Vacuum microwave vibration drying method with low energy consumption and low crack ratio for granular food-borne material

A drying method and granular technology, which is applied in the field of processing and preservation of food-derived materials, can solve the problems of high energy consumption and high drying cost, and achieve the effects of uniform drying, reduced drying energy consumption, and sensitive response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

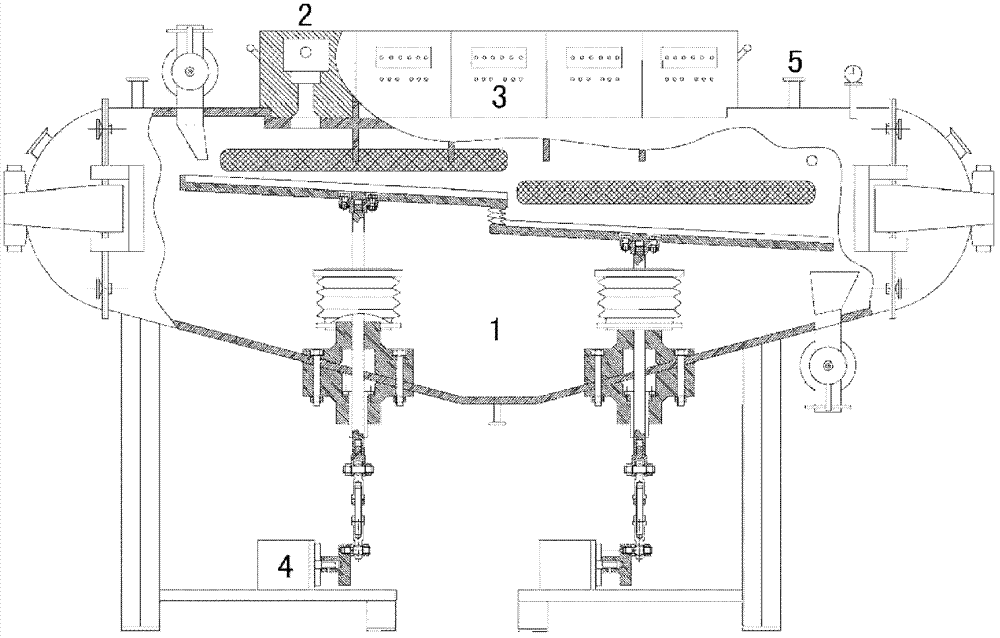

Method used

Image

Examples

Embodiment 1

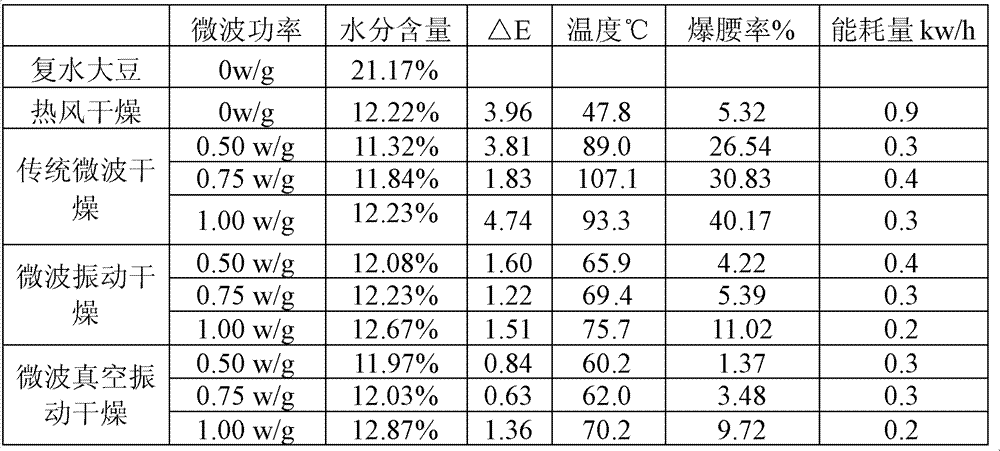

[0054] The hot air drying method of rehydrated soybeans and the traditional microwave drying method at different powers (0.50w / g, 0.75w / g, 0.10w / g):

[0055] Weigh 200g of pretreated complete soybeans, place them in a drying room container, and heat them with 0.50w / g, 0.75w / g, and 0.10w / g microwave power for 30min, 20min, and 12min respectively, and turn on the air dehumidification system , the temperature is controlled at 4-10°C, after the drying is completed, cool down, take a sample to measure the moisture, color, temperature and burst rate, and record the number of the meter. (See Table 2)

Embodiment 2

[0057] Microwave vacuum vibration bed drying method for rehydrated soybeans at different powers (0.50w / g, 0.75w / g, 0.10w / g):

[0058] Weigh 200g of pretreated complete soybeans and put them into a polytetrafluoroethylene tank, the tank weight is 2426.5g, and the tank wall thickness is 2.4cm. After placing the container in the drying room, vacuumize to -0.065MPa, and use 100w, 150w, and 200w microwave power respectively. Heating, the vibration frequency of the motor is 450r / min; the set running time is 1.3s, and the intermittent time is 1s as a vibration cycle; the heating time is 30min, 20min, and 12min respectively, and the air dehumidification system is turned on, the temperature is controlled at 4-10°C, and the drying is completed After cooling, take samples to measure moisture, color, temperature and bursting rate, and record the meter numbers.

[0059] Weigh 200g of pretreated whole kidney beans, put them into a polytetrafluoroethylene tank, place them in an oven, set the...

Embodiment 3

[0063] Drying method of rehydrated soybeans in a microwave vacuum vibrating bed at a microwave power of 0.50W / g and different vibration frequencies (350r / min; 450r / min; 550r / min):

[0064] Weigh 200g of pretreated complete soybeans and put them into a polytetrafluoroethylene tank, place them in a drying room container and then evacuate to -0.065MPa, set the microwave power to 0.5W / g; use motor vibration frequencies of 350r / min, 450r / min, Heating at 550r / min; set the running time to 1.3s, and the intermittent time to 1s as a vibration cycle; the heating time is 30min; turn on the air dehumidification system, and control the temperature at 4-10°C. After drying, cool down and take samples for moisture, Determination of color, temperature and bursting rate, and record the meter numbers.

[0065] Table 3. Effects of different motor vibration frequencies on drying materials by microwave vacuum vibrating bed drying method at microwave power of 0.5W / g

[0066]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com