Preparation method of bispyranthiophene photochromic polymer and color-changing anti-counterfeiting ink

A technology of bispyranthia and anti-counterfeiting inks, which can be applied in inks, applications, household appliances, etc., can solve the problems of limiting the application range and service life of color-changing compounds, poor fatigue resistance, and slow color-changing speed, so that the light-changing ability will not be weakened , not easy to yellow, the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

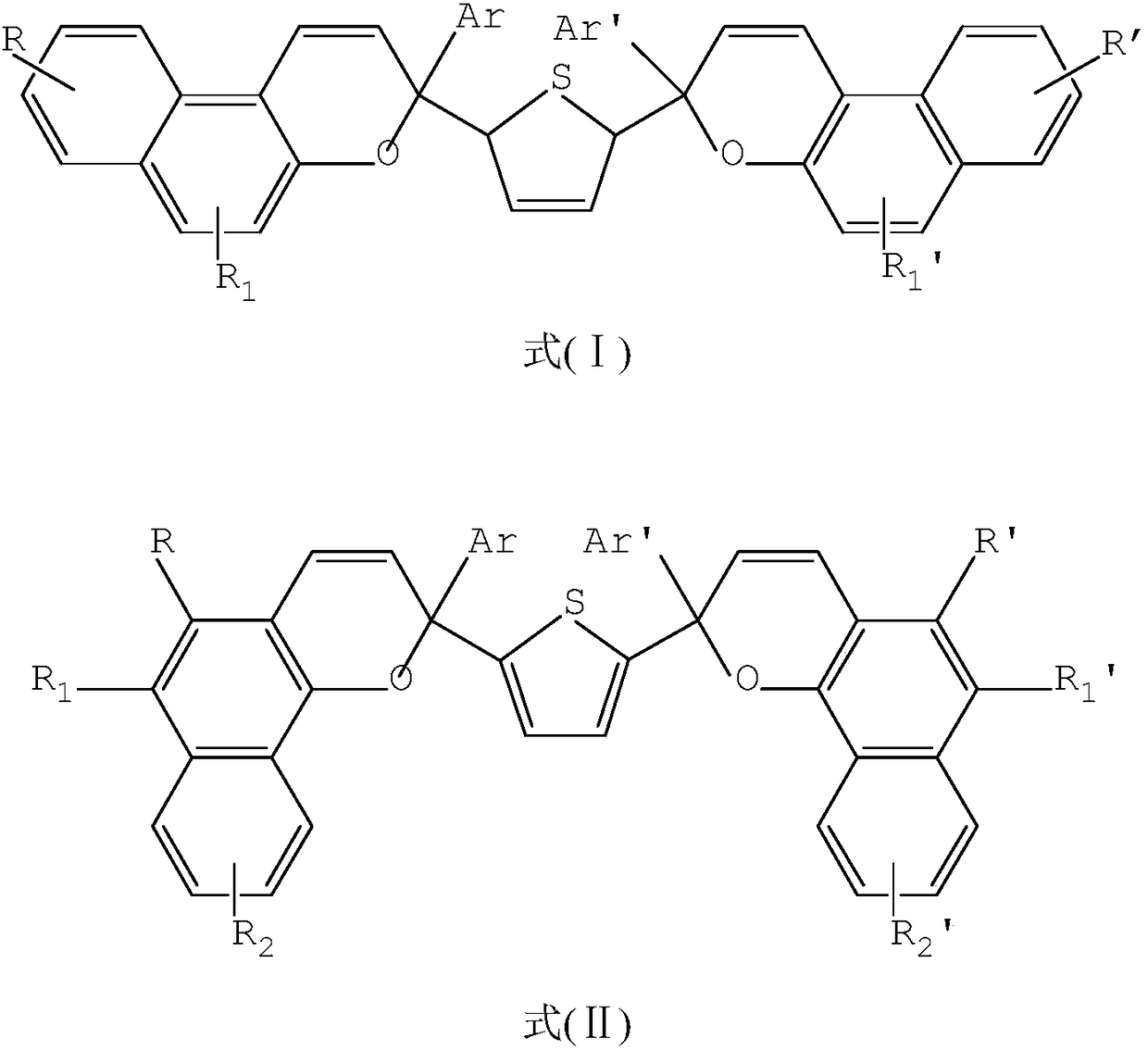

Method used

Image

Examples

preparation example Construction

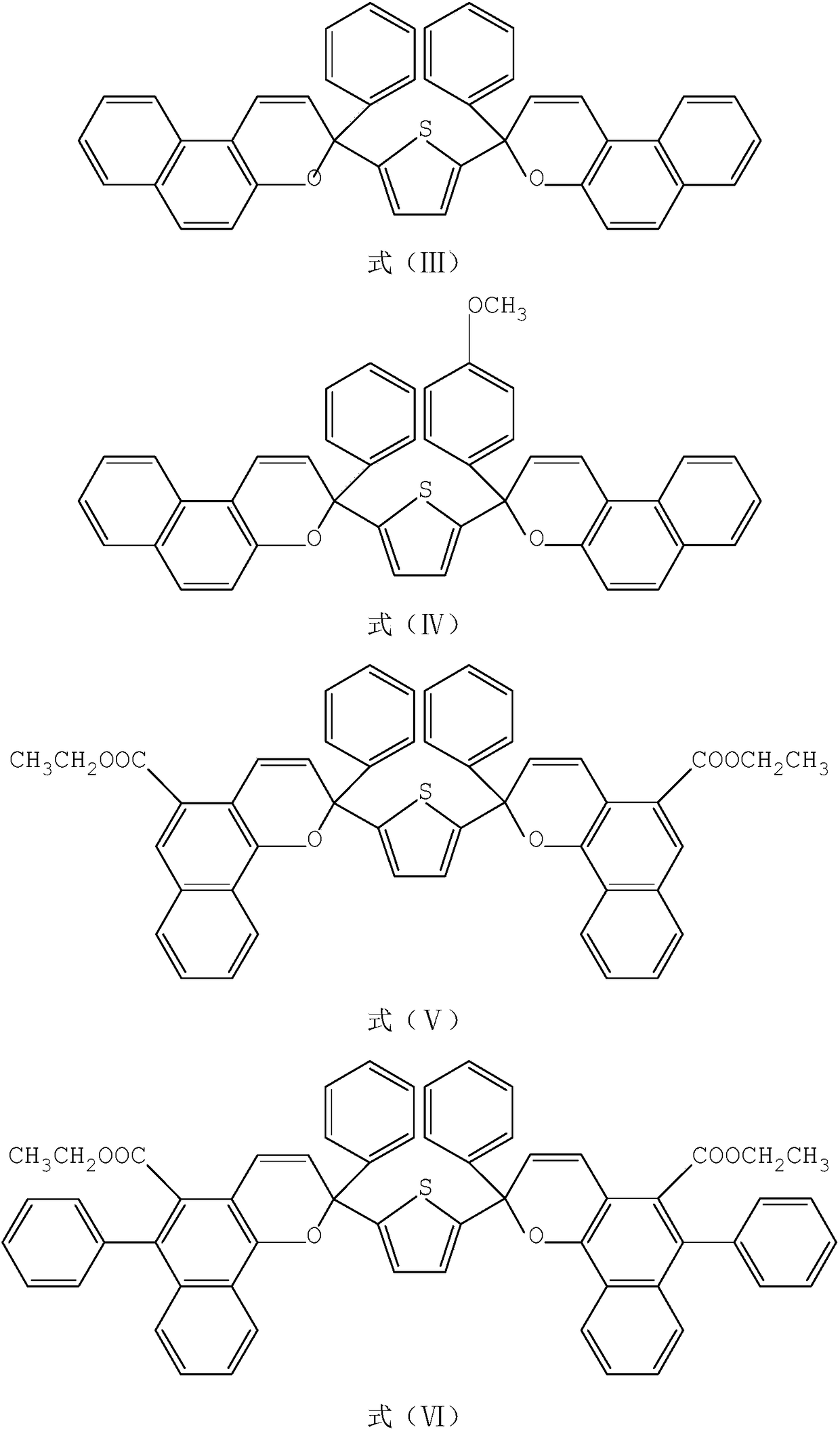

[0042] The preparation of the photochromic dye of the present invention refers to the existing technology (Xiuhong Lu, Qian Dong, Xiaochun Dong, Weili Zhao, Synthesis and sequential photochromism of thiophene-linkedbis-pyrans. Tetrahedron 71 (2015) 4061-4069).

[0043] In Examples 1-4, the bispyranthiophene photochromic dye used was prepared by the following method:

[0044] S1. Under an ice-water bath, add 10mmol thiophene, dichloroethane, and 3-8mmol tin tetrachloride into the reaction kettle in turn, stir evenly, and slowly add 20-22mmol benzoyl chloride or alkoxybenzoyl chloride within 30min , reacted for 48h, rotary steamed and purified;

[0045] S2. Dissolve the product of step S1 in 3-10ml tetrahydrofuran, pass N 2 , under an ice-water bath, add 35-45 mmol of trimethylsilylacetylene and 20-35 mmol of n-butyllithium to react for 8 hours;

[0046] S3. At room temperature, slowly add 30-40 mmol tetrabutylammonium fluoride tetrahydrofuran solution dropwise, react for 20-30 ...

