Microwave vibration bed drying method of medium moisture content granular grains

A technology of microwave vibration and drying method, which is applied in the direction of saving seeds through drying, which can solve the problems of high energy consumption and high drying cost, and achieve the effect of low energy consumption, fast heating speed and automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

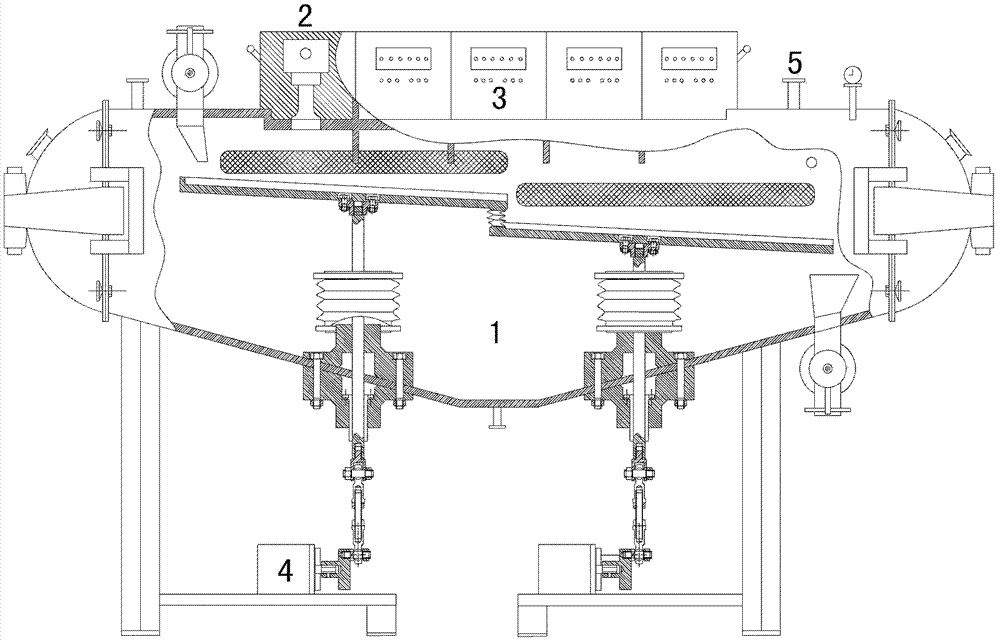

Image

Examples

Embodiment 1

[0045] Traditional microwave drying methods for rehydrated soybeans at different power levels (0.25w / g, 0.5w / g, 0.75w / g):

[0046] Weigh 200g of pretreated complete soybeans, place them in a container in a drying room, and heat them with 50w / g, 100w / g, and 150w / g microwave power for 50min, 35min, and 20min, respectively. Turn on the air dehumidification system and control the temperature At 4-10°C, after drying, cool down, take samples to measure moisture, color, temperature and burst rate, and record the numbers on the electric meter.

Embodiment 2

[0048] Microwave vibration bed drying method for rehydrated soybeans at different powers (0.25w / g, 0.5w / g, 0.75w / g):

[0049] Weigh 200g of pretreated complete soybeans, place them in a container in a drying room, and heat them with microwave power of 50w / g, 100w / g, and 150w / g respectively, and the vibration frequency of the motor is 250r / min; set the running time to 1.3s, and the intermittent time to 1s As a vibration cycle; the heating time is 50min, 35min, and 20min respectively. Turn on the air dehumidification system and control the temperature at 4-10°C. Record the meter numbers.

[0050] Table 2 Effect of traditional microwave drying and microwave vibrating bed drying methods on drying materials at different powers

[0051]

Embodiment 3

[0053] The microwave vibration bed drying method for rehydrated soybeans at a microwave power of 0.5W / g and different vibration frequencies (250r / min; 350r / min; 450r / min):

[0054] Weigh 200g of pretreated complete soybeans, place them in a drying room container, set the microwave power to 0.5W / g; use motor vibration frequencies of 250r / min, 350r / min, and 450r / min to heat respectively; set the operating time to 1.3s, intermittent The time is 1s as a vibration cycle; the heating time is 30min; the air dehumidification system is turned on, the temperature is controlled at 4-10°C, after the drying is completed, cool down, take samples to measure the moisture, color, temperature and bursting rate, and record the meter data .

[0055] Table 3 The influence of microwave vibration bed drying method on drying materials under different motor vibration frequencies under the microwave power of 0.5W / g

[0056]

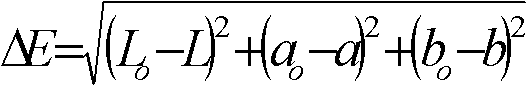

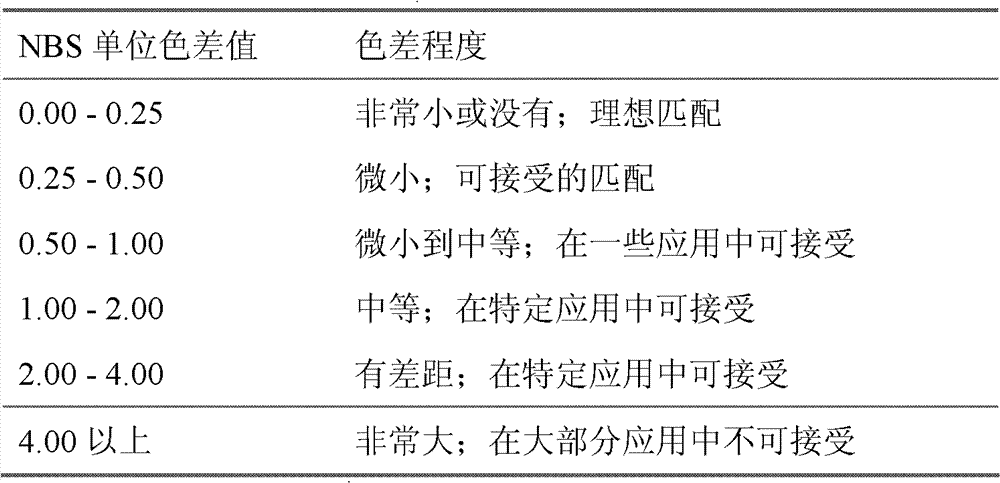

[0057] From the results of Table 2 and Table 3, it can be drawn that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com