Special-purposed fan assembling and detecting device and circle run-out detection method

A detection equipment, a technology of circular beating, applied in the direction of measuring devices, instruments, etc., can solve the problems that the fan cannot accurately control the screw torque, the wind speed cannot meet the requirements, and increase the fan beating phenomenon, so as to ensure the stability and consistency, Guarantee reliability and accuracy, and ensure the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

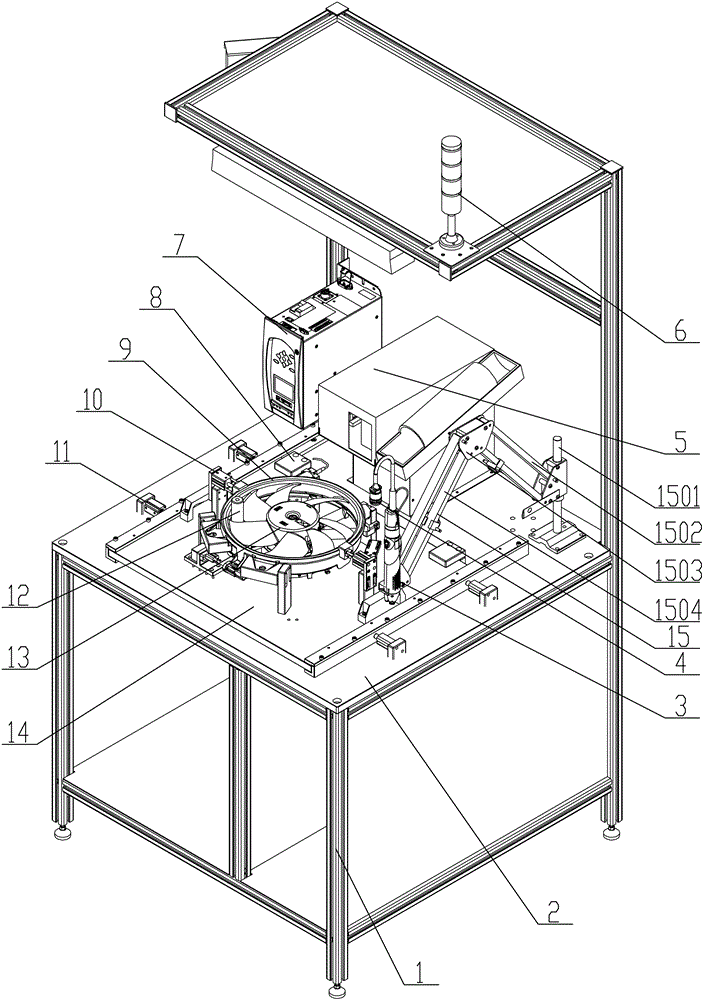

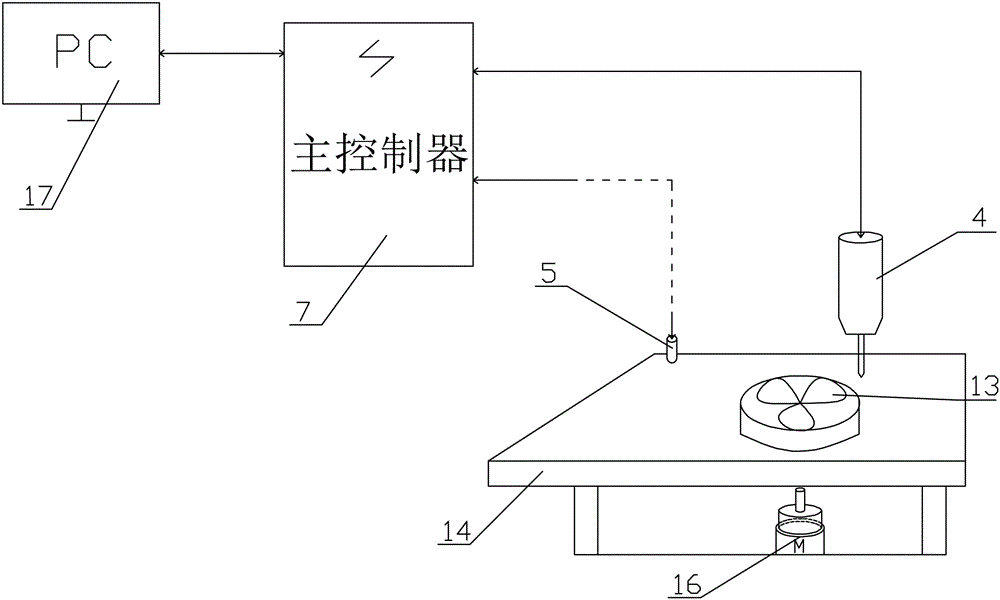

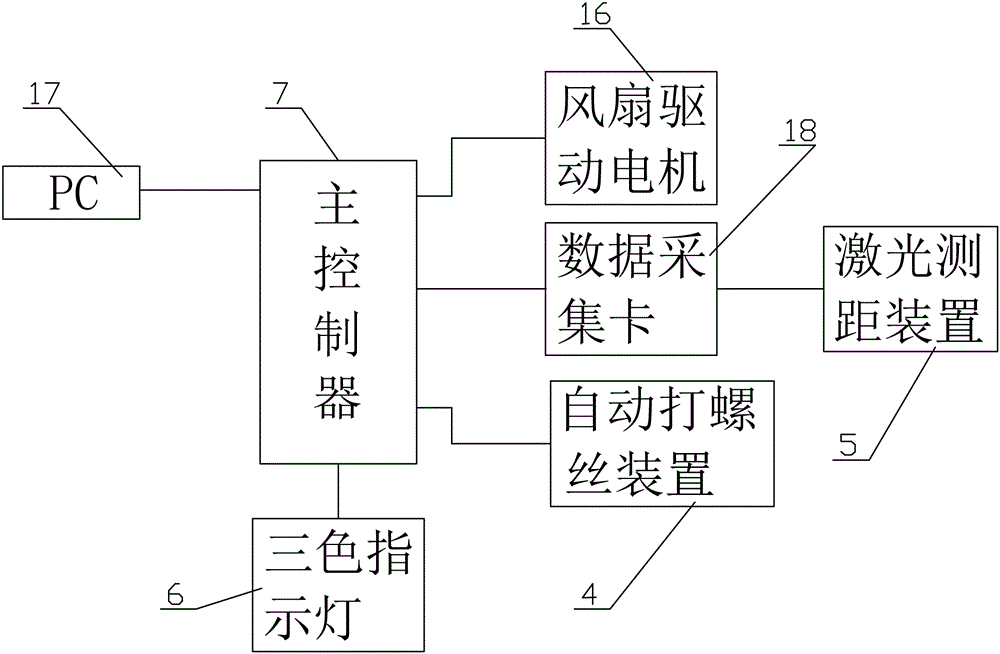

[0034] Such as Figure 1-3 As shown, the special fan assembly and detection equipment includes a frame 1, a workbench 2 is fixed on the top of the frame 1, and a detection platform 14 is fixedly installed on the workbench 2 through a clamping cylinder 11. The detection The platform 14 is provided with a fixture, and the bottom surface of the workbench 2 is equipped with a fan drive motor 16, and the fan drive motor 16 is arranged directly below the detection platform 14, and a laser distance measuring device is provided directly above the detection platform 14. Device 5, the laser distance measuring device 5 is fixedly installed on the workbench 2, the laser distance measuring device 5 is connected to the main controller 7 through a data acquisition card 18, and an automatic screwing device is installed on the side of the workbench 2 4. The automatic screwing device 4 is connected with the screw feeding cylinder 3, and the screw feeding cylinder 3 is installed on the vertical ...

Embodiment 2

[0043] The circular runout detection method is carried out by fan assembly and detection equipment, which includes the following steps:

[0044] In the first step, according to the model of the fan 13 to be tested, input the product ID, circular runout range, fan screw rotation safety angle and fan screw safety torque in the industrial computer PC17, and then install the fan 13 to be tested through the fixed cylinder 10 On the detection platform 14, push the detection platform 14 so that it is located directly below the laser distance measuring device 5, and then fix the detection platform 14 by clamping the cylinder 11;

[0045] The second step is to start the laser distance measuring device 5, and according to the in-place signal returned by the laser distance measuring device 5, start the cylinder to fix the fan base, and fix the fan rotation hole and the main shaft of the fan drive motor 16 well;

[0046] The third step is to manually operate the automatic screwing device ...

Embodiment 3

[0050] A fan assembly, detection equipment and circular runout detection method, used for assembly and detection of fans in automotive air-conditioning systems, so as to meet the circular runout requirements, ensure the stability of fan rotation, reduce the noise of fan rotation, and reduce friction during fan rotation Wear, prolong service life, improve product quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com