Embodiment 1

[0055] S1. Dissolve 10mmol bispyranothiophene photochromic dye A and 18-22mmol acetyl chloride in 60-80mL nitrobenzene, slowly add 28-32mmol aluminum trichloride dropwise, and react at room temperature for 4-8 hours; Acetyl bis-pyranothiophene photochromic dye;

[0056] S2. Dissolve 8 mmol of the product in step S1 in 25-30 mL of dioxane, add dropwise 0.15-0.2 mmol of sodium hypochlorite dissolved in 15-20 mL of dioxane at 50°C, and react at 70-80°C for 2-3 hours; Purified to obtain the photochromic dye of bispyranothiophene with carboxyl groups;

[0057] S3. Dissolve 5 mmol of the product in step S2 in 20 to 30 mL of dichloromethane, add 5 to 6 mmol of hydroxyethyl methacrylate, 5 to 7 mmol of dicyclohexylcarbodiimide, and 0.2 to 0.6 mmol of catalyst 4-dimethylamino Pyridine, reacted at room temperature for 5-8 hours; purified to obtain bis-pyranothiophene photochromic dye with double bond;

[0058] S4.N 2 Under protection, blend 11.5g of the product of step S3 with 29.5g ...

Embodiment 2

[0062] The bispyranothiophene photochromic dye A described in Example 1 was replaced with the bispyranothiophene photochromic dye B, and the bispyranothiophene photochromic dye with a double bond was prepared according to the method described in S1 to S3 in Example 1 dye;

[0063] S4.N 2 Under protection, blend 5g of the product of step S3 with 36g of butyl acrylate, 8g of methyl methacrylate, 1g of acrylic acid, and 49.8g of tetrahydrofuran, raise the temperature to 50°C, add 0.2g of the initiator azobisisoheptanonitrile, and react for 5h , and the solvent was removed by rotary evaporation to obtain bis-thiopyranophotochromic polymer 2.

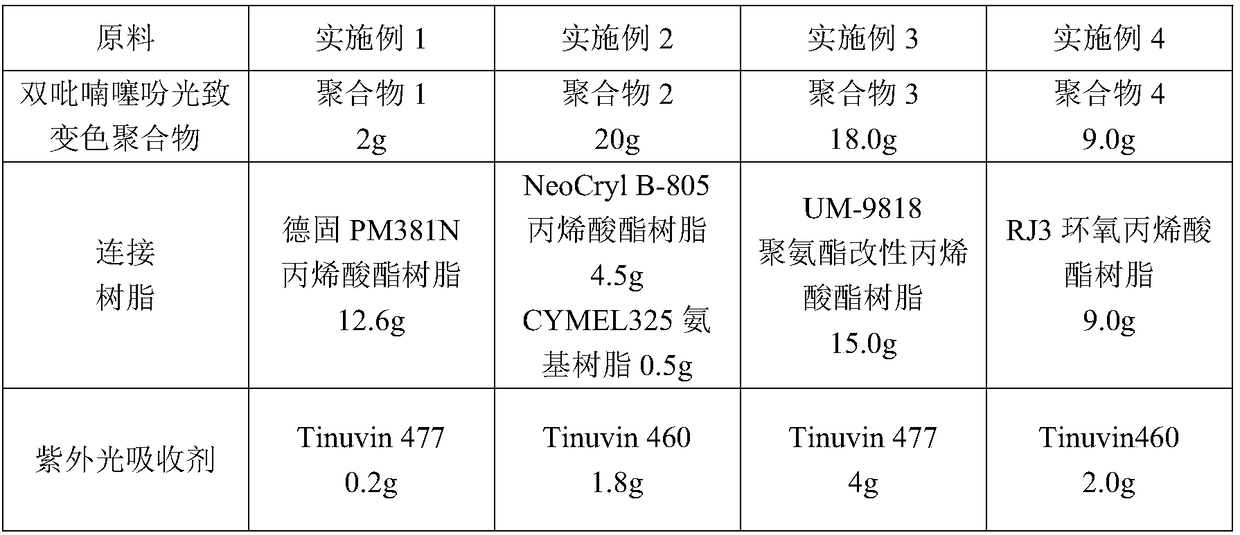

[0064] Dissolve the linking resin in xylene, dissolve the bispyranothiophene photochromic polymer 2 in xylene, mix, add UV absorber, hindered amine stabilizer and antioxidant dissolved in butyl acetate, and stir After uniformity, the photochromic anti-counterfeiting ink is obtained. See Table 1 for specific models and dosages.

[0065] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com