Method for extracting peel pigment from green plums

An extraction method and peel technology, which is applied in the field of extraction of greengage peel pigment, can solve the problems of low extraction rate of greengage peel pigment, dark color of greengage peel pigment, unfavorable promotion and application, etc., to improve water migration conditions, protect color, shorten Effect of drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

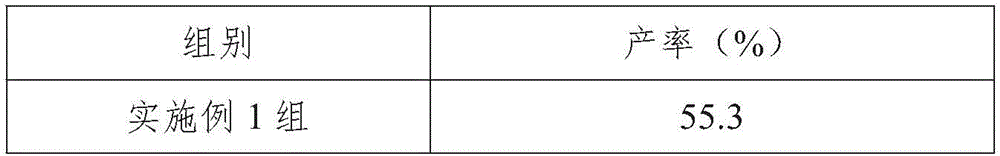

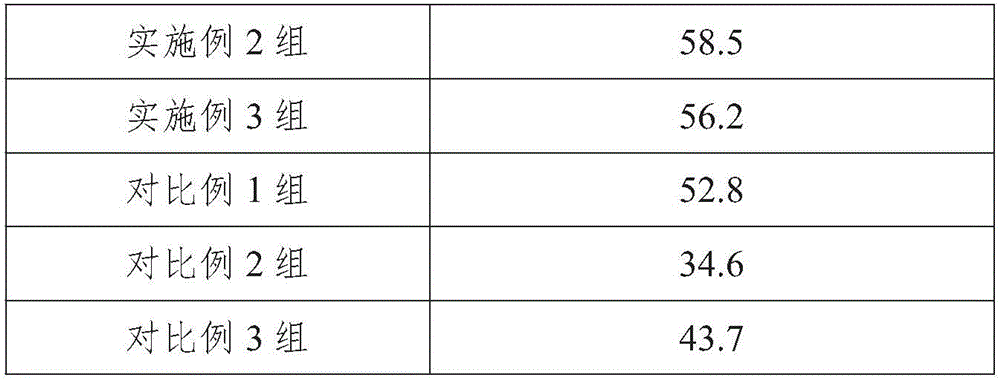

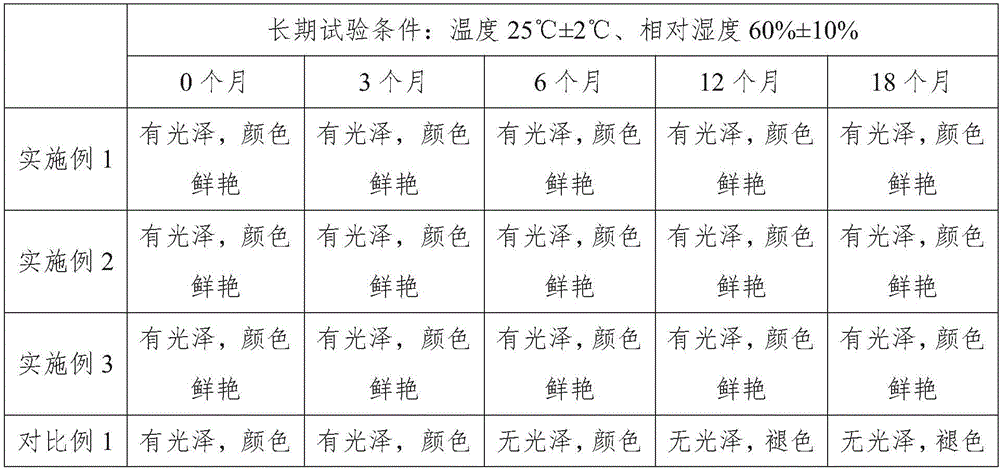

Examples

Embodiment 1

[0028] Embodiment 1, the preparation of green plum peel pigment

[0029] S1 Dry the clean greengage peel with microwave for 8 minutes, the microwave drying power is 420W, pulverize, pass through 100 mesh, and obtain fine powder;

[0030] S2 Add the fine powder obtained in step S1 into an organic solvent with a mass concentration of 65%. The organic solvent is composed of acetol and dodecyl glucoside in a volume ratio of 4:2, and the solid-liquid ratio is 1g:16ml. Ultrasonic Extract twice, the extraction temperature is 45°C, the extraction time is 2h, filter, and combine the filtrates to obtain the extract;

[0031] S3 Centrifuge the extract obtained in step S2 for 15 min at a rotational speed of 5000 r / min, take the supernatant, and filter it with a mixed cellulose ester membrane with a pore size of 0.45 μm to obtain a filtrate;

[0032] S4 freeze-concentrates the filtrate obtained in step S3, the freeze-concentration adopts suspension type freeze-concentration, and the condi...

Embodiment 2

[0033] Embodiment 2, the preparation of green plum peel pigment

[0034] S1 Dry the clean greengage peel by microwave for 10 minutes, the microwave drying power is 435W, pulverize, pass through 120 mesh, and obtain fine powder;

[0035] S2 Add the fine powder obtained in step S1 into an organic solvent with a mass concentration of 72%. The organic solvent is composed of acetol and dodecyl glucoside in a volume ratio of 5:1.5, and the solid-liquid ratio is 1g:18ml. Ultrasonic Extract twice, the extraction temperature is 50°C, the extraction time is 2h, filter, and combine the filtrates to obtain the extract;

[0036] S3 Centrifuge the extract obtained in step S2 for 12 minutes at a speed of 6000 r / min, take the supernatant, and filter it with a mixed cellulose ester membrane with a pore size of 0.50 μm to obtain a filtrate;

[0037] S4 freeze-concentrates the filtrate obtained in step S3, the freeze-concentration adopts suspension type freeze-concentration, and the conditions ...

Embodiment 3

[0038] Embodiment 3, the preparation of green plum peel pigment

[0039] S1 Dry the clean greengage peel by microwave for 12 minutes, the microwave drying power is 450W, pulverize, pass through 140 mesh, and obtain fine powder;

[0040]S2 Add the fine powder obtained in step S1 into an organic solvent with a mass concentration of 75%. The organic solvent is composed of acetol and dodecyl glucoside in a volume ratio of 6:1, and the solid-liquid ratio is 1g:20ml. Ultrasonic Extract twice, the extraction temperature is 55°C, the extraction time is 3h, filter, and combine the filtrates to obtain the extract;

[0041] S3 Centrifuge the extract obtained in step S2 for 10 min at a rotational speed of 8000 r / min, take the supernatant, and filter it with a mixed cellulose ester membrane with a pore size of 0.55 μm to obtain a filtrate;

[0042] S4 freeze-concentrates the filtrate obtained in step S3, the freeze-concentration adopts suspension type freeze-concentration, the conditions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com