Automatic no-water pressure tester

A pressure testing machine and automatic technology, which is applied in fluid tightness testing, machine/structural component testing, and by measuring fluid growth and deceleration rates, can solve the pressure on enterprises to increase costs, affect the efficiency of detection, increase Equipment investment and other issues to achieve the effect of saving labor costs, improving detection efficiency, and saving drying links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

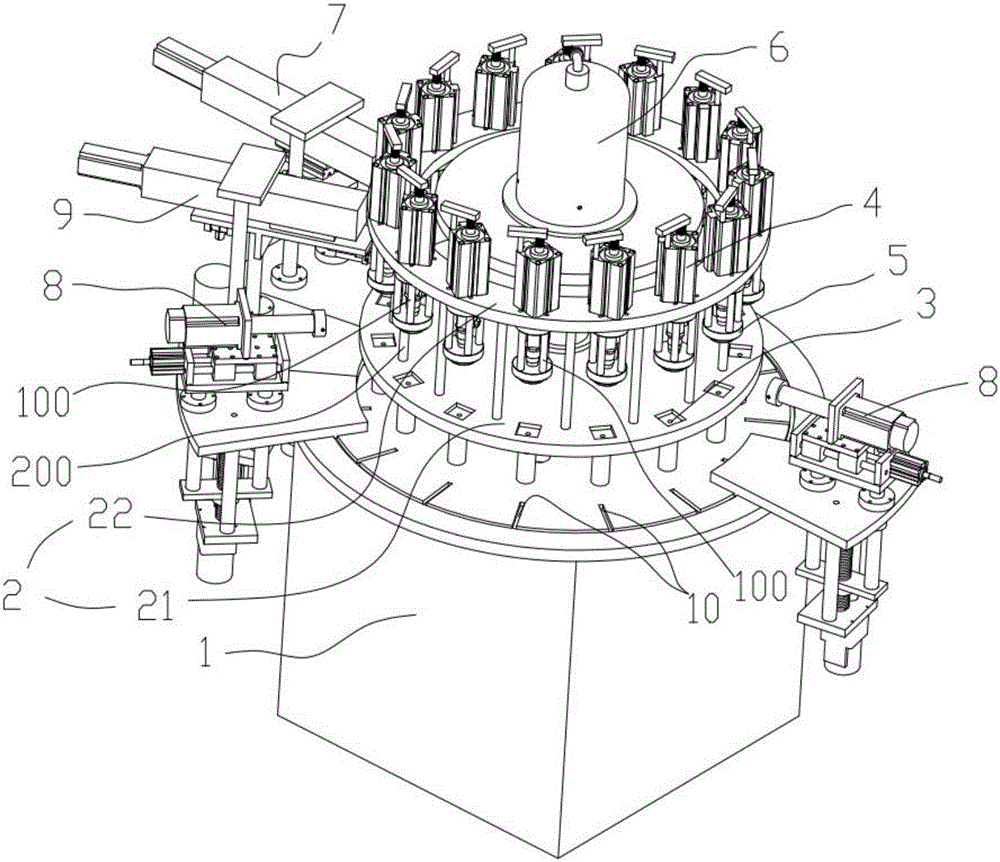

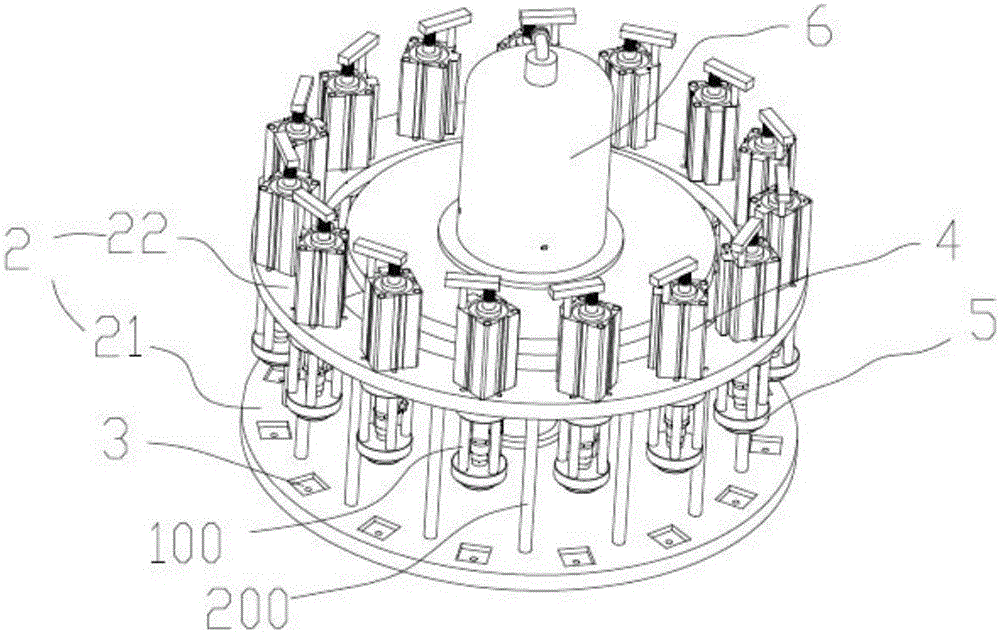

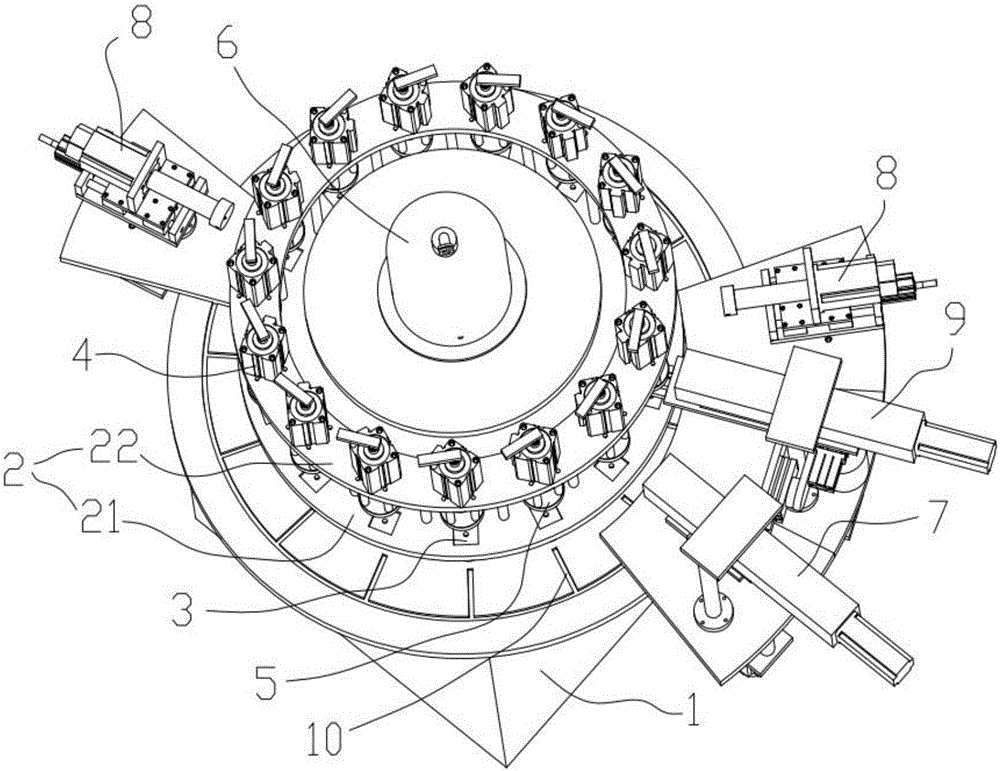

[0025] see Figure 1 ~ Figure 3 As shown, an automatic anhydrous pressure test machine includes a machine base 1, on which an intermittent turntable 2 is arranged; on the intermittent turntable 2, several waiting stations 3 for placing valves to be checked are arranged, Above each station to be inspected, a lift cylinder 4 is correspondingly arranged; a sensor monitoring device 5 is arranged at the lower end of the lift cylinder 4; Compressor air storage tank 6; feed unit 7, torque unit 8 and discharge unit 9 are arranged on the outer periphery of the intermittent turntable 2, and the feed unit 7, torque unit 8 and discharge unit 9 are fixed on the machine base 1 . The invention adopts automatic multi-station to detect whether there is air leakage on the outside and inside of the valve. The detection process is detailed and orderly, and the struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com