Method for combining concrete base of offshore supporting structure and steel pipe pile

A supporting structure and concrete technology, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of increased wave force, long time, and difficult construction of the supporting structure, and achieve the effect of firm combination and prevention of water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]Preferred embodiments of the present invention constructed as described above will be described below with reference to the accompanying drawings. The drawings and their descriptions are examples to facilitate the understanding of the present invention by those skilled in the art, and it should be understood that they are not intended to limit the idea and scope of the present invention.

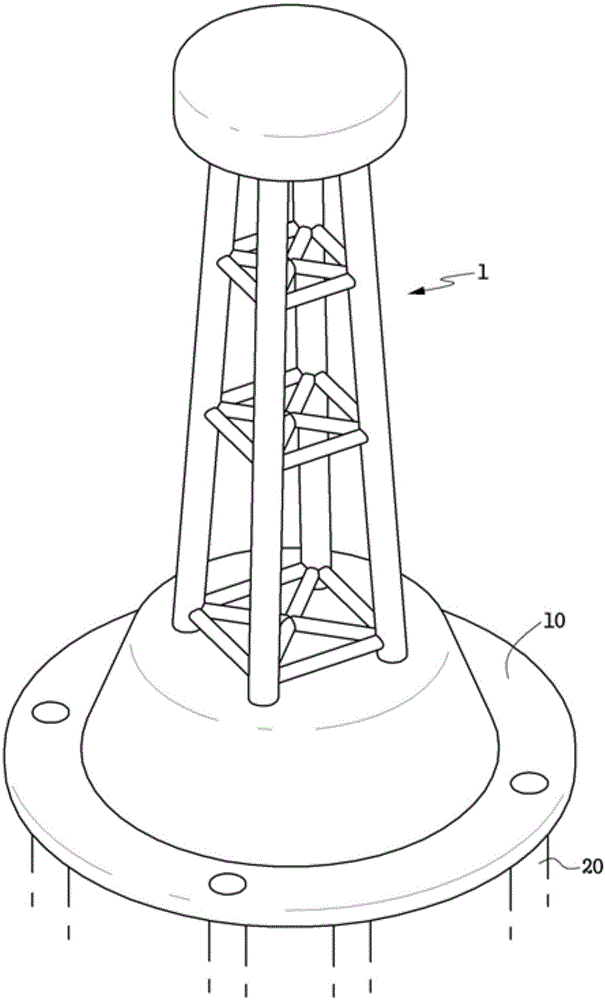

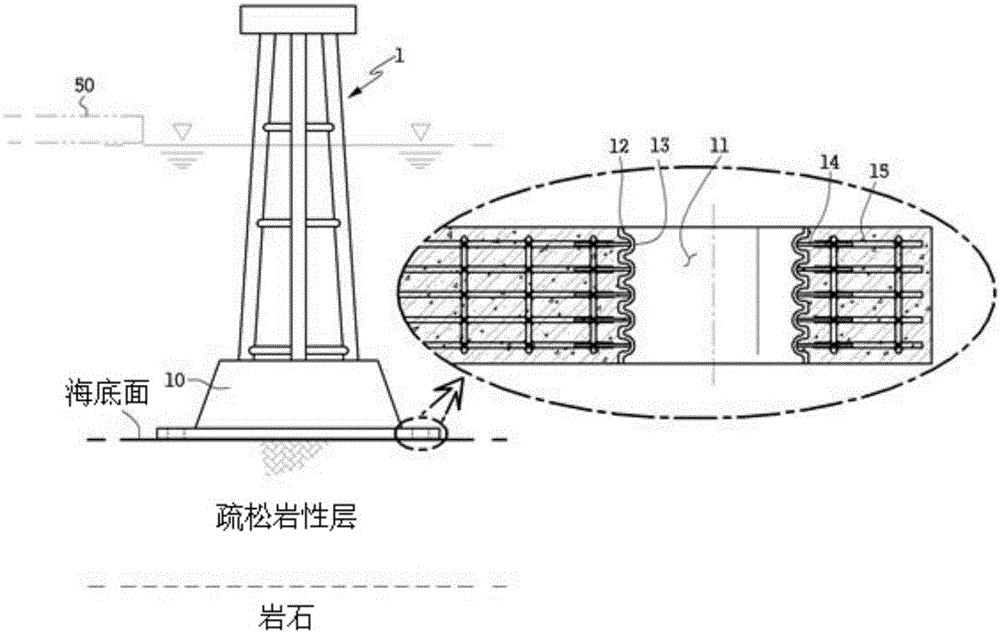

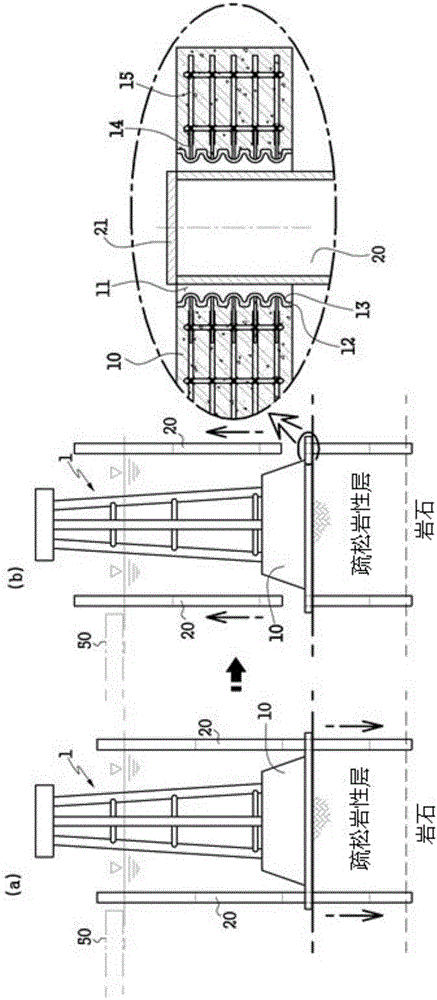

[0044] figure 1 To show a sectional view of an offshore support structure incorporating steel pipe piles of the present invention, Figures 2a to 2g is a drawing showing step by step the bonding method between the concrete base of the offshore support structure and the steel pipe piles of the present invention, image 3 It is a flow chart of the bonding method between the concrete base of the offshore support structure and the steel pipe piles of the present invention.

[0045] The present invention relates to a method of bonding steel pipe piles 20 to a concrete base 10 of an offsho...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap