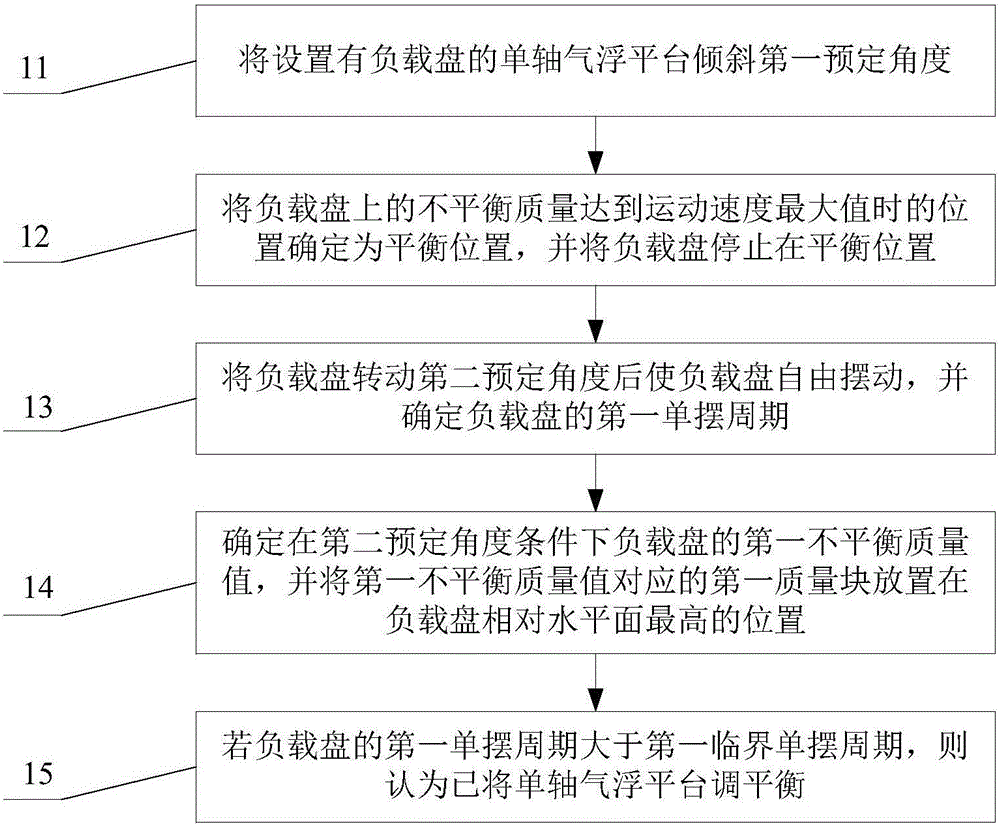

Single shaft air floating table balance adjusting method and system

An air floating platform and balancing technology, which is applied to static/dynamic balance testing, measuring devices, instruments, etc., can solve the problems of low balance adjustment accuracy, and achieve the effect of high adjustment balance accuracy, simple structure and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

