An integrated frequency conversion fan cooling control device and its control method

A variable frequency fan and control device technology, applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problems of heat loss, large structure volume, etc., to improve reliability, low noise efficiency, avoid temperature rise overly effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

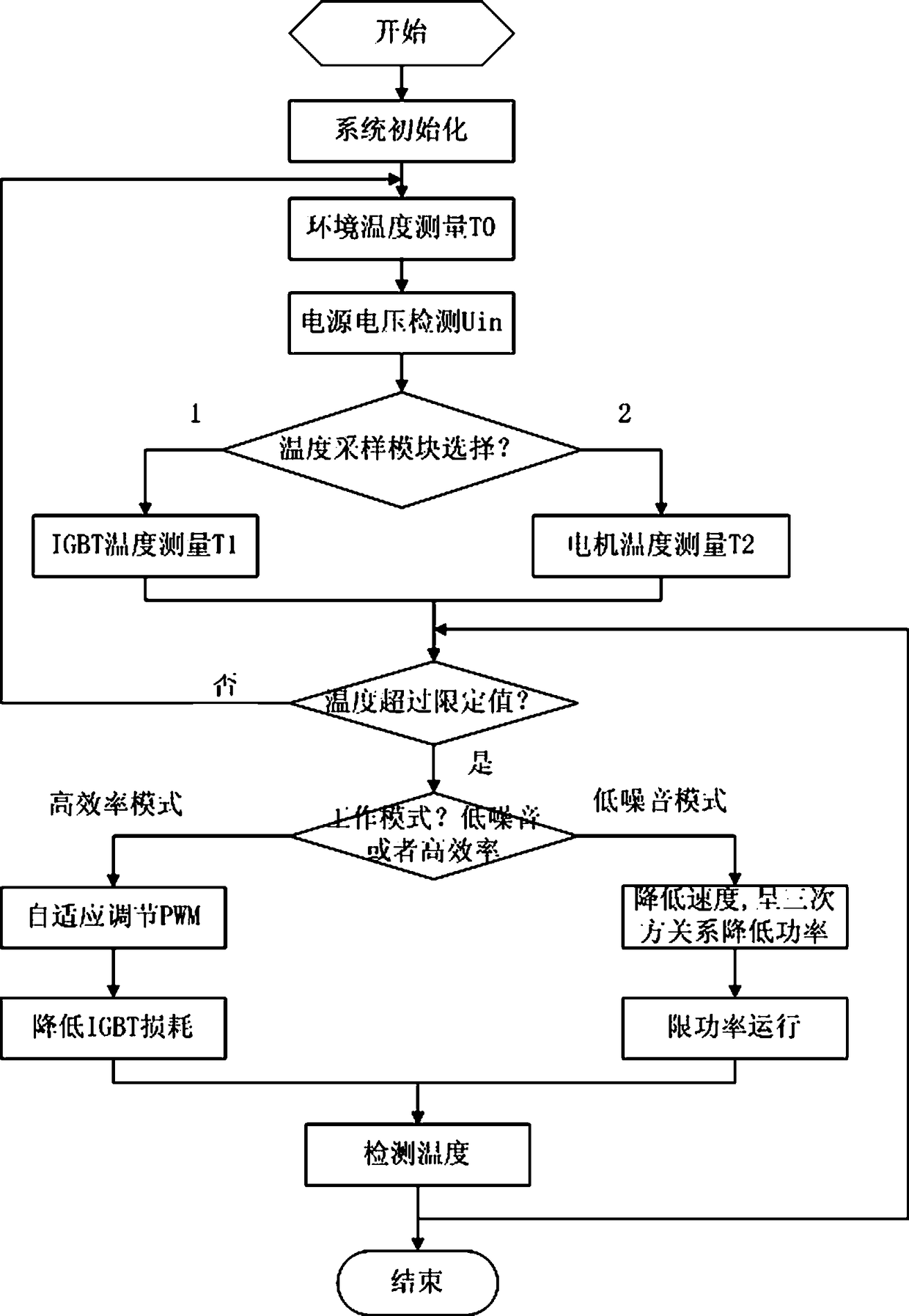

[0030] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

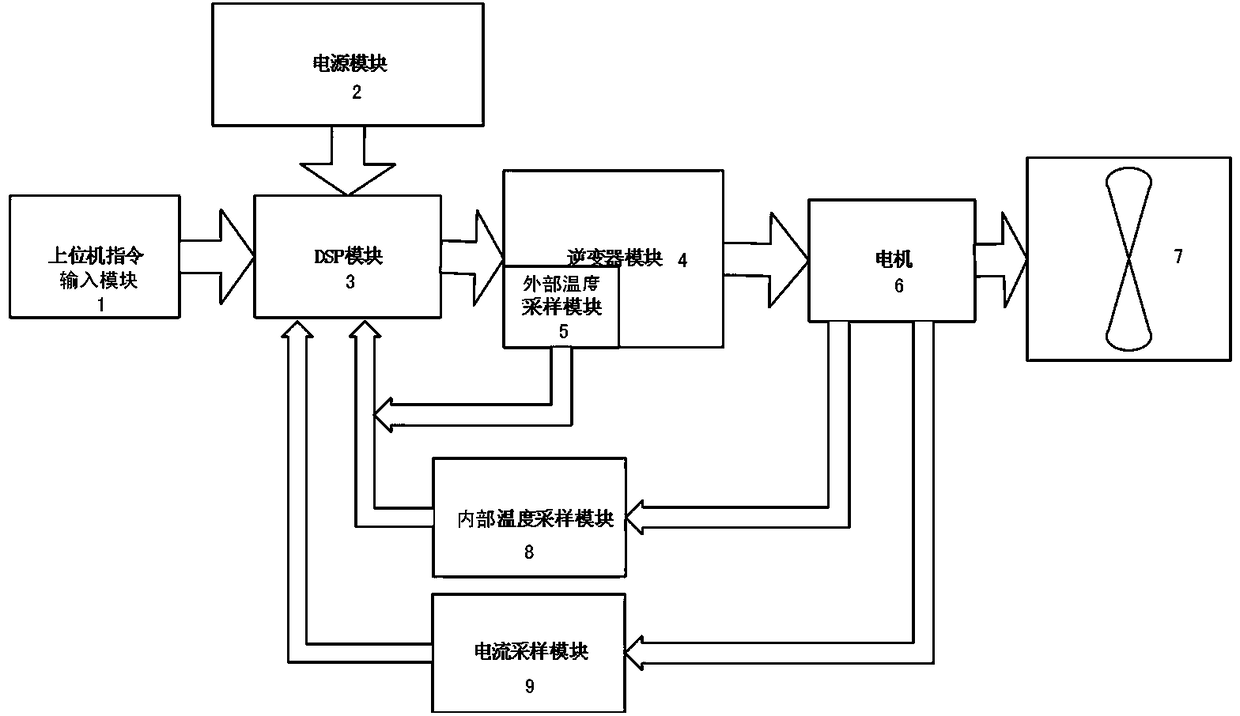

[0031] The technical solution is applicable to a variable frequency motor in which the motor and the frequency converter are integrated. The inverter fan is equipped with a frequency converter and a motor, wherein the frequency converter is equipped with a DSP module 3 and an inverter module 4, the output of the DSP module 3 is connected to the IGBT of the inverter module 4, the inverter module 4 is connected to the motor 6, and the motor 6 is a system actuator, which is used to drive the fan 7 to rotate; to realize the control of the motor 6 by the frequency converter.

[0032] Such as figure 1 As shown, the present invention includes a host computer instruction input module 1 for inputting instructions, a power supply module 2 for supplying power, a DSP module 3 for controlling the operation of an inverter module 4, and a DSP modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com