Concrete sample polishing device for nanometer indentation experiments

A technology of concrete specimens and nano-indentation, which is applied in the direction of measuring devices, test sample preparation, sampling, etc., can solve the problems of time-consuming and labor-intensive sectioning precision, etc., and achieve the effect of convenient grinding, good grinding effect and full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

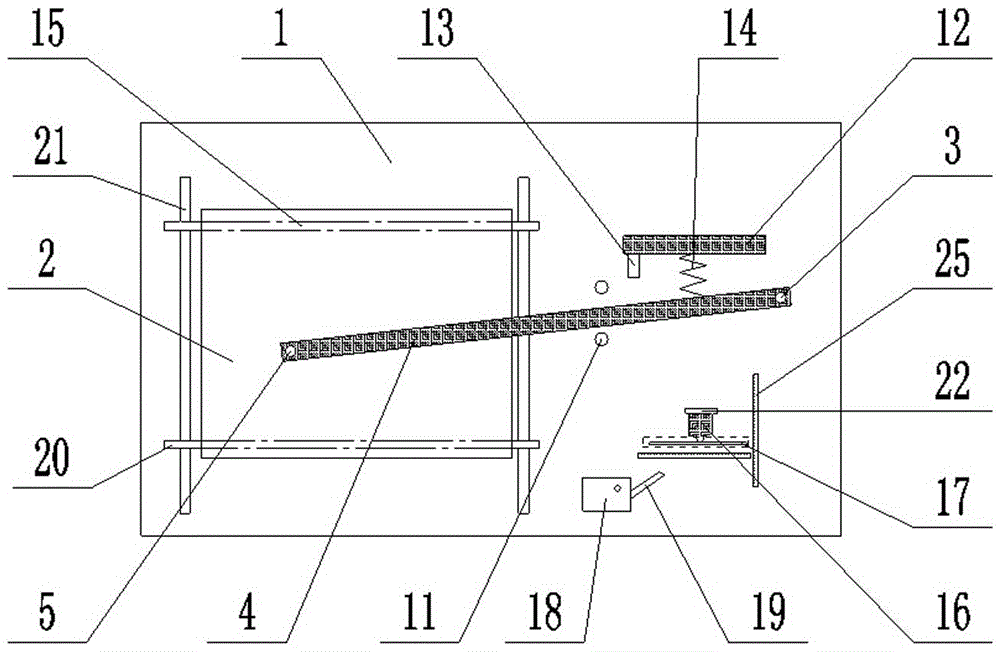

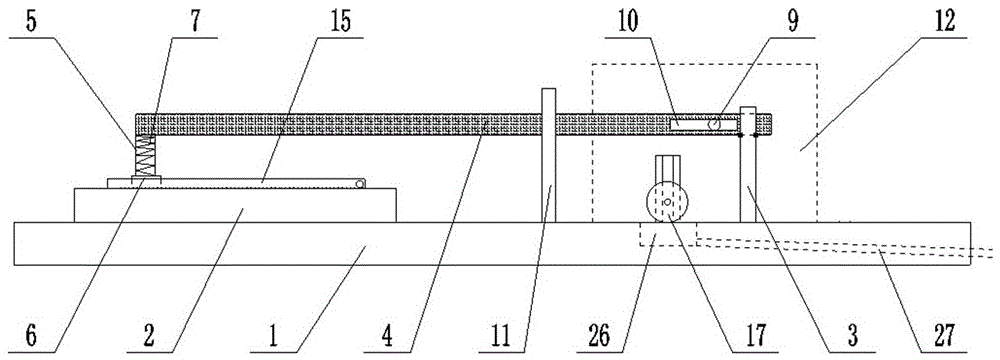

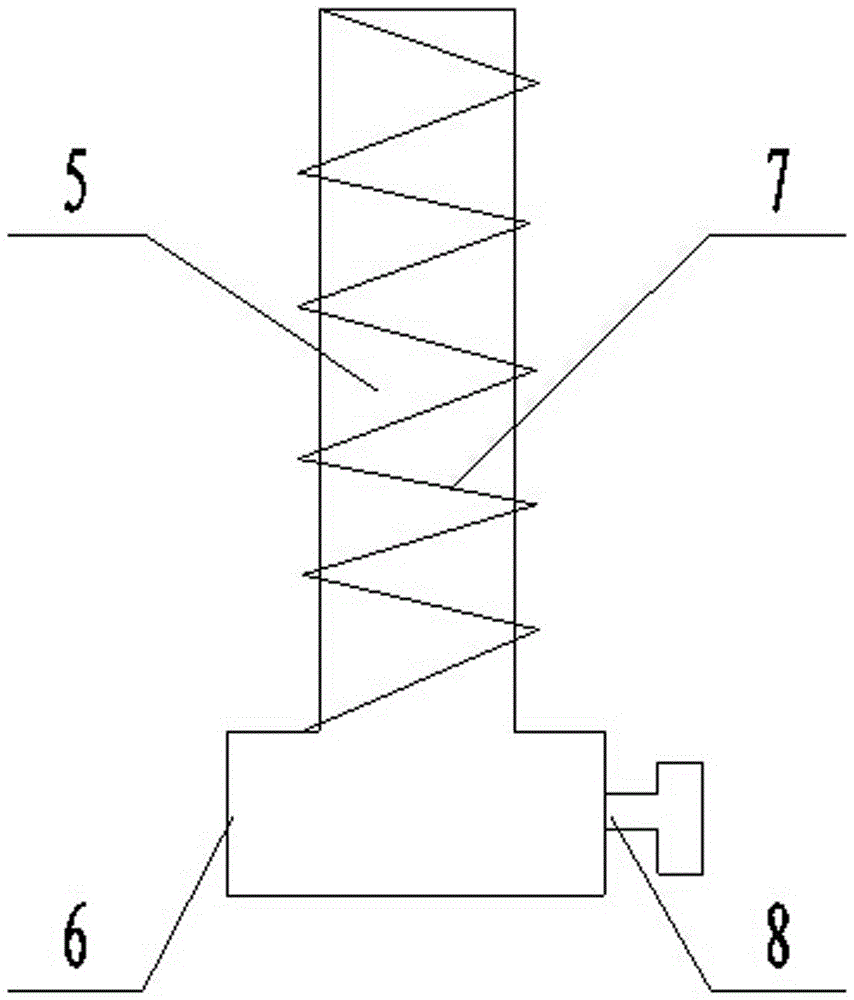

[0017] The nano-indentation concrete specimen light-sectioning device includes a base platform 1, and a sandpaper fixing table 2 and a vertical rotating shaft 3 distributed front and rear are arranged on the base platform 1; The rotating arm 4 above the table 2, the front end of the rotating arm 4 is provided with a polishing rod 5 located below it, the lower end of the polishing rod 5 is provided with a test piece box 6, and the polishing rod 5 is covered with a rotating arm 4 and a test piece box 6 The push spring 7 between them, the side wall of the test piece box 6 is provided with a locking bolt 8, the rear part of the rotating arm 4 is provided with a horizontal rotating shaft 9, and a latch 10 is worn on the rotating arm 4; the left and right sides of the rotating arm 4 Limit rods 11 are all arranged, and the left and right sides of the rotating arm 4 are provided with a support 12, and the support 12 is provided with an AC electromagnet 13 and a rotating spring 14 conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com