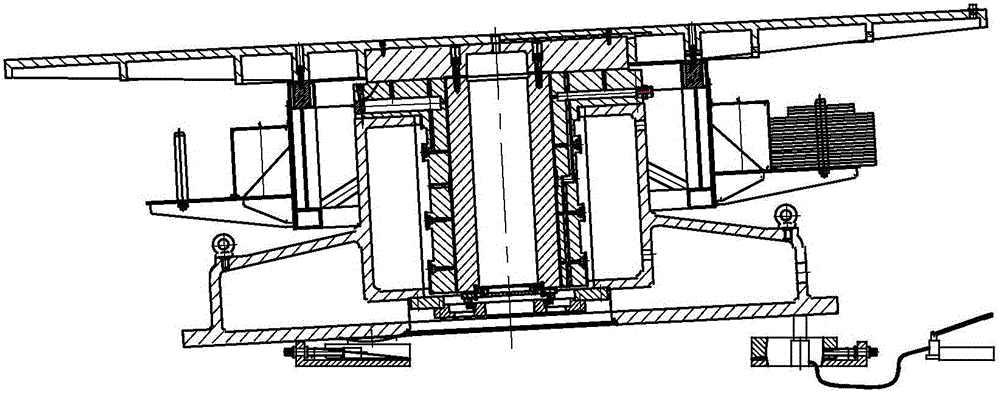

Method used

Image

Examples

Embodiment 1

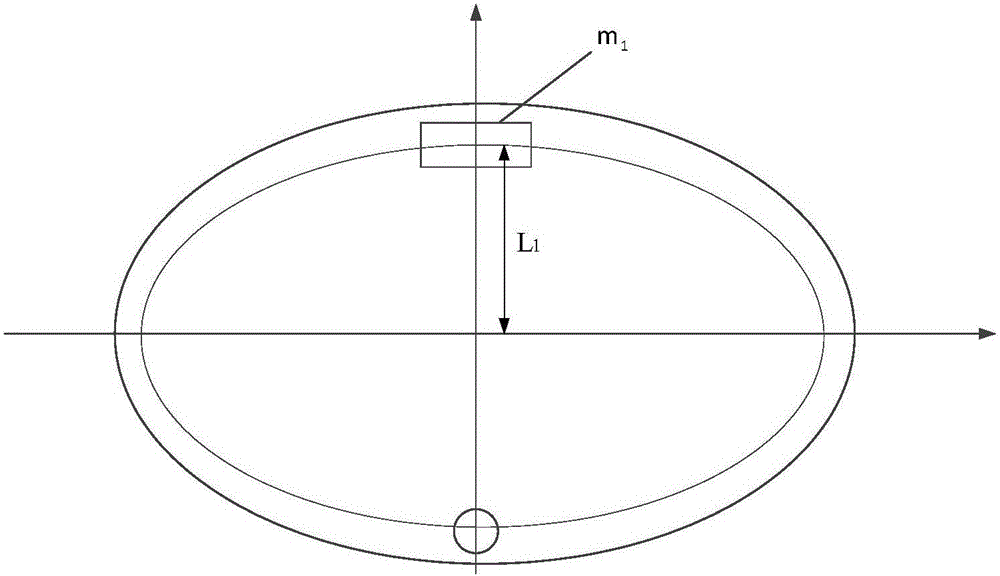

[0078] First, the formula for calculating the unbalanced mass value is derived:

[0079] Tilt the single-axis air bearing platform at an angle θ, such as Figure 9 As shown, when the load plate rotates due to inclination, its unbalanced mass provides a moment to make the load plate perform a simple pendulum motion. According to the moment balance, the following calculation formula is obtained:

[0080] Jα=Gsinθsin x L (1)

[0081] Among them, J represents the moment of inertia of the load plate, α represents the angular acceleration of the load plate, G represents the gravity of the unbalanced mass block, θ represents the inclination angle of the single-axis air bearing platform, and x represents the current position of the load plate to balance when it is doing a single pendulum motion. Angle of position.

[0082] Use the following calculation formula to calculate the period of simple pendulum motion:

[0083] J d ...

Embodiment approach 1

[0114] In the process of deriving the calculation formula of the unbalanced mass value, for the convenience of derivation, sinx≈x is taken, so the larger the degree x is, the greater the period error of the pendulum calculated in the calculation formula is, so try to change the swing angle during each test process Keep it within 20°, so that the accuracy of calculating the unbalanced mass value can be improved.

Embodiment approach 2

[0116] In the step of adjusting the balance, the cycle of the simple pendulum of the load plate can be measured multiple times, so that the accuracy of the measurement cycle can be increased, and the accuracy of calculating the unbalanced mass can be improved. The test process should be conducted in a closed environment as much as possible to avoid the impact of wind resistance and other environmental influences on the measurement results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com