Plasma synthetic jet serial discharge device and method based on marx generator

A plasma and synthetic jet technology, applied in the direction of using plasma, thrust reverser, machine/engine, etc., can solve the problems of few synchronous discharge schemes for multi-channel actuators, complex power supply structure, complex discharge structure, etc., and achieve high practicality Application value, realization of interference and control, effect of wide-range flow field control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

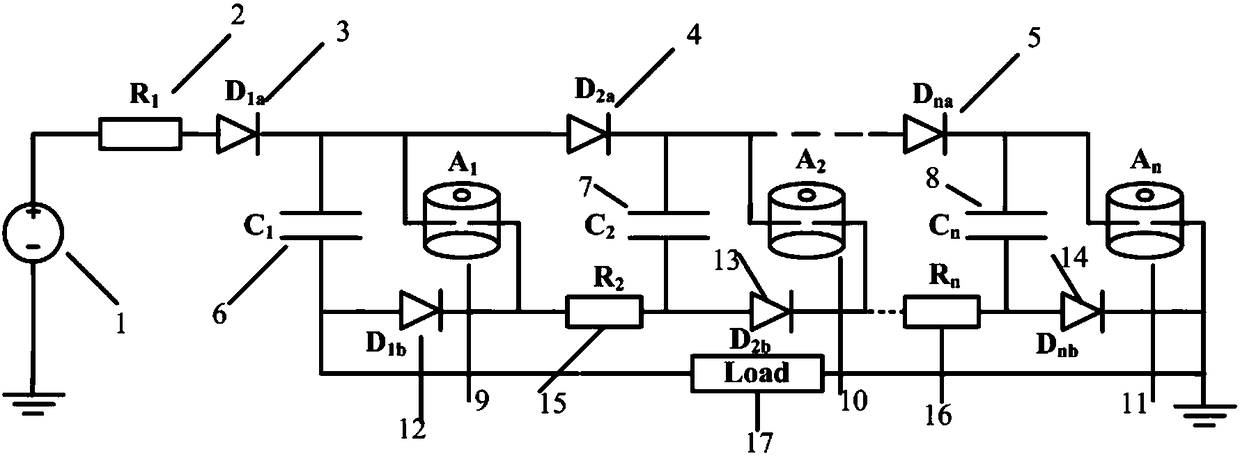

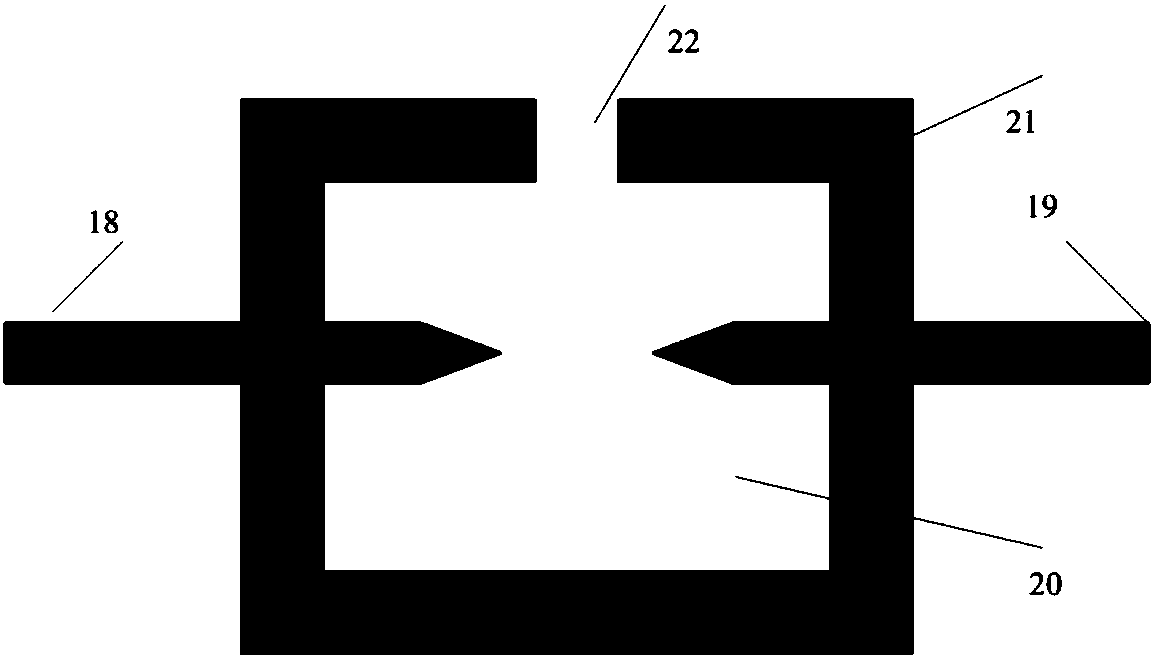

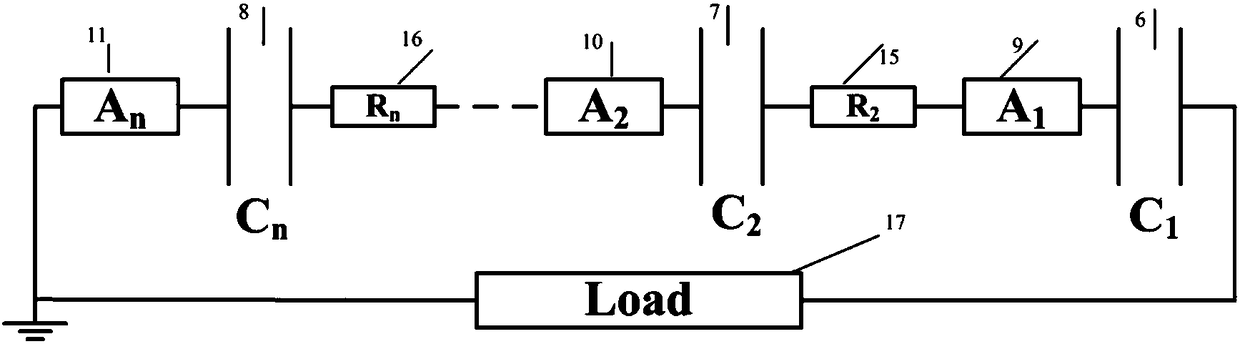

[0034] Example 1, such as figure 1 As shown, a kind of plasma synthetic jet serial discharge device based on the Marx generator of the embodiment of the present invention includes a DC source 1, a charging resistor 2 (R 1 ), multiple charging diodes (D 1a 、D 2a ,...,D na ), multiple charging capacitors (C 1 、C 2 ,...,C n ), multiple plasma synthetic jet actuators (A 1 、A 2 ,...,A n ), multiple discharge diodes (D 1b 、D 2b ,...,D nb ), multiple discharge resistors (R 2 ,...,R n ) and a load 17, wherein the plasma synthetic jet actuator is a two-electrode plasma synthetic jet actuator, and the load 17 can be other types of discharge loads in the high voltage field. The negative pole of the DC source is grounded, the positive pole of the DC source is connected to one end of the charging resistor, the other end of the charging resistor is connected to the positive poles of multiple charging diodes, the negative poles of the multiple charging diodes are respectively co...

Embodiment 2

[0039] Embodiment 2, the present invention also provides a discharge method based on a Marx generator-based plasma synthetic jet series discharge device, the method comprising:

[0040] Step 1, adjusting the distance between the two electrodes of each plasma synthetic jet actuator, and keeping the electrode distances of n plasma synthetic jet actuators consistent.

[0041] Step 2, increase the output voltage U of the DC source 1, n charging capacitors pass through the charging resistor R 1 (2) Finally, parallel charging is realized. At this time, the capacitance values of the n charging capacitors are the same.

[0042] Step 3, when the voltage on the charging capacitor reaches the breakdown voltage of the plasma synthetic jet actuator, the n plasma synthetic jet actuators break down synchronously, forming a high-current spark discharge, and simultaneously generating n channels of high-speed plasma synthetic jet jet.

[0043] Step 4, n charging capacitors, n plasma synthet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com