A kind of preparation method of transfer printing fabric

A technology for transferring printing paper and fabric, applied in dyeing method, textile and papermaking, etc., can solve the problems of complicated process, large amount of pulp, water pollution, etc., and achieve the effect of simple operation, strong color contrast, and reduced emission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

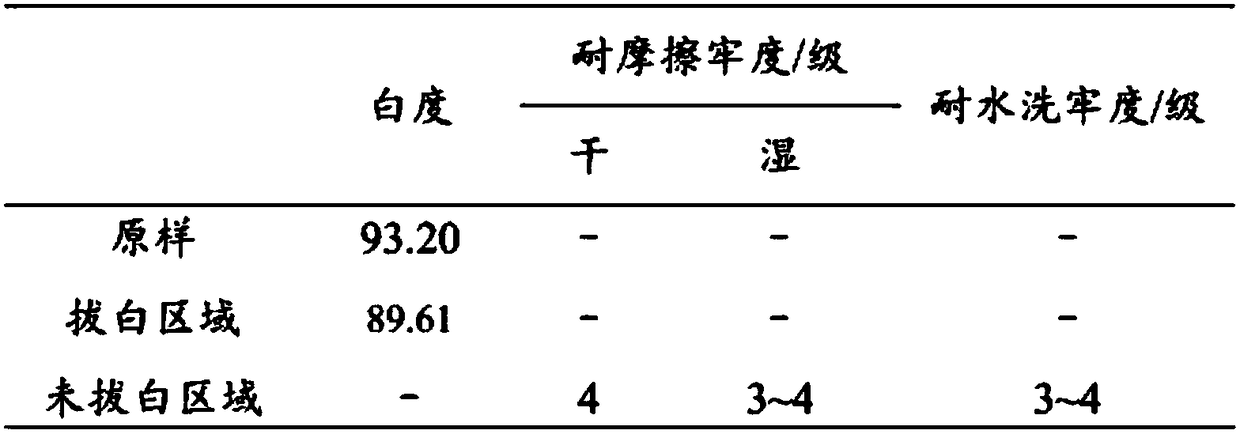

Embodiment 1

[0033] The white ink formula is,

[0034] 8% formaldehyde-free whitening agent, 8% N-methylpyrrolidone as a solubilizer, 6% caprolactam as a humectant, 0.8% sodium hexametaphosphate as an additive, 1.2% pH regulator and 76% deionized water are mixed together , and fully stirred for 30 minutes to obtain a white ink mixed solution, during which the dissolution of each component can be accelerated by heating.

[0035] The modified coating agent formula is,

[0036] Water-soluble hot-melt adhesive: 0.5% water-solvent polyester hot-melt adhesive;

[0037] Polymer thickener: 3% hydroxypropyl cellulose, 0.7% sodium carboxymethyl cellulose, 0.5% modified starch;

[0038] Printing and dyeing auxiliaries: moisture absorbent is 5% urea, color fixing agent is 3% dicyandiamide, alkali agent is 2% sodium carbonate, 2% trichloroacetic acid, physical adsorption agent is 0.5% nano silicon dioxide, add water to make up to 100 %. Stir well until completely dissolved.

[0039] The transfer s...

