Crosstalk-resistant cable

An anti-crosstalk and cable technology, applied in the direction of insulated cables, power cables, cables, etc., can solve problems such as crosstalk of cable cores, and achieve the effect of reducing crosstalk, simple structure, and reducing bending degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0014] The present invention will be further described below in conjunction with accompanying drawing:

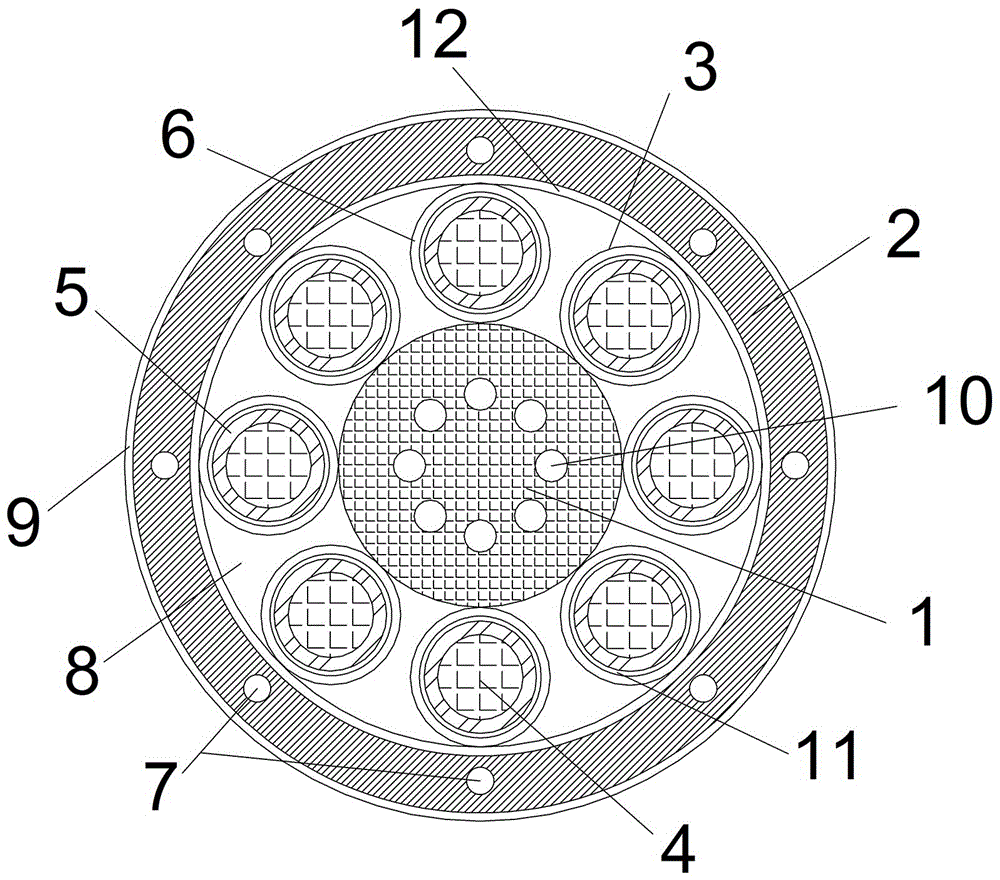

[0015] Such as figure 1 As shown, an anti-crosstalk cable includes an outer insulating layer 2 and a filler layer 1 inside the insulating layer 2. The insulating layer 2 includes a first phlogopite tape, a composite refractory tape and a second phlogopite mica tape from outside to inside. The composite refractory belt is calendered from a mixture of glass fiber cloth and ceramizable silicone rubber. The setting of glass fiber cloth helps to improve the strength when the ceramizable silicone rubber exhibits ceramic characteristics, and it is also convenient for the composite refractory belt. Forming; the cross-sections of the insulating layer 2 and the filler layer 1 are both circular, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com