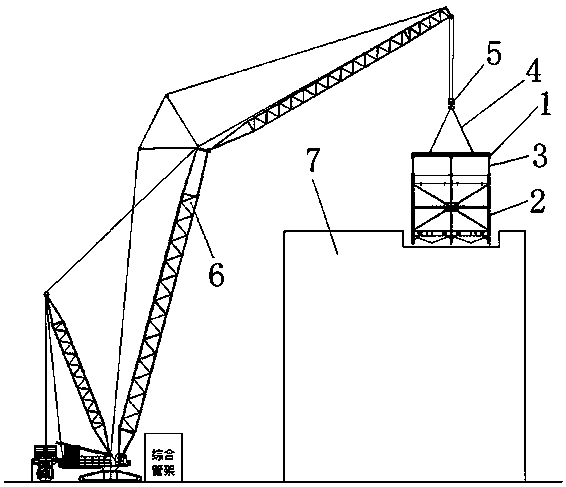

A method for overall hoisting of wet electrostatic precipitator body equipment

A wet electrostatic precipitator and integral hoisting technology, which is applied to cranes and other directions, can solve the problems of high installation requirements of wet electrostatic precipitator body equipment and inapplicability to the overall hoisting of wet electrostatic precipitator body equipment, etc., so as to shorten the construction period and prevent equipment deformation. , reduce the effect of high-altitude work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

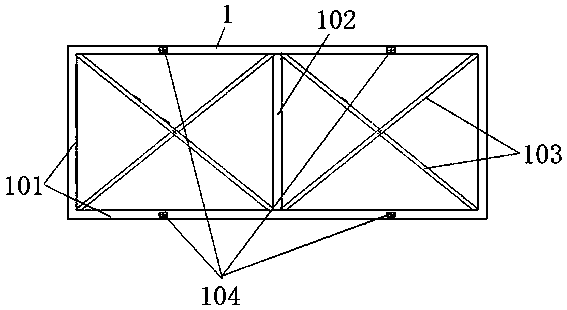

[0043] by attaching figure 1 It can be seen that the present invention relates to an auxiliary suspension beam for overall hoisting of the wet electrostatic precipitator body equipment, which is a rectangular frame structure matched with the wet electrostatic precipitator main body equipment, including a rectangular frame 101, and the rectangular frame 101 and the wet electrostatic precipitator The size of the top of the 6 columns of the main body equipment is matched, a reinforcing rib 103 is provided in the frame 101, an upper lug 104 connected with the lifting device is provided on the upper end surface of the rectangular frame 101, and a The lower lifting lug 105 connected with the main body equipment of the wet electrostatic precipitator.

[0044] The auxiliary hanging beam 1 is rectangular, and there is an auxiliary beam 102 in the middle, forming a "day"-shaped structure; the four corners and the middle position of the auxiliary hanging beam "day"-shaped structure are r...

Embodiment 2

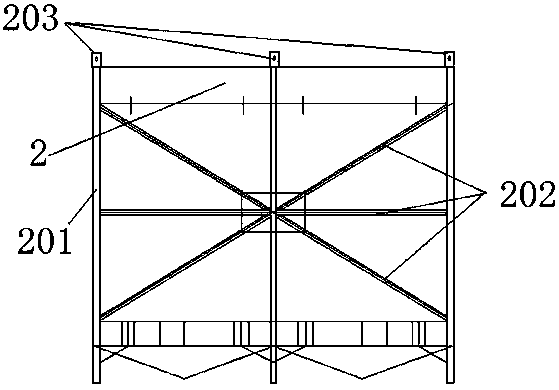

[0059] The basic principle of the second embodiment is the same as that of the first embodiment, but the structure is different. It is a kind of auxiliary suspension beam for integral hoisting of the main body equipment of the wet electrostatic precipitator, which is a rectangular frame structure matched with the main equipment of the wet electrostatic precipitator, including rectangular Frame, the rectangular frame matches the size of the top of the 6 pillars of the wet electrostatic precipitator body equipment, there are reinforcing ribs in the frame, and the upper end of the rectangular frame is provided with upper lugs connected with the lifting equipment. The upper end surface of the frame is provided with lower lifting lugs connected with the main body equipment of the wet electrostatic precipitator.

[0060] The auxiliary hanging beam is rectangular, and there is an auxiliary beam in the middle, forming a "day"-shaped structure; the four corners and the middle position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com