Grinding machine grinding chatter fault on-line diagnosis method

A technology of grinding chatter and diagnosis method, which is applied in measuring devices, instruments, and measuring ultrasonic/sonic/infrasonic waves, etc., and can solve problems such as short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and tables.

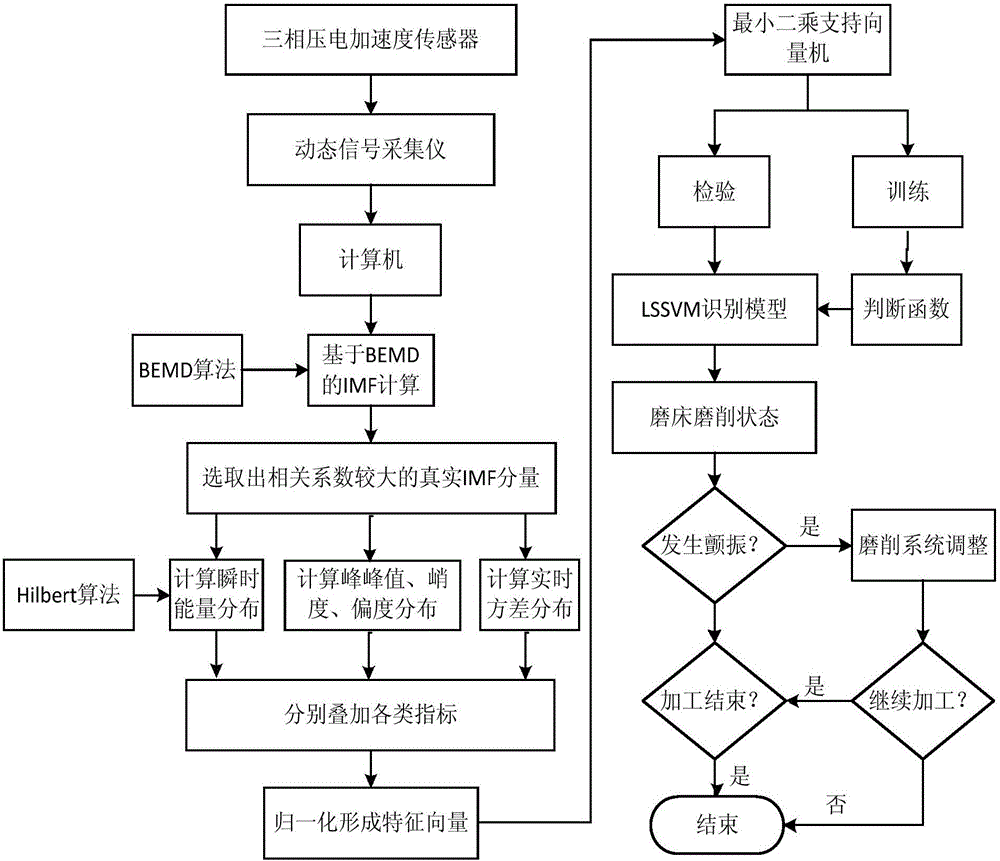

[0072] figure 1 For the overall implementation flow chart of the present invention, the fast and effective flutter identification method of the present invention comprises the following steps:

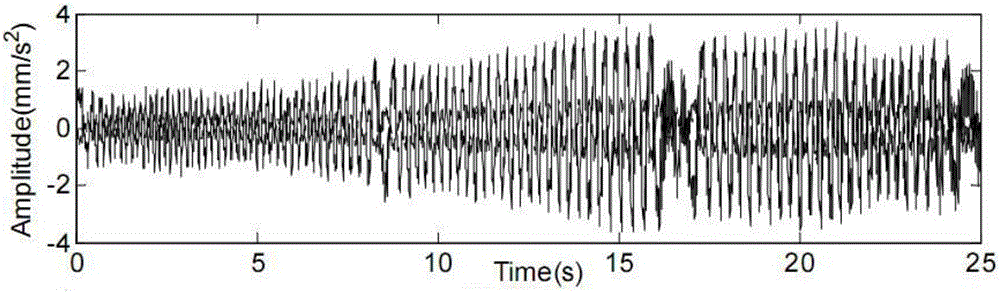

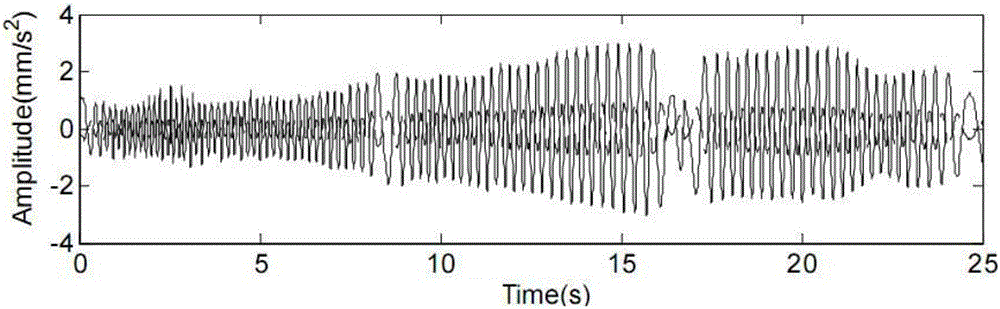

[0073] S1: First, use the vibration signal acquisition system to collect the vibration signal of the grinding machine. The vibration signal acquisition system includes a three-phase piezoelectric acceleration sensor, a dynamic signal test and analysis system and a computer. The three-phase piezoelectric acceleration sensor is arranged on the main shaft, motor and column of the grinding machine. By changing the grinding parameters of the grinding machine (grinding wheel speed, feed speed and grinding depth), a total of 80 sets of tests were carried out, and 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com