Method for detecting lithium content in lithium battery cathode material mixture

A cathode material and mixing technology, which is applied in the direction of analyzing the material by chemical reaction, analyzing the material by observing the influence on the chemical indicator, and performing chemical analysis by titration, etc. It can solve the problem of expensive ICP instruments, dilution, etc. error, non-environmental protection and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

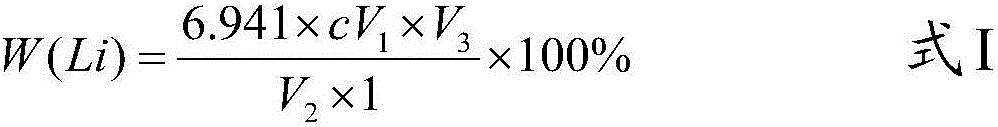

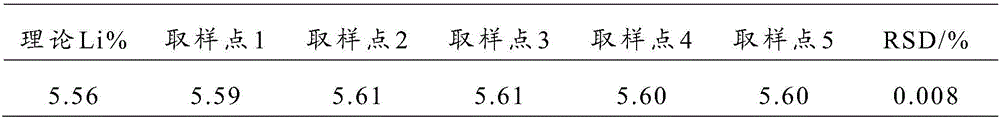

[0056] Three samples were taken respectively at 5 different sampling points in a lithium battery cathode material-mixture with lithium carbonate as a lithium source, and the method provided by the invention was used to detect the content of lithium element wherein, the average detection result of each sampling point And the theoretical values are shown in Table 1 below:

[0057] Table 1 Test results of 5 sampling points

[0058]

[0059] As can be seen from Table 1, each sampling point is very close to the theoretical value, and the relative standard deviation RSD is very low, which shows that the method accuracy provided by the present invention is high, only 0.008%, which shows that the method precision provided by the present invention is also high , indicating that the above sample has been fully mixed evenly.

experiment example 2

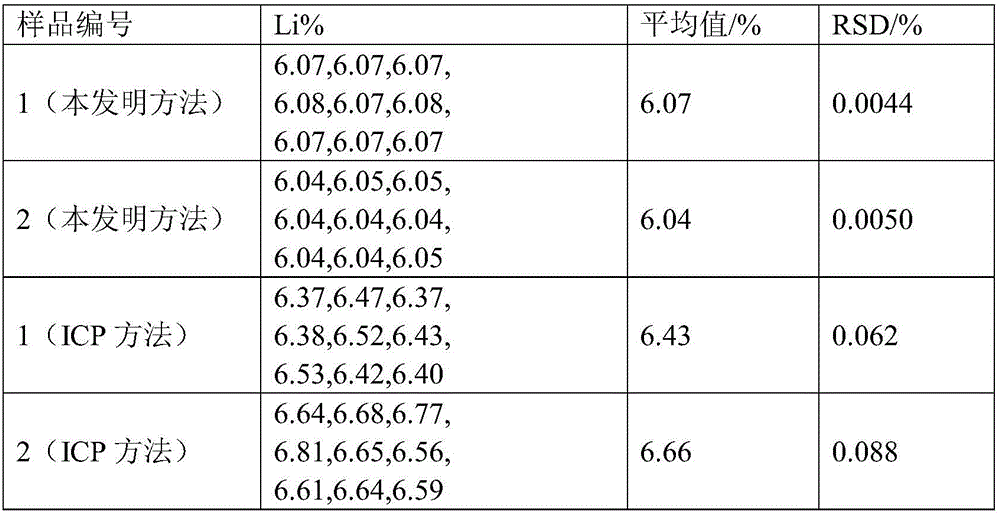

[0061] Carry out lithium content test with the present invention and ICP method respectively to two samples, the result is as shown in table 2 below,

[0062] The result of table 2 inventive method and ICP method testing lithium content

[0063]

[0064] As can be seen from Table 2, for sample 1, the RSD (relative standard deviation) detected by the method of the present invention is 0.0044%, while the RSD (relative standard deviation) detected by the ICP method is 0.062%, a difference of nearly 15 times;

[0065] For sample 2, the RSD (relative standard deviation) detected by the method of the present invention is 0.0050%, while the RSD (relative standard deviation) detected by the ICP method is 0.088%, a difference of nearly 17 times;

[0066] It can be seen that the RSD (relative standard deviation) of the results detected by the method of the present invention is smaller, indicating that the results detected by the method of the present invention are more stable, and th...

experiment example 3

[0068] Detect lithium content in 6 different samples respectively with method of the present invention and ICP method, the result is as shown in table 3 below,

[0069] Table 3 Test results of 6 different samples

[0070] Sample serial number

Theoretical Liwt%

Liwt% of the present invention

ICP Liwt%

1

6.33

6.38

6.64

2

8.49

8.57

8.98

3

6.11

6.19

6.50

4

6.00

6.07

6.43

5

6.03

6.04

6.66

6

5.56

5.60

6.06

[0071] As can be seen from Table 3, the lithium content detected by the method provided by the invention is closer to the theoretical value (true value), while the lithium content obtained by the ICP method deviates greatly from the theoretical value.

[0072] It can also be seen from comprehensive experimental examples 1 to 3 that the method provided by the invention can achieve good detection for a mixture with a lithium content in the range of 5.56% to 8.49%, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com