Method for preparing fabric through inkjet and discharge printing

A discharge printing and fabric technology, applied in the field of inkjet discharge printing fabric preparation, can solve the problems of slurry water pollution, cumbersome process, etc., and achieve the effect of improving utilization rate, simple operation, and strong color contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

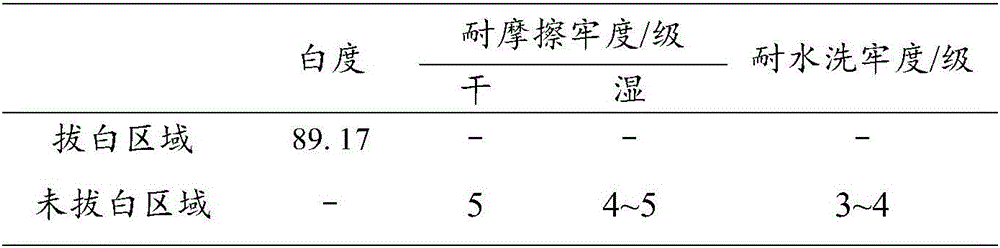

Embodiment 1

[0029] The formula of the sizing agent is as follows in terms of weight percentage: 0.5% sodium alginate is used as a thickener, 6% urea is used as a moisture absorbing agent, 1% sodium bicarbonate is used as an acid-base agent, and water is added to make up to 100%. Stir fully until the sodium alginate is fully swollen, and all components are completely dissolved and evenly dispersed. The dyed silk fabric is padded with sizing solution and then dried, and the fabric is sprayed with white ink by an inkjet printer, and dried at room temperature. Then steaming is carried out, the steaming temperature is 100° C., the steam saturation is 98%, and the time is 10 minutes. After the steaming is completed, the fabric is washed with water to obtain the ink-jet discharge printed fabric. After testing, the whitening area: the whiteness is 89.17; the non-whitening area: the dry rubbing fastness can reach grade 5, the wet rubbing fastness can reach grade 4-5, and the washing fastness can ...

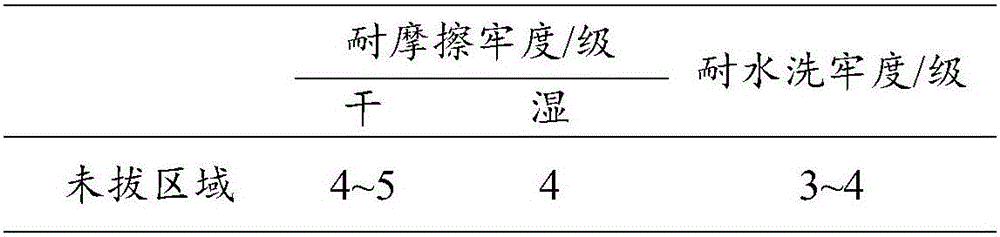

Embodiment 2

[0038] The formula of the sizing agent is as follows: the thickener is 2% sodium carboxymethyl cellulose, the hygroscopic agent is 8% urea, the acid-base agent is 2% sodium bicarbonate, and water is added to make up to 100%. Stir fully until the sodium alginate is fully swollen, and all components are completely dissolved and evenly dispersed.

[0039] The dyed cotton fabric is dried after padding with sizing solution, and the fabric is sprayed with white ink by an inkjet printer, and dried at room temperature. Then carry out steaming, the steaming temperature is 102° C., the steam saturation is 98%, and the time is 12 minutes. After the steaming is completed, the fabric is washed with water to obtain the ink-jet discharge printed fabric. After testing, the undrawn area: the dry rubbing fastness can reach 4~5 grades, the wet rubbing fastness can reach 4 grades, and the washing fastness can reach 3~4 grades. The test results are shown in Table 2.

[0040] Table 2 inkjet disc...

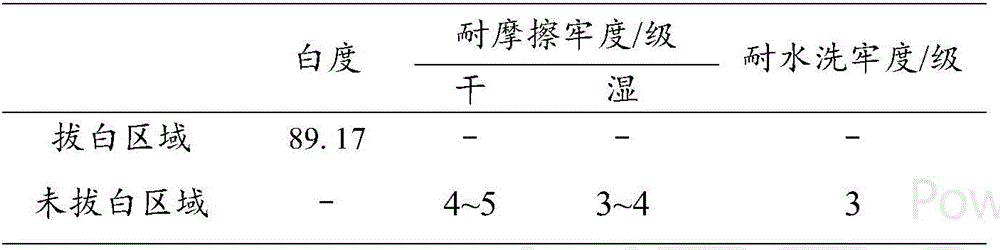

Embodiment 3

[0045] The formula of the sizing agent is as follows: 5% sodium alginate is used as a thickener, 2% urea is used as a hygroscopic agent, 3% ammonium sulfate is used as an acid-base agent, and water is added to make up to 100%. Stir fully until the sodium alginate is fully swollen, and all components are completely dissolved and evenly dispersed.

[0046] The dyed wool fabric is padded with sizing solution and then dried, and the fabric is sprayed with white ink by an inkjet printer, and dried at room temperature. Then carry out steaming, the steaming temperature is 101° C., the steam saturation is 98%, and the time is 15 minutes. After the steaming is completed, the fabric is washed with water to obtain the ink-jet discharge printed fabric. After testing, the whitening area: the whiteness is 80.02; the non-whitening area: the dry rubbing fastness can reach grade 5, the wet rubbing fastness can reach grade 4-5, and the washing fastness can reach grade 3-4. The test results ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com