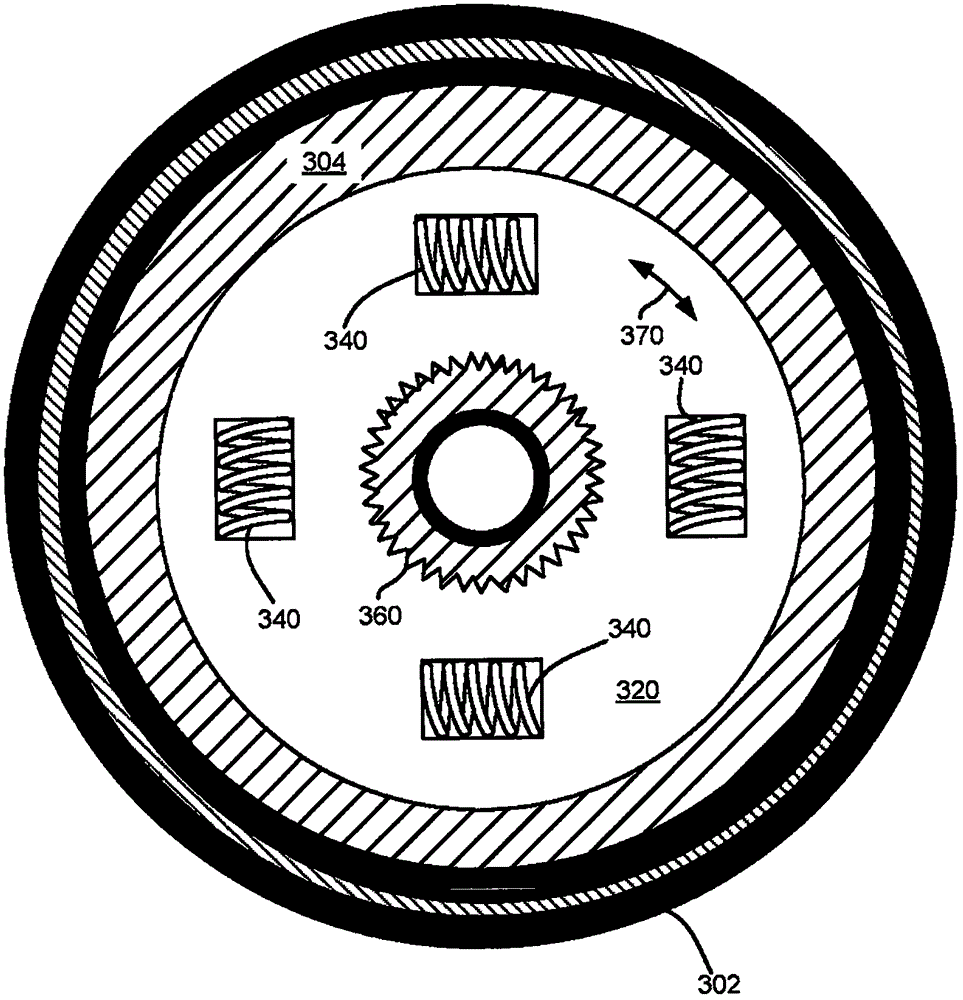

[0028] This specification relates to controlling the driveline of a hybrid vehicle during gear changes. Hybrid vehicles can include figure 1 engine shown. figure 1 The engine can be included in the figure 2 in the drivetrain or driveline shown. The drive train can include such as Figure 3A and Figure 3B Torque converter clutch or lockup clutch shown with or without damper spring. The drive train can include based on Figure 4 and Figure 5 Block diagram controls. The drive train can be Figure 6 shown method to operate.

[0029] refer to figure 1 , the internal combustion engine 10 comprises a plurality of cylinders, at figure 1 One of a plurality of cylinders is shown in , and the internal combustion engine 10 is controlled by an electronic engine controller 12 . Engine 10 is comprised of cylinder head 35 and cylinder block 33 including combustion chamber 30 and cylinder walls 32 . Piston 36 is positioned within cylinder wall 32 and reciprocates by being conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com