Assembly type wood structure house wall and floor grating connecting joint and construction method

A technology for connecting nodes and wooden structures, which is applied in the direction of building construction and construction, and can solve problems such as cumbersome construction, slow construction speed, and difficulty in ensuring connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

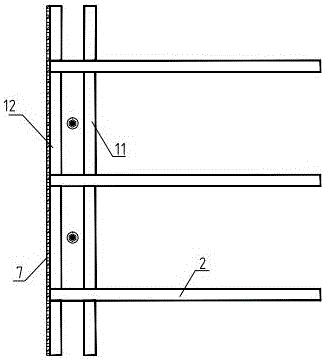

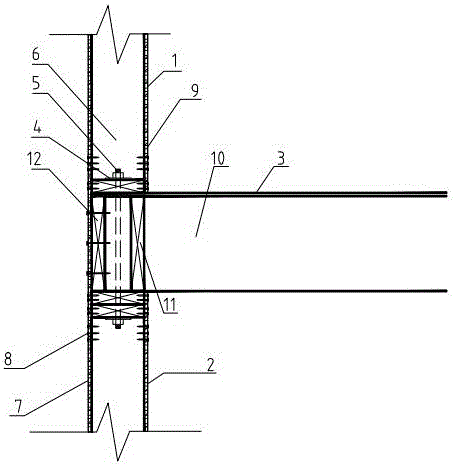

[0018] A connection node between the wall and the floor grid of a prefabricated wooden structure house, including a wall, a grid floor 3, a steel backing plate 4, and connecting bolts 5. The wall is a wooden component, and the middle part of the wall has a Wooden skeleton 6, the outer side of the wooden skeleton 6 is connected to the OSB board 7 outside the wall, the OSB board 7 outside the wall is locked with the wooden skeleton 6 by tacks 8, the inner side of the wooden skeleton 6 is connected to the OSB board 9 inside the wall, the The OSB board 9 on the inner side of the wall is locked with the inner side of the wooden skeleton 6 through tacks 8 , and the wall includes an upper wall body 1 and a lower layer wall body 2 .

[0019] The grid floor 3 is a wooden member, the middle part of the grid floor 3 has a wooden keel 10, and the inner wall of the woo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com