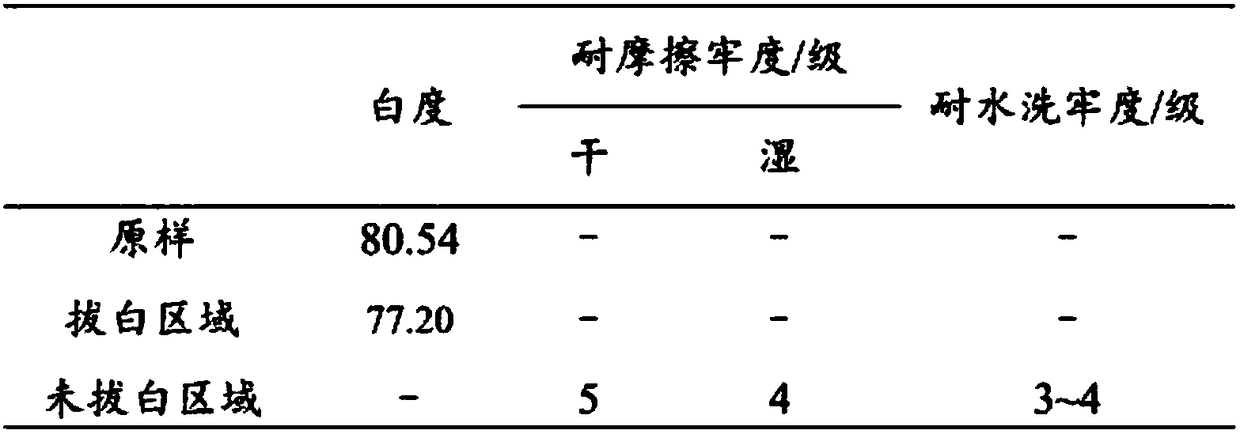

Embodiment 2

[0046] The white ink formula is,

[0047] 8% formaldehyde-free whitening agent, 8% N-methylpyrrolidone as a solubilizer, 6% caprolactam as a humectant, 0.8% sodium hexametaphosphate as an additive, 1.2% pH regulator and 76% deionized water are mixed together , and fully stirred for 30 minutes to obtain a white ink mixed solution, during which the dissolution of each component can be accelerated by heating.

[0048] The formula of the modified coating agent is:

[0049] Water-soluble hot-melt adhesive: 5% water-solvent polyurethane hot-melt adhesive,

[0050] Polymer thickener: 3% sodium alginate,

[0051] Printing and dyeing auxiliaries: hygroscopic agent is 8% glycerin, color fixing agent is 0.5% dicyandiamide, alkaline agent is 2% sodium bicarbonate, physical adsorption agent is 0.5% nano silicon dioxide, add water to make up to 100%. Stir well until completely dissolved.

[0052] The transfer substrate is evenly coated on the transfer printing base paper with a coating ...

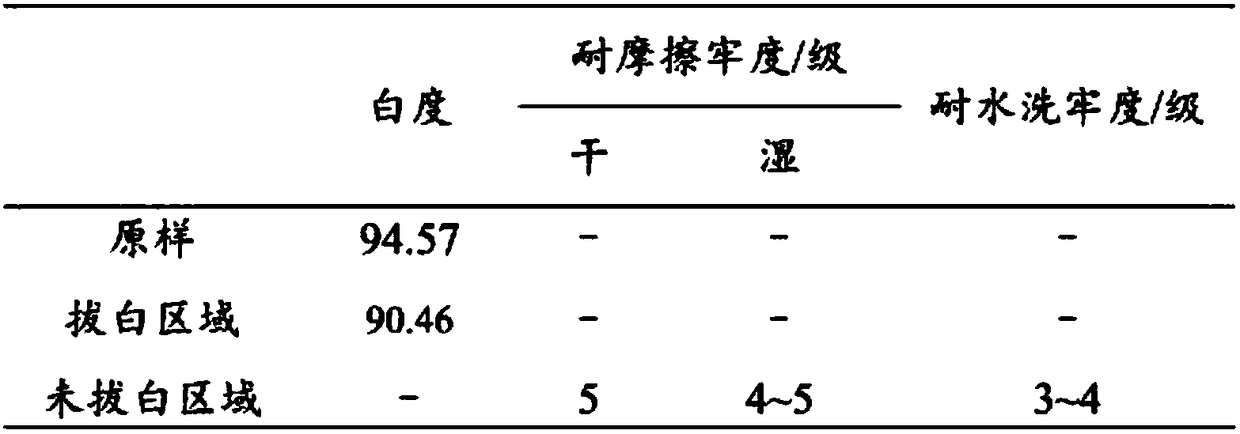

Embodiment 3

[0059] The white ink formula is,

[0060] 8% formaldehyde-free whitening agent, 8% N-methylpyrrolidone as a solubilizer, 6% caprolactam as a humectant, 0.8% sodium hexametaphosphate as an additive, 1.2% pH regulator and 76% deionized water are mixed together , and fully stirred for 30 minutes to obtain a white ink mixed solution, during which the dissolution of each component can be accelerated by heating.

[0061]The formula of the modified coating agent is:

[0062] Water Soluble Hot Melt Adhesive: 3% Water Solvent Polyester Hot Melt Adhesive

[0063] Polymer thickener: 4% guar gum, 1% sodium carboxymethyl cellulose;

[0064] Printing and dyeing auxiliaries: diluent is 10% urea, color fixing agent is 0.5% dicyandiamide, printing and dyeing auxiliaries is 2% sodium bicarbonate, physical adsorption agent is 0.5% nano silicon dioxide, add water to make up to 100%. Stir well until completely dissolved.

[0065] The transfer substrate is uniformly coated on the transfer print